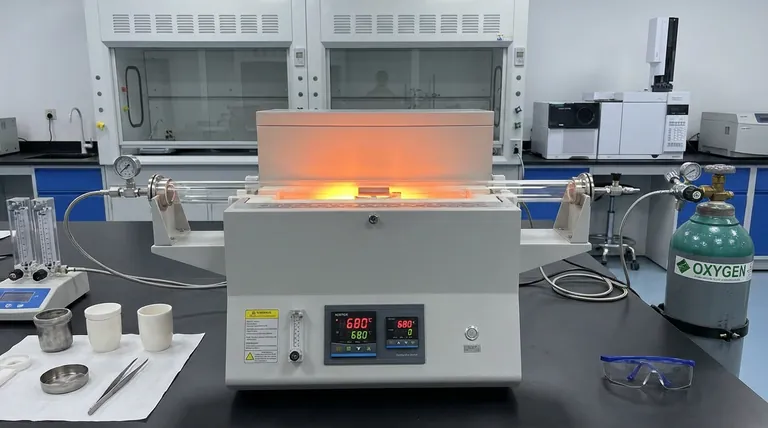

A bench-top high-temperature furnace guarantees ceramic layer quality by strictly enforcing specific thermal parameters and maintaining a stable oxidizing atmosphere. This equipment ensures the integrity of the Ceramic Conversion Treatment (CCT) on Ti6242 alloy by regulating heating and cooling rates to control oxygen diffusion and crystal growth.

The furnace’s primary role is to synchronize oxygen diffusion with crystal growth through strict temperature management, transforming the surface into a robust ceramic shield without compromising the substrate bond.

The Mechanics of Thermal Control

To understand how the furnace ensures quality, we must look at how it manages the environment surrounding the Ti6242 alloy.

Precision Temperature Regulation

The furnace maintains a critical temperature window between 640 °C and 700 °C.

Maintaining this range is essential for initiating the chemical conversion process without overheating the substrate.

Stable Oxidizing Atmosphere

Beyond temperature, the furnace provides a consistent supply of oxygen.

This stable atmosphere is required to feed the oxidation reaction necessary to convert the titanium surface into ceramic.

The Critical Role of Ramp Rates

The quality of the ceramic layer is defined by how the material transitions between temperature states. The furnace's programmable logic controls this via specific ramp rates.

Controlled Heating

The furnace applies a heating rate of 8 °C/min.

This controlled ascent prevents thermal shock and establishes the initial conditions for orderly diffusion of oxygen atoms into the alloy lattice.

Regulated Cooling

Perhaps the most critical phase is the cooling process, which the furnace restricts to 2 °C/min.

This slow descent allows for the stable growth of oxide crystals. It prevents the internal stress that often leads to cracking in ceramic materials.

Understanding the Trade-offs

While the high-temperature furnace provides necessary control, it is important to understand the risks if these parameters are not maintained.

The Risk of Rapid Cooling

If the furnace fails to maintain the strict 2 °C/min cooling rate, the ceramic layer may suffer.

Faster cooling can interrupt the crystal growth, leading to a porous structure rather than a dense titanium dioxide layer. It may also cause the coating to detach from the substrate.

The Impact of Temperature fluctuation

If the target temperature (640-700 °C) drifts, the diffusion of oxygen becomes unpredictable.

This results in uneven oxide thickness and a weak bond between the ceramic layer and the Ti6242 alloy.

Ensuring Process Integrity

To maximize the performance of your CCT process, ensure your equipment is calibrated to these specific constraints.

- If your primary focus is Layer Density: Ensure the furnace is programmed for a slow cooling rate of exactly 2 °C/min to promote stable crystal growth.

- If your primary focus is Substrate Adhesion: Verify that the heating rate does not exceed 8 °C/min to allow for the orderly diffusion of oxygen atoms.

Precision control of thermal rates is the difference between a brittle coating and a durable, integrated ceramic surface.

Summary Table:

| Process Parameter | Required Specification | Role in Quality Control |

|---|---|---|

| Temperature Range | 640 °C - 700 °C | Initiates chemical conversion without substrate damage |

| Heating Rate | 8 °C/min | Prevents thermal shock; ensures orderly oxygen diffusion |

| Cooling Rate | 2 °C/min | Promotes stable crystal growth; prevents cracking |

| Atmosphere | Stable Oxidizing | Sustains the reaction to form dense titanium dioxide |

Elevate Your Material Science with KINTEK Precision

Achieving the perfect ceramic conversion requires uncompromising thermal accuracy. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of lab research and industrial applications. Whether you are treating Ti6242 alloys or developing new ceramic layers, our customizable high-temperature furnaces deliver the stable atmospheres and precise ramp rates essential for your success.

Ready to optimize your heat treatment process? Contact us today to discuss your unique needs with our technical specialists.

References

- Zhenxue Zhang, Hanshan Dong. Tribological Properties of the Fast Ceramic Conversion Treated Ti-6Al-2Sn-4Zr-2Mo Alloy with a Pre-Deposited Gold Layer. DOI: 10.3390/lubricants12040105

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key factors to consider when buying a muffle furnace? Select the Right Furnace for Your Lab

- What factors affect the price range of muffle furnaces? Key Drivers for Smart Lab Investment

- What is the temperature range of a box furnace? Key Factors for Your Application

- How is a muffle furnace used in heat treatment processes? Achieve Precise Material Transformations

- What role does a high-temperature laboratory muffle furnace play in Indium-doped LLZO? Optimize Solid Electrolyte Synthesis

- What are the different types of heating elements used in muffle furnaces and their temperature ranges? Choose the Right Element for Your Lab

- What are the core functions of a laboratory muffle furnace in nickel-based catalyst optimization? Enhance Your Synthesis

- What role does a Muffle furnace play in chemical reactions? Achieve Precise, Contamination-Free Thermal Processing