Before its first use or after a long period of inactivity, a muffle furnace must undergo a critical pre-baking or drying procedure. This process involves slowly heating the furnace through a specific temperature range for several hours. This is not an optional step; it is essential for preventing catastrophic damage to the furnace's internal components.

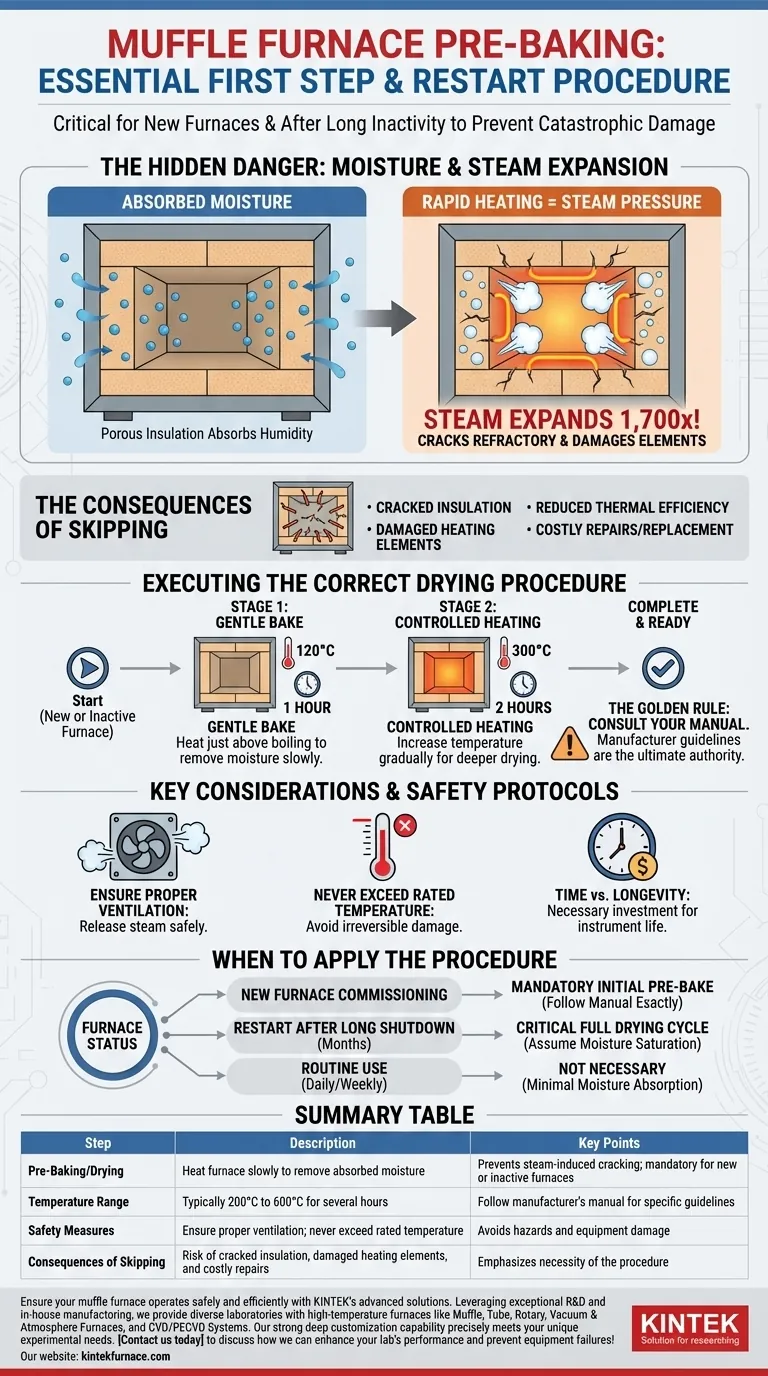

The porous ceramic insulation inside a muffle furnace absorbs moisture from the air over time. Rapidly heating a damp furnace turns this trapped moisture into high-pressure steam, which can crack the refractory lining and damage the heating elements. A controlled drying cycle is the only way to safely remove this moisture and protect the equipment.

Why Pre-Baking is Non-Negotiable

Understanding the science behind this procedure clarifies why it is a mandatory step for ensuring the furnace's longevity and safety. The risk lies in the physical properties of the furnace's core materials.

The Hidden Danger: Absorbed Moisture

The refractory bricks and ceramic fiber insulation that line a muffle furnace are, by nature, porous. Like a sponge, these materials slowly absorb and hold water molecules from the ambient humidity in the air. A furnace that has been sitting idle for weeks or months can hold a significant amount of moisture.

The Physics of Steam Expansion

When water turns to steam, it expands to over 1,700 times its original volume. If this phase change happens rapidly inside the microscopic pores of the ceramic material, the resulting internal pressure is immense. This process is often referred to as spalling.

This sudden, violent expansion exerts incredible force on the surrounding material, creating micro-fractures that can quickly propagate.

The Cost of Skipping This Step

Failing to perform a drying cycle can lead to severe and expensive consequences. The most common outcome is cracked insulation, which compromises the furnace's thermal efficiency and temperature uniformity.

In more extreme cases, the pressure can cause the refractory lining to shatter, permanently damaging the furnace chamber and potentially destroying the fragile heating elements. This turns a simple preventative measure into a costly repair or replacement.

Executing the Correct Drying Procedure

While the exact parameters depend on your specific model, the drying process follows a universal principle: raise the temperature slowly to allow moisture to evaporate and escape safely.

General Guideline: A Two-Stage Bake

A common and effective procedure involves a multi-hour bake at low to medium temperatures. One general recommendation is to heat the furnace for four hours at a temperature between 200°C and 600°C.

Another approach involves a two-stage process: first at a temperature just above boiling (e.g., 120°C for one hour), followed by a longer bake at a higher temperature (e.g., 300°C for two hours).

The Golden Rule: Consult Your Manual

The guidelines above are general examples. The manufacturer's manual for your specific furnace is the ultimate authority. Different models use different refractory materials and have unique thermal properties. Always follow the prescribed drying cycle from the manufacturer to guarantee safety and warranty compliance.

Understanding the Key Considerations

Executing this process correctly involves more than just setting a temperature. It requires acknowledging the trade-offs and adhering to critical safety protocols.

Time vs. Equipment Longevity

A drying cycle takes several hours and consumes energy. This is a necessary investment. Attempting to save a few hours by skipping this step puts the entire instrument, which can cost thousands of dollars, at risk.

Never Exceed the Rated Temperature

During the drying cycle, or any operation, do not exceed the maximum rated temperature of the furnace. This can cause irreversible damage to the heating elements and other components, creating both a functional and a fire hazard.

Ensure Proper Ventilation

The pre-baking process will release a noticeable amount of water vapor (steam) into the room. Ensure the area is well-ventilated to prevent a buildup of humidity and maintain a safe working environment.

How to Apply This to Your Furnace

Your approach should be based on the furnace's recent usage history.

- If your primary focus is commissioning a brand new furnace: You must perform the initial pre-baking cycle exactly as detailed in the manufacturer's manual to properly cure the materials and set the foundation for its operational life.

- If your primary focus is restarting a furnace after a long shutdown (months): Assume it is saturated with moisture and perform a full drying cycle as a critical preventative maintenance step.

- If your primary focus is routine use (daily or weekly): A full drying cycle is not necessary for frequent operation, as the furnace does not have time to absorb significant moisture between uses.

Properly conditioning your muffle furnace before use is the single most important step you can take to ensure its safety, accuracy, and longevity.

Summary Table:

| Step | Description | Key Points |

|---|---|---|

| Pre-Baking/Drying | Heat furnace slowly to remove absorbed moisture | Prevents steam-induced cracking; mandatory for new or inactive furnaces |

| Temperature Range | Typically 200°C to 600°C for several hours | Follow manufacturer's manual for specific guidelines |

| Safety Measures | Ensure proper ventilation; never exceed rated temperature | Avoids hazards and equipment damage |

| Consequences of Skipping | Risk of cracked insulation, damaged heating elements, and costly repairs | Emphasizes necessity of the procedure |

Ensure your muffle furnace operates safely and efficiently with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your lab's performance and prevent equipment failures!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do high-vacuum muffle furnaces or tube furnaces facilitate the activation of materials like UiO-66-NH2?

- What is the temperature limit on a muffle furnace? Find the Right Range for Your Lab

- What are some additional options available for Box Furnaces? Enhance Your Thermal Processing Efficiency

- How does the position of gas inlets in a muffle furnace affect the temperature distribution? Master Thermal Uniformity

- How are box furnaces utilized in electronic component manufacturing? Essential Thermal Processing for Electronics

- What role does a laboratory muffle furnace play in cotton waste biochar? Precision Pyrolysis for Carbonization

- How is a box resistance furnace or muffle furnace utilized when processing BCZT gel? Expert Powder Synthesis Guide

- What role do auxiliary equipment like fans and sprayers play in a box furnace? Enhance Precision and Efficiency in Heat Treatment