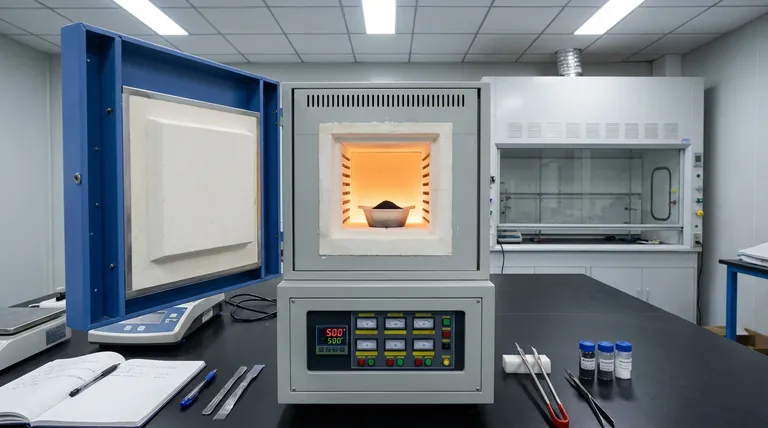

A muffle furnace serves as a critical structural stabilizer in the post-treatment of cobalt-based catalysts. It provides a static, controlled thermal environment that allows synthesized nanopowders to undergo precise annealing, transforming a raw, rapidly formed material into a refined catalyst.

Flame spray pyrolysis creates materials incredibly fast, often leaving behind unstable byproducts. The muffle furnace solves this by applying uniform heat to eliminate secondary phases like CoO or MnO2, ensuring the final product possesses a high-purity spinel crystal structure.

Achieving Structural Integrity

The primary function of the muffle furnace in this context is to correct the chaotic results of rapid synthesis.

Counteracting Rapid Synthesis

Flame spray pyrolysis is a high-energy, rapid process. While efficient, it often freezes the material in a non-equilibrium state before the crystal structure is fully settled.

The Role of Static Annealing

The muffle furnace provides a static thermal environment. By holding the material at specific temperatures—such as 500 °C for four hours—it gives the atomic structure the energy and time required to reorganize into a more stable configuration.

Enhancing Phase Purity

Beyond basic stabilization, the furnace is essential for chemical refinement.

Eliminating Secondary Phases

Raw FSP powders frequently contain unwanted secondary phases, specifically CoO (Cobalt Oxide) or MnO2 (Manganese Dioxide). These impurities can hinder the performance of the final catalyst.

Promoting the Spinel Structure

Through precise annealing, the furnace effectively reduces or eliminates these secondary phases. This thermal treatment drives the conversion of the material into a spinel structure, which is characterized by significantly higher phase purity and better catalytic potential.

Uniform Heating

Drawing on general material synthesis principles, muffle furnaces are designed to provide uniform heating. This ensures that the entire batch of nanopowder receives the same thermal treatment, preventing inconsistent results across the sample.

Understanding the Process Trade-offs

While necessary for quality, this step introduces specific constraints to the manufacturing workflow.

Batch vs. Continuous Processing

Flame spray pyrolysis is a continuous synthesis method, but muffle furnace treatment is inherently a batch process. This introduces a bottleneck where continuous output must be stopped and treated statically for hours.

Precision is Mandatory

The benefits of the muffle furnace are entirely dependent on strict parameter control. Deviating from the optimal temperature (e.g., 500 °C) or duration (e.g., 4 hours) may fail to eliminate the secondary phases or could alter the material properties undesirably.

Making the Right Choice for Your Goal

Using a muffle furnace is a strategic decision to prioritize material quality over processing speed.

- If your primary focus is Phase Purity: Utilize the furnace to strictly anneal the material at 500 °C, ensuring the total elimination of CoO and MnO2 byproducts.

- If your primary focus is Process Efficiency: Acknowledge that this static post-treatment step will interrupt continuous production flow, but is necessary to stabilize the crystal structure.

The muffle furnace effectively bridges the gap between rapid synthesis and reliable performance, converting raw nanopowders into stable, high-purity catalysts.

Summary Table:

| Process Feature | Role of Muffle Furnace | Impact on Catalyst |

|---|---|---|

| Structural Stability | Provides static annealing environment | Corrects non-equilibrium states from rapid FSP |

| Phase Purity | Eliminates CoO and MnO2 secondary phases | Promotes formation of high-purity spinel structure |

| Heating Consistency | Delivers uniform thermal distribution | Ensures batch-wide consistency in nanopowders |

| Optimal Parameters | Precise control (e.g., 500 °C for 4 hours) | Prevents undesirable material property alterations |

Elevate Your Material Research with KINTEK Precision

Transitioning from rapid synthesis to stable, high-performance catalysts requires uncompromising thermal control. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnaces designed to deliver the precise annealing environments necessary for phase purity and structural integrity.

Backed by expert R&D and advanced manufacturing, our systems are fully customizable to meet the unique demands of your laboratory or industrial workflow. Don't let processing bottlenecks compromise your results—leverage our expertise to optimize your catalyst post-treatment.

Contact KINTEK Experts Today to find the perfect high-temperature solution for your needs.

References

- Jinzhen Huang, Emiliana Fabbri. Surface oxidation/spin state determines oxygen evolution reaction activity of cobalt-based catalysts in acidic environment. DOI: 10.1038/s41467-024-47409-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the operating temperature ranges for different types of muffle furnaces? Find Your Ideal High-Temp Solution

- What are the main industries that use muffle furnaces? Essential for Clean Heat in Labs and Manufacturing

- Why is application important when selecting a muffle furnace? Ensure Optimal Performance for Your Lab

- What is the primary function of a muffle furnace in birnessite preparation? Optimize High-Temp Calcination Control

- What is the function of a laboratory high-temperature muffle furnace in niobate phosphor synthesis?

- What should be done before using a muffle furnace for the first time or after long inactivity? Essential Pre-Baking Guide

- How should the thermometer indicator be adjusted before using a muffle furnace? Ensure Accurate Temperature Readings

- What are the primary applications of a Muffle furnace in material treatment? Achieve Clean, High-Temperature Processing