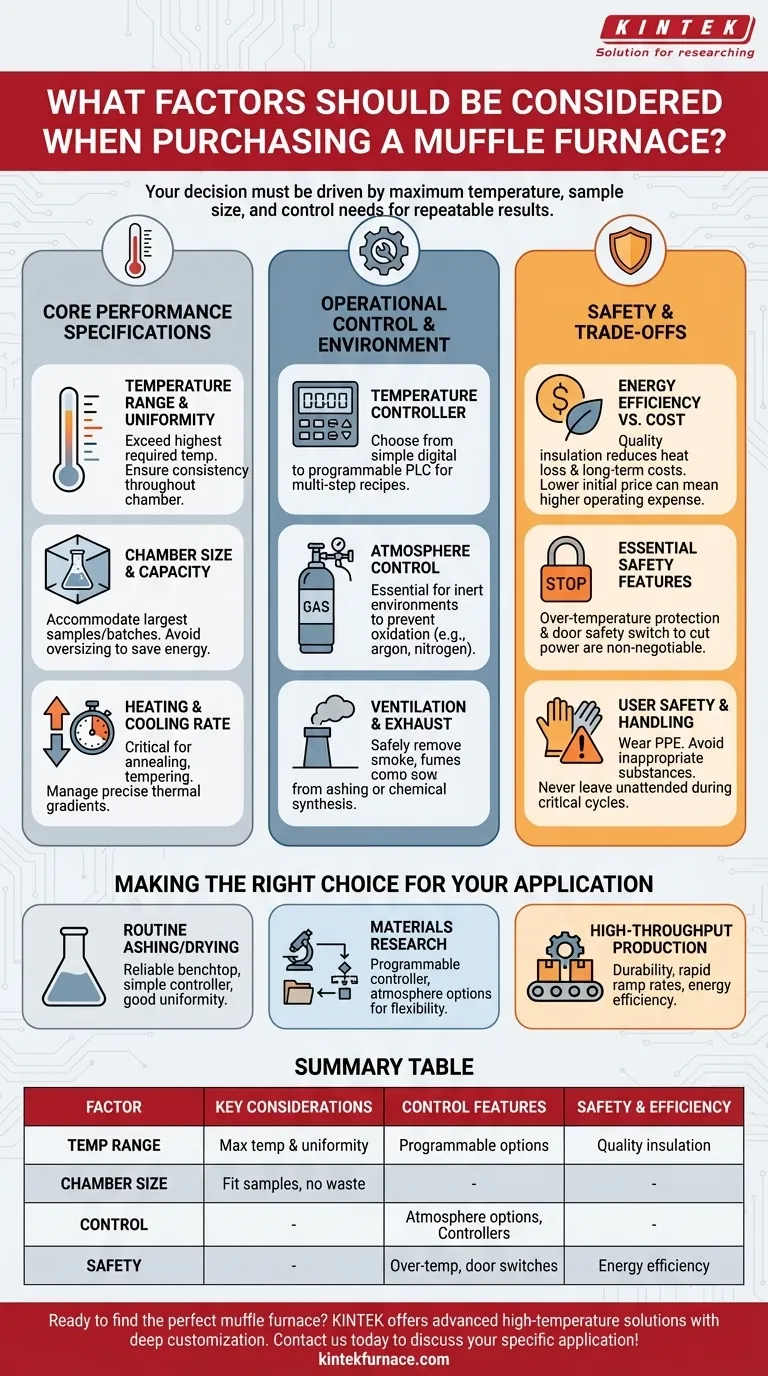

When purchasing a muffle furnace, your decision must be driven by three core factors: the maximum temperature your process requires, the size of your samples, and the level of atmospheric and temperature control needed for repeatable results. These technical requirements dictate every other choice, from heating element type to long-term operating cost.

A muffle furnace is not a simple oven; it is a precision instrument tailored to a specific scientific or industrial process. The goal is to invest in a furnace that perfectly matches the demands of your application, ensuring safety, accuracy, and efficiency for years to come.

Core Performance Specifications: Matching the Furnace to Your Process

The primary function of the furnace is to execute a thermal process reliably. Its core specifications must align perfectly with the demands of that process.

Temperature Range and Uniformity

The maximum achievable temperature is the most obvious specification, but it's not the only one that matters. Ensure the furnace's range comfortably exceeds your highest required temperature.

Equally important is temperature uniformity, which is the consistency of temperature throughout the entire chamber. Poor uniformity can lead to inconsistent results, especially when processing multiple samples at once.

Chamber Size and Capacity

Select a chamber that can accommodate the dimensions and volume of your largest samples or batches. However, avoid choosing an oversized furnace "just in case."

A larger chamber takes longer to heat up and consumes significantly more energy per cycle. The ideal size is one that meets your current and near-future needs without excessive waste.

Heating and Cooling Rate (Ramp Rate)

The speed at which the furnace can heat up (ramp rate) and cool down is a critical parameter for many processes like annealing, tempering, and ceramic firing.

If your work requires precise thermal gradients or multi-step profiles, you need a furnace and controller capable of managing these rates accurately.

Operational Control and Environment

Modern furnace operations go beyond simply holding a temperature. The ability to control the process and the atmosphere inside the chamber is essential for advanced applications.

Temperature Controller and Programming

Controllers range from simple digital models that maintain a single setpoint to advanced PLC-based programmable controllers.

A programmable controller allows you to create multi-step recipes involving different temperatures, ramp rates, and dwell times. This is non-negotiable for complex material science, metallurgy, or research applications.

Atmosphere Control

Many processes cannot be performed in ambient air. Atmosphere control is necessary for applications requiring an inert environment (using gases like argon or nitrogen) to prevent oxidation.

If this is a requirement, ensure the furnace is equipped with sealed gas ports for introducing and venting specific gases.

Ventilation and Exhaust

Processes like ashing, chemical synthesis, or binder burnout produce smoke, fumes, or vapors. These byproducts must be safely removed from the chamber and the laboratory.

A furnace intended for these applications must have a dedicated ventilation port or chimney to connect to an exhaust system.

Understanding the Trade-offs and Safety Imperatives

A furnace is a high-energy device that presents significant operational risks. Balancing cost with safety and efficiency is a critical part of the purchasing decision.

Energy Efficiency vs. Initial Cost

High-quality insulation (such as dense ceramic or alumina fiber) reduces heat loss, leading to lower energy consumption and more stable temperatures.

A furnace with a lower initial price may use inferior insulation, resulting in much higher long-term operating costs and a hotter external surface, which is also a safety hazard.

Essential Safety Features

Never compromise on safety. Key features include over-temperature protection, which automatically shuts down the furnace if it exceeds a maximum safe temperature.

A door safety switch that cuts power to the heating elements when the door is opened is another critical feature to prevent electrical shock and thermal exposure.

User Safety and Handling

The furnace's design must be supplemented with strict operational protocols. Always wear appropriate personal protective equipment (PPE), especially heat-resistant gloves.

Avoid placing liquids or volatile substances inside unless the furnace is specifically designed for that purpose. Never leave a furnace unattended during critical parts of a cycle.

Making the Right Choice for Your Application

Use your specific process requirements as a filter to evaluate potential models. This ensures you invest in a tool that is an asset, not a liability.

- If your primary focus is routine ashing or drying: A reliable benchtop furnace with a simple digital controller and good temperature uniformity is often sufficient.

- If your primary focus is materials research or process development: Prioritize a furnace with a programmable controller and options for atmosphere control to ensure maximum flexibility.

- If your primary focus is high-throughput production: Focus on durability, rapid ramp rates, and energy efficiency to minimize cycle time and long-term operating costs.

Ultimately, the right muffle furnace is the one that meets your technical needs with uncompromising safety and reliability.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | Maximum temperature and uniformity for consistent results |

| Chamber Size | Capacity to fit samples without energy waste |

| Control Features | Programmable controllers and atmosphere options for precision |

| Safety | Over-temperature protection and door switches for user safety |

| Energy Efficiency | Quality insulation to reduce long-term costs |

Ready to find the perfect muffle furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for enhanced safety, accuracy, and efficiency. Contact us today to discuss how our tailored solutions can benefit your specific application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation