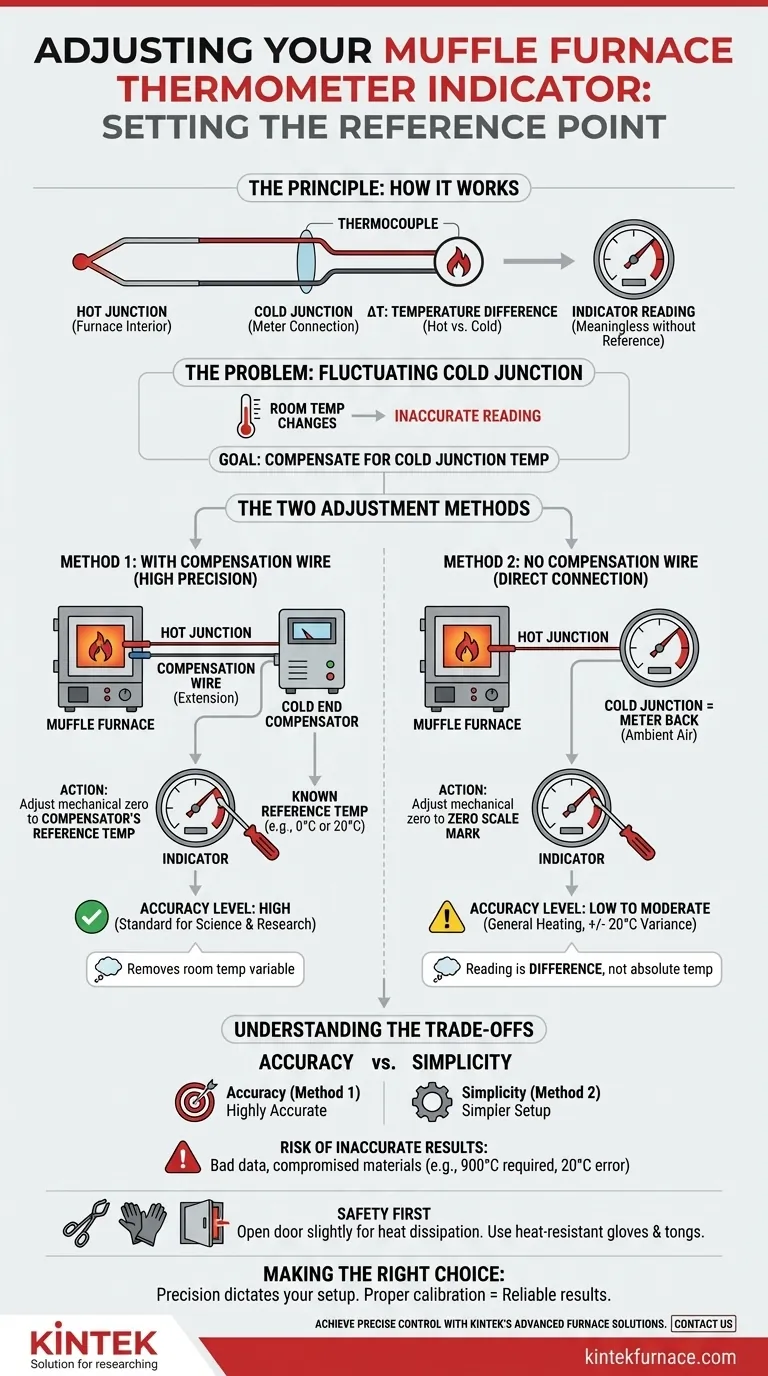

Before using a muffle furnace, the adjustment of the thermometer indicator depends entirely on your setup. If you are using a compensation wire and a cold end compensator, you must adjust the mechanical zero to the reference temperature of that compensator. If you are not using a compensation wire, the indicator's mechanical zero should be set to the zero scale mark.

The core task is not simply "zeroing" the indicator; it is establishing an accurate reference point. This ensures the reading reflects the true furnace temperature, not just the temperature difference between the furnace and the room.

The Principle: How a Furnace Thermometer Works

To adjust the indicator correctly, you must first understand the component that measures the heat: the thermocouple.

What a Thermocouple Measures

A thermocouple does not measure an absolute temperature. It works by measuring the temperature difference between two points: the hot junction (the probe tip inside the furnace) and the cold junction (where the thermocouple wires connect to the meter).

The voltage it generates is directly proportional to this difference. Therefore, the reading on your indicator is meaningless without knowing the temperature at the cold junction.

The Problem of the "Cold Junction"

The cold junction's location is the entire reason for the different adjustment procedures. If its temperature changes—for example, as the room heats up—your furnace reading will become inaccurate even if the furnace temperature itself is stable.

The goal of the adjustment is to compensate for the temperature at this cold junction.

The Two Methods for Indicator Adjustment

Your approach depends on whether you are actively managing the cold junction temperature with specialized wiring.

Method 1: Using a Compensation Wire

This is the most accurate and professionally preferred method. A compensation wire is a special extension cable that effectively moves the cold junction from the back of the hot furnace to a device called a cold end compensator.

This compensator maintains a known, stable reference temperature. In this case, you adjust the indicator's mechanical zero to match this known reference temperature. This tells the system its starting point, ensuring the final reading is highly accurate.

Method 2: No Compensation Wire (Direct Connection)

This simpler method connects the thermocouple directly to the indicator terminals. Here, the cold junction is simply the back of the meter itself, exposed to the ambient air of the lab.

When you set the mechanical zero to the zero scale mark, you are telling the meter to assume the cold junction is at 0°C. Since the room is never actually 0°C, the indicator will only show the difference between the furnace and the room. To get a true reading, you would theoretically need to add the current room temperature to the displayed temperature.

Understanding the Trade-offs

Choosing a method involves a direct trade-off between precision and convenience.

Accuracy vs. Simplicity

The method using a compensation wire is far more accurate because it removes the variable of fluctuating room temperature from the measurement. It is the standard for scientific research and controlled industrial processes.

The direct connection method is simpler to set up but is inherently less accurate. A 5°C change in room temperature will cause a 5°C error in your furnace reading.

The Risk of Inaccurate Results

Failing to set the reference point correctly leads to bad data. If a process requires a material to be treated at exactly 900°C, but your uncompensated reading is off by 20°C due to room temperature, your experimental outcome or material properties will be compromised.

A Note on Safe Operation

Regardless of measurement accuracy, always prioritize safety. When placing or removing samples, open the furnace door slightly to allow initial heat to dissipate. Always use appropriate tongs and heat-resistant gloves, handling items carefully to prevent severe burns.

Making the Right Choice for Your Goal

Your required level of precision should dictate your setup.

- If your primary focus is high-precision scientific results: You must use a compensation wire and cold junction compensator, setting the indicator to the compensator's reference temperature.

- If your primary focus is general heating where a +/- 20°C variance is acceptable: A direct connection may suffice, but you must remain aware that the displayed value is relative and not an absolute temperature.

Properly calibrating your furnace's temperature indicator is the foundation of reliable and repeatable high-temperature work.

Summary Table:

| Adjustment Method | When to Use | Key Action | Accuracy Level |

|---|---|---|---|

| With Compensation Wire | High-precision scientific work | Set mechanical zero to compensator's reference temperature | High |

| Without Compensation Wire | General heating with acceptable variance | Set mechanical zero to zero scale mark | Low to Moderate |

Achieve precise temperature control in your lab with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your research and ensure reliable results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating