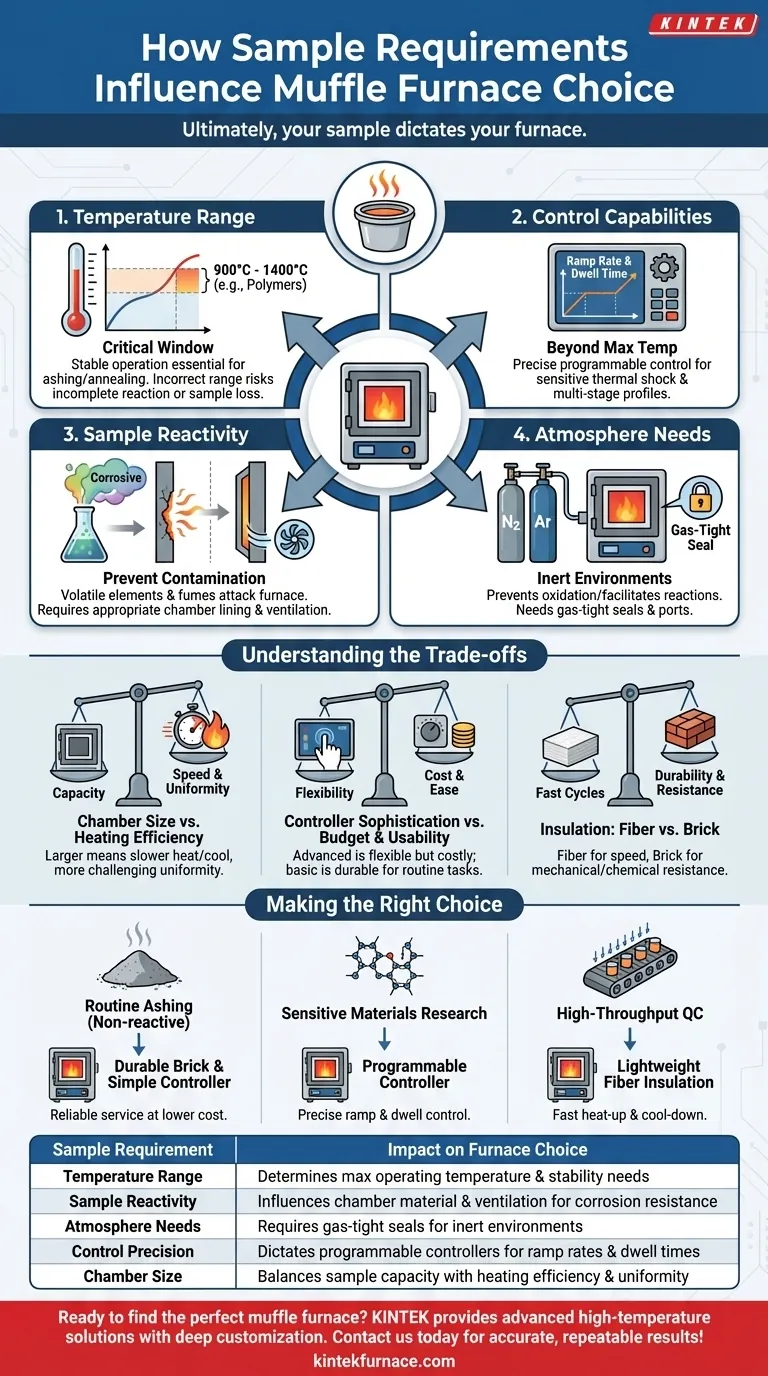

Ultimately, your sample dictates your furnace. The single most critical factor in selecting a muffle furnace is the chemical and physical nature of the material you intend to heat. Key sample requirements, such as the necessary temperature range and potential for releasing corrosive elements, directly determine the required performance, features, and construction of the furnace you need to ensure accurate and repeatable results.

The core decision is not just about finding a furnace that can reach a maximum temperature. It is about matching the furnace's precise control capabilities, chamber materials, and temperature uniformity to the specific requirements of your sample to guarantee the integrity of your process and data.

Matching Furnace Performance to Sample Demands

The primary function of a furnace is to provide a controlled thermal environment. How well it performs this function in relation to your specific sample is the foundation of a successful investment.

The Critical Role of Temperature Range

Every material has a specific temperature window required for processes like ashing, annealing, or heat-treating. Using a furnace that cannot operate stably within this window will compromise your results.

For example, many polymer compounds require a precise range, often between 900°C and 1400°C. Operating below this range may result in an incomplete reaction, while exceeding it can cause the sample to disintegrate or volatilize, leading to sample loss and unreliable data.

Beyond Max Temp: The Importance of Control

Simply reaching a target temperature is not enough. The way the furnace achieves and holds that temperature is equally vital for sensitive samples.

Advanced digital controllers allow you to manage ramp rates (how quickly the temperature rises) and dwell times (how long it holds at a specific temperature). This programmability is essential for materials that are sensitive to thermal shock or that require multi-stage heating profiles.

Considering Sample Composition and Reactivity

Your sample doesn't just sit passively in the furnace; it can interact with the chamber environment, creating secondary requirements for the equipment.

Preventing Sample and Furnace Contamination

During heating, some samples release volatile elements, acids, or fumes. These byproducts can attack the furnace's heating elements or insulation, leading to premature failure.

Furthermore, these residues can remain in the chamber and contaminate subsequent, different samples, invalidating future work. Choosing a furnace with the appropriate chamber lining and adequate ventilation is critical for managing these reactive samples.

Chamber Atmosphere Requirements

Many standard applications simply heat samples in ambient air. However, more advanced processes may require a modified atmosphere to prevent unwanted oxidation or to facilitate a specific chemical reaction.

If your sample requires heating in an inert environment (like nitrogen or argon), you will need a furnace specifically designed with gas-tight seals and ports for introducing and venting these gases.

Understanding the Trade-offs

Choosing a furnace involves balancing performance, features, and cost. Understanding the key trade-offs will help you make an objective decision.

Chamber Size vs. Heating Efficiency

A larger furnace chamber allows you to process more or bigger samples at once. However, a larger thermal mass means it will generally take longer to heat up and cool down, and achieving perfect temperature uniformity can be more challenging.

Controller Sophistication vs. Budget and Usability

A furnace with a multi-stage, programmable controller offers immense process flexibility. However, this capability comes at a higher cost and may be unnecessary for simple, single-temperature applications. A basic controller is often more durable and easier to operate for routine tasks.

Insulation: Fiber vs. Brick

Modern furnaces typically use lightweight ceramic fiber insulation, which allows for very rapid heat-up and cool-down cycles. Traditional hard firebrick insulation is heavier and slower to heat but is often more resistant to mechanical wear and certain chemical fumes. The right choice depends on your need for speed versus durability.

Making the Right Choice for Your Application

Use your sample's specific needs as your guide to filter your options and select the appropriate tool for the job.

- If your primary focus is routine ashing of non-reactive samples: A durable, brick-lined furnace with a simple digital controller will provide reliable service at a lower cost.

- If your primary focus is research on sensitive materials like polymers: Prioritize a furnace with a sophisticated, programmable controller for precise ramp and dwell control.

- If your primary focus is high-throughput quality control: A furnace with lightweight fiber insulation will deliver the fast heat-up and cool-down cycles needed to maximize productivity.

By first defining your sample's requirements, you can confidently select a muffle furnace that serves as a reliable instrument rather than a source of experimental error.

Summary Table:

| Sample Requirement | Impact on Furnace Choice |

|---|---|

| Temperature Range | Determines max operating temperature and stability needs |

| Sample Reactivity | Influences chamber material and ventilation for corrosion resistance |

| Atmosphere Needs | Requires gas-tight seals for inert environments |

| Control Precision | Dictates programmable controllers for ramp rates and dwell times |

| Chamber Size | Balances sample capacity with heating efficiency and uniformity |

Ready to find the perfect muffle furnace for your unique sample needs? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your experimental requirements. Contact us today to ensure accurate, repeatable results and enhance your lab's efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation