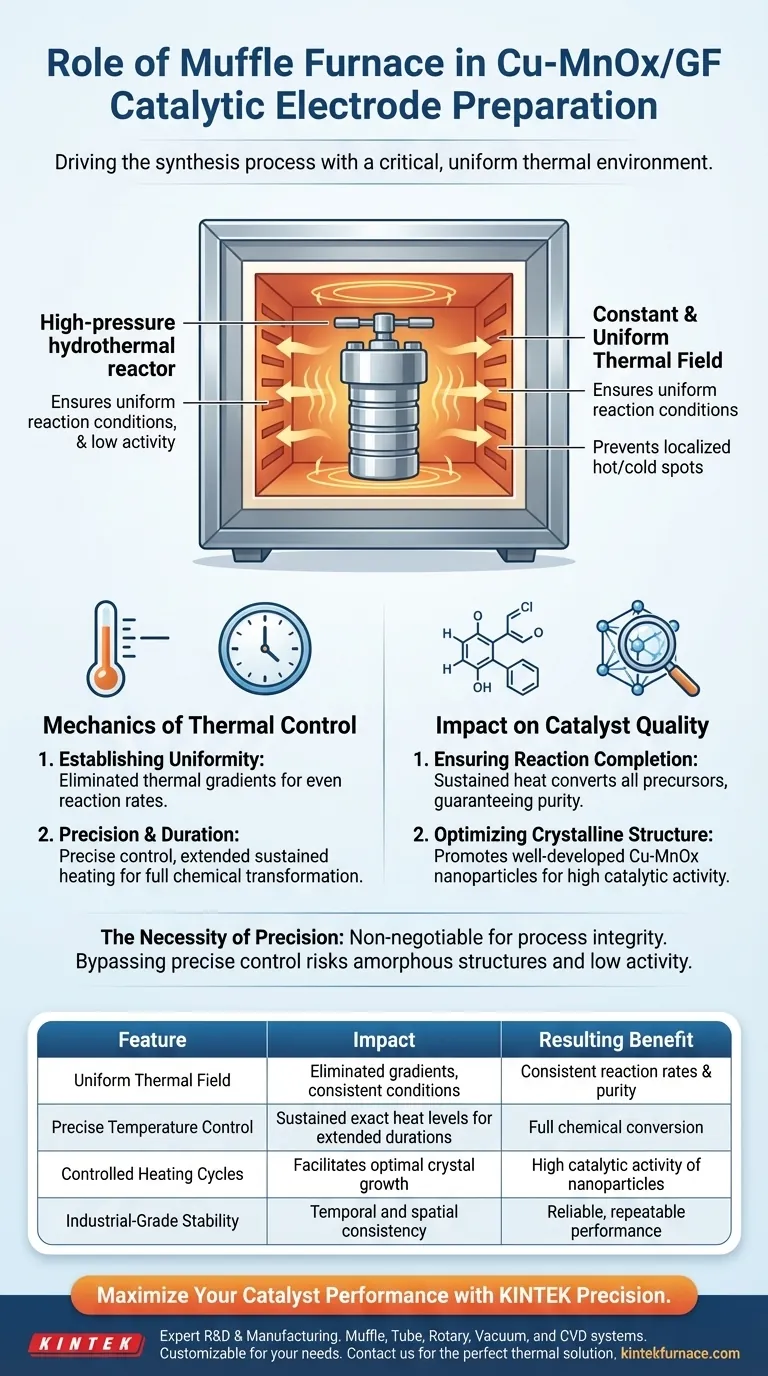

In the preparation of Cu-MnOx/GF catalytic electrodes, the muffle furnace serves as the critical thermal environment that drives the synthesis process. It houses the high-pressure hydrothermal reactor, providing a constant and uniform thermal field that allows the necessary chemical reactions to proceed effectively.

By maintaining precise temperature control over extended periods, the muffle furnace ensures the formation of well-developed crystalline nanoparticles, which is the defining factor for the electrode's high catalytic activity.

The Mechanics of Thermal Control

Establishing a Uniform Environment

The primary function of the industrial-grade muffle furnace is to eliminate thermal gradients. It creates a constant and uniform thermal field around the high-pressure hydrothermal reactor placed inside it.

This uniformity ensures that the entire sample experiences the exact same conditions. It prevents localized hot or cold spots that could lead to uneven reaction rates within the reactor.

Precision and Duration

Beyond spatial uniformity, the furnace is responsible for temporal consistency. It utilizes a precise temperature control system to maintain specific heat levels without fluctuation.

The furnace maintains this continuous heating for extended periods. This sustained energy input is required to drive the chemical transformation fully, ensuring the process does not stall prematurely.

Impact on Catalyst Quality

Ensuring Reaction Completion

The controlled heating process is not merely about reaching a temperature; it is about sustaining it long enough for the chemistry to resolve. The muffle furnace ensures that the chemical reactions involved in the synthesis proceed to completion.

If the heating were intermittent or uneven, the precursors might not fully convert. This would leave unreacted materials in the final product, compromising the electrode's purity and function.

Optimizing Crystalline Structure

The ultimate goal of this thermal treatment is the structural development of the material. The stable environment allows for the growth of well-developed crystalline Cu-MnOx nanoparticles.

High-quality crystallinity is directly linked to performance. It is this specific crystalline structure that endows the Cu-MnOx/GF electrodes with their high catalytic activity.

The Necessity of Precision

While the muffle furnace is a standard tool, its role here is non-negotiable regarding process integrity. The "trade-off" in this context is binary: there is no shortcut to achieving high activity.

Attempting to bypass the precise control of a muffle furnace risks producing amorphous or poorly formed structures. Without the rigorous thermal regulation provided by the furnace, you cannot guarantee the high catalytic activity required for the electrode to function effectively.

Making the Right Choice for Your Goal

When setting up your synthesis protocol for Cu-MnOx/GF electrodes, consider the following focus areas:

- If your primary focus is Catalytic Performance: Prioritize the precision of the furnace's temperature control system to ensure maximum crystallinity of the nanoparticles.

- If your primary focus is Process Consistency: Focus on the furnace's ability to maintain a uniform thermal field over extended durations to guarantee reaction completion every time.

The muffle furnace is not just a heater; it is the architect of the nanoparticle structure that defines your electrode's success.

Summary Table:

| Feature of Muffle Furnace | Impact on Cu-MnOx/GF Preparation | Resulting Benefit |

|---|---|---|

| Uniform Thermal Field | Eliminates thermal gradients around the reactor | Consistent reaction rates and material purity |

| Precise Temperature Control | Sustains exact heat levels for extended durations | Full chemical conversion of precursors |

| Controlled Heating Cycles | Facilitates optimal crystal growth | High catalytic activity of nanoparticles |

| Industrial-Grade Stability | Ensures temporal and spatial consistency | Reliable and repeatable electrode performance |

Maximize Your Catalyst Performance with KINTEK Precision

Precision thermal processing is the foundation of high-activity Cu-MnOx/GF electrodes. At KINTEK, we understand that even minor temperature fluctuations can compromise your crystalline structures. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific research or production needs.

Whether you are focusing on maximizing nanoparticle crystallinity or ensuring process consistency, our high-temperature lab furnaces provide the reliability you need to succeed. Contact us today to find the perfect thermal solution for your lab.

Visual Guide

References

- H Liu, Y. Mao. Electrocatalytic Oxidation for Efficient Toluene Removal with a Catalytic Cu-MnOx/GF Electrode in a Solid-State Electrocatalytic Device. DOI: 10.3390/catal15080749

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

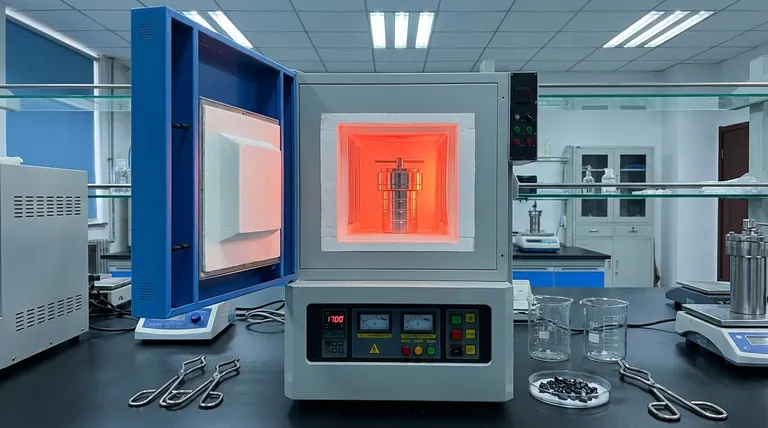

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between a muffle furnace and an oven? A Guide to High-Temperature Processing Purity

- What factors affect the price of muffle furnaces? Key Drivers for Smart Lab Investment

- What role does a muffle furnace play in the post-treatment of cobalt-based catalysts? Optimize Phase Purity via Annealing

- What are the main industrial applications of muffle furnaces? Precision Heating for Analysis and Synthesis

- What is the role of an industrial-grade high-temperature box furnace in Ni-Ti-Hf-La alloy post-processing?

- What safety feature is included in muffle furnaces to protect operators? Essential Safeguards for Lab Safety

- What precautions should be taken when opening a muffle furnace after use? Essential Safety Steps for Lab Protection

- Why are box furnaces considered essential in various industries? Discover Their Versatile Heating Solutions