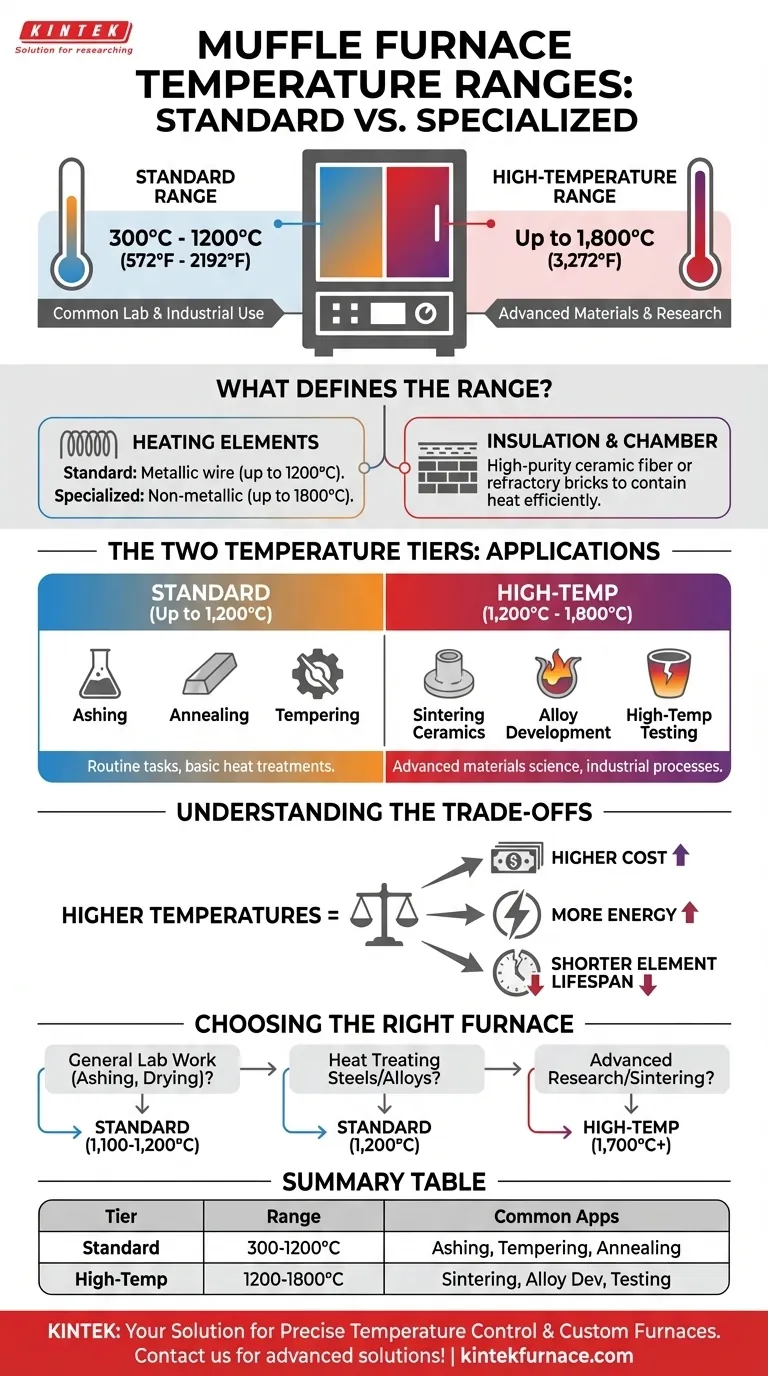

In most cases, a standard muffle furnace operates within a temperature range of approximately 300°C to 1,200°C (572°F to 2,192°F). This range is suitable for a wide variety of common laboratory and industrial processes, including ashing, tempering, and basic heat treatments. However, specialized models designed for more demanding applications can achieve significantly higher temperatures, often reaching up to 1,800°C (3,272°F).

The "standard" temperature range provides a useful baseline, but the critical factor is matching the furnace's maximum temperature to the precise demands of your specific process. Understanding what defines this capability is key to selecting the right tool.

What Defines a Furnace's Temperature Range?

A muffle furnace's performance is not arbitrary; it is the direct result of its core components. The maximum achievable temperature is determined by the physical limitations of its heating elements and insulation.

The Role of Heating Elements

The heart of the furnace is its heating element, and the material it is made from dictates the upper temperature limit.

Standard furnaces typically use robust metallic wire elements that perform reliably up to about 1,200°C. To exceed this, specialized, non-metallic elements are required, which can withstand the extreme thermal stress of operating at temperatures up to 1,800°C.

The Importance of Insulation and Chamber Material

High temperatures must be safely and efficiently contained. The furnace chamber is lined with advanced insulation, usually high-purity ceramic fiber or refractory bricks.

These materials prevent heat loss, allowing the furnace to maintain a stable and uniform temperature while keeping the exterior shell cool and safe to the touch. The quality of this insulation is just as critical as the heating elements for high-temperature performance.

The Different Temperature Tiers

Not all muffle furnaces are created equal. They can be broadly categorized into two tiers based on their temperature capabilities and intended use.

Standard Range (Up to 1,200°C)

This is the workhorse category for most laboratories and workshops. These furnaces are ideal for routine applications that do not require extreme heat.

Common uses include ashing organic materials to determine inorganic content, annealing metals to soften them, and tempering steel to increase its toughness.

High-Temperature Range (1,200°C to 1,800°C)

These are specialized instruments built for advanced materials science and industrial processes. Reaching these temperatures requires specialized heating elements and more robust insulation.

Typical applications include sintering advanced ceramics, developing new alloys, melting certain types of glass, or conducting high-temperature materials testing.

Understanding the Trade-offs

Choosing a furnace is not simply about getting the highest temperature possible. There are critical trade-offs to consider that impact cost, efficiency, and equipment longevity.

Cost vs. Capability

There is a significant price increase when moving from a standard 1,200°C furnace to a 1,800°C model. The specialized materials required for high-temperature elements and insulation are substantially more expensive to manufacture and install.

Energy Consumption

Higher temperatures require exponentially more energy to achieve and maintain. A furnace running at 1,700°C will consume significantly more power than one operating at 900°C, leading to higher operational costs.

Lifespan of Heating Elements

Heating elements are consumable components that degrade over time, especially when operated near their maximum rated temperature. Consistently running a furnace at its upper limit will shorten element lifespan and increase maintenance frequency compared to operating it comfortably within its mid-range.

Choosing the Right Furnace for Your Application

The right choice depends entirely on the requirements of your specific task. Over-specifying a furnace leads to unnecessary expense, while under-specifying it makes your intended process impossible.

- If your primary focus is general lab work like ashing or drying: A standard furnace with a maximum temperature of 1,100°C or 1,200°C is more than sufficient and cost-effective.

- If your primary focus is heat treating common steels or alloys: A furnace reaching 1,200°C will cover most basic tempering and annealing processes effectively.

- If your primary focus is advanced materials research or sintering ceramics: You must select a high-temperature model specifically rated to achieve 1,700°C, 1,800°C, or higher.

Ultimately, selecting the correct muffle furnace is an investment in procedural accuracy and operational efficiency.

Summary Table:

| Temperature Tier | Typical Range | Common Applications |

|---|---|---|

| Standard Range | 300°C to 1,200°C | Ashing, tempering, annealing, basic heat treatments |

| High-Temperature Range | 1,200°C to 1,800°C | Sintering ceramics, alloy development, high-temperature testing |

Ensure precise temperature control for your experiments with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique needs. Contact us today to discuss how our solutions can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis