At their core, muffle furnaces are instruments of precise thermal transformation and analysis. They are used across a vast range of industries for applications that require high heat in a controlled, contaminant-free environment. Key applications include material analysis (like determining ash content), heat-treating metals like steel, sintering ceramics, and preparing samples in biomedical and research labs.

The true value of a muffle furnace is not just its ability to generate high temperatures, but its design that isolates the sample from the heating elements. This "muffle" prevents contamination, which is the critical requirement that unites its diverse applications, from chemical analysis to high-purity material treatment.

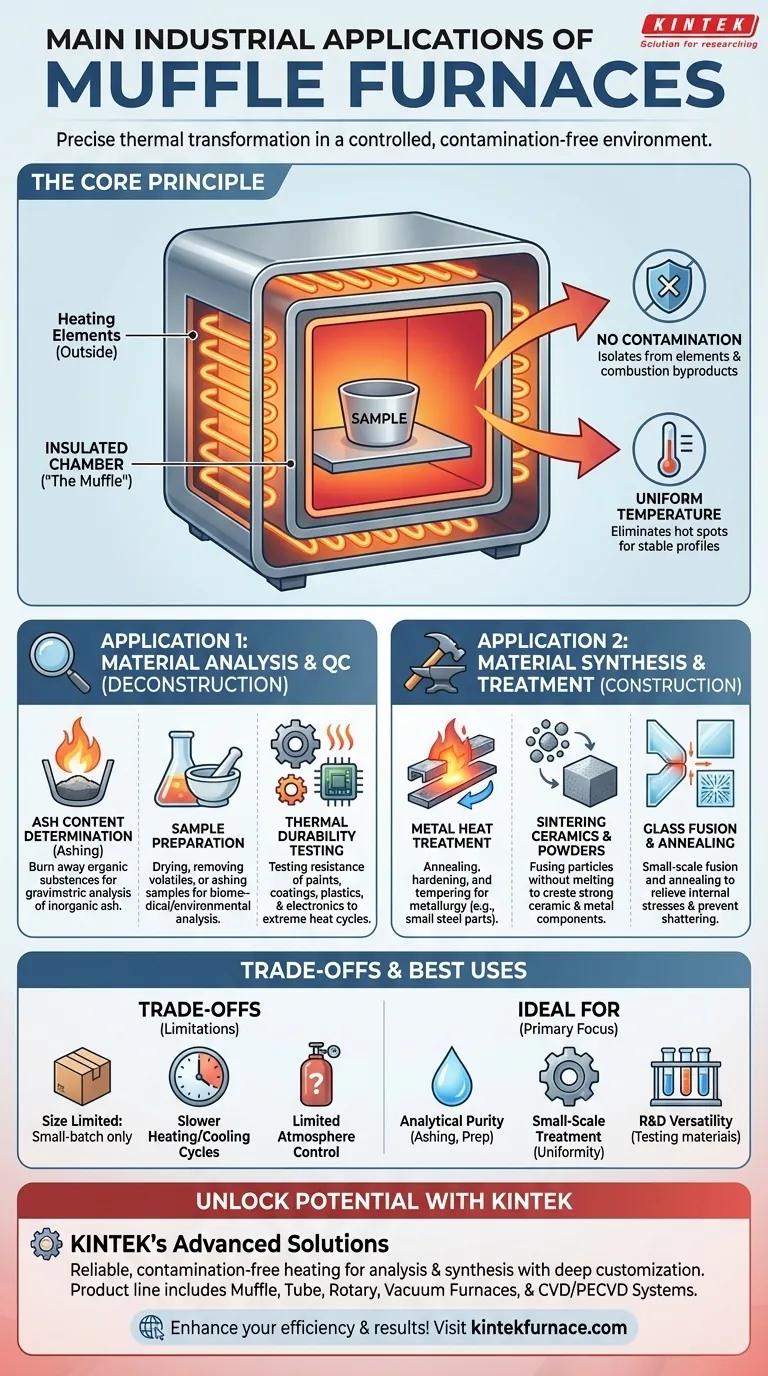

The Principle: Why Isolation is Key

Before listing the applications, it is essential to understand the core principle that makes a muffle furnace so versatile. The name itself reveals its function.

What is a "Muffle"?

A muffle is an insulated internal chamber that contains the material being heated. The heating elements are on the outside of this chamber.

This design separates the sample from direct exposure to the flame or electrical elements that generate the heat. The chamber walls heat up and radiate that energy evenly throughout the interior.

Preventing Contamination

For many processes, any impurity can ruin the result. The muffle ensures that byproducts of combustion or particles from the heating elements do not contact and contaminate the sample.

This is non-negotiable in analytical chemistry, pharmaceutical research, and aerospace material science, where purity is paramount.

Ensuring Temperature Uniformity

The insulated chamber design allows for exceptionally stable and uniform temperatures. By heating the entire chamber, it eliminates hot spots that could occur with direct heating, ensuring the entire sample experiences the same thermal profile.

Core Application 1: Material Analysis and Quality Control

The most common use for a muffle furnace is to find out what a material is made of or how it behaves under thermal stress. This is a process of deconstruction.

Ash Content Determination (Ashing)

This is a foundational technique in analytical chemistry. A sample (like coal, oil, food, plastic, or rubber) is heated to a high temperature to completely burn away all organic substances.

The weight of the remaining inorganic residue, or ash, is then measured. This process, known as gravimetric analysis, is a critical quality control step in countless industries.

Sample Preparation

In many biomedical and environmental labs, samples must be prepared before they can be analyzed by more advanced equipment.

A muffle furnace can be used to dry samples, remove volatile compounds, or reduce a substance to a simple ash for subsequent elemental analysis.

Thermal Durability Testing

Engineers need to know how their materials will perform under extreme conditions. Muffle furnaces are used to test the heat resistance of paints, coatings, plastics, and electronic components.

By subjecting materials to controlled high-temperature cycles, manufacturers can verify their durability and safety specifications.

Core Application 2: Material Synthesis and Treatment

The other major function of a muffle furnace is to use heat to change a material's physical properties or combine elements to create something new. This is a process of construction.

Metal Heat Treatment

Processes like annealing, hardening, and tempering are fundamental in metallurgy.

Annealing involves heating a metal and cooling it slowly to make it softer and more workable. The uniform heat of a muffle furnace is ideal for treating small steel or metal parts without contamination.

Sintering Ceramics and Powders

Sintering is a process that uses heat to fuse particles together without melting them. This is how many ceramic components, as well as parts made from powdered metals, are created.

The precise temperature control of a muffle furnace allows for strong, dense final products with predictable properties.

Glass Fusion and Annealing

In glass manufacturing, a muffle furnace can be used for smaller-scale fusion processes. More importantly, it is used for annealing glass to relieve internal stresses created during its formation, which prevents it from shattering.

Understanding the Trade-offs

While incredibly useful, muffle furnaces are not the solution for every heating application. Understanding their limitations is key to using them effectively.

Size and Throughput Limitations

Muffle furnaces are typically designed for laboratory-scale or small-batch production. They are not suited for processing large volumes or massive industrial workpieces, which require larger, more specialized furnaces.

Slower Heating and Cooling Cycles

The same insulation that provides excellent temperature stability also means that muffle furnaces take longer to heat up and cool down compared to direct-fired furnaces. This can be a drawback in high-throughput environments.

Atmosphere Control

While some advanced muffle furnaces allow for the introduction of inert gases, they do not offer the sophisticated atmosphere control of dedicated vacuum or controlled-atmosphere furnaces. For materials highly sensitive to oxygen, a different tool may be required.

Making the Right Choice for Your Application

Ultimately, the decision to use a muffle furnace depends on your primary goal.

- If your primary focus is analytical purity: The muffle furnace is the definitive tool for ashing and sample preparation where preventing contamination is the most important factor.

- If your primary focus is small-scale material treatment: It provides excellent temperature uniformity for processes like annealing metals or sintering small ceramic parts with high precision.

- If your primary focus is research and development: Its versatility makes it a cornerstone laboratory instrument for testing how a wide variety of materials respond to controlled high temperatures.

Understanding these core functions allows you to leverage the muffle furnace as a precise tool for either controlled analysis or material creation.

Summary Table:

| Application Area | Key Uses | Benefits |

|---|---|---|

| Material Analysis | Ash content determination, sample preparation, thermal durability testing | Contamination-free, precise temperature control |

| Material Synthesis | Metal heat treatment (annealing, hardening), sintering ceramics, glass fusion | Uniform heating, high purity, versatile for small-scale production |

| Research & Development | Testing material responses, biomedical and environmental sample prep | Isolated chamber, reliable for diverse experiments |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable, contamination-free heating for material analysis, synthesis, and more. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization to precisely meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing