In material treatment, a muffle furnace is primarily used for high-temperature processes such as annealing, sintering, hardening, and calcination. These applications leverage the furnace's ability to provide a uniform, precisely controlled thermal environment that is isolated from the heating elements. This separation is critical for altering a material's physical properties without introducing contaminants that could compromise its integrity.

The core value of a muffle furnace is not simply reaching high temperatures, but doing so within an isolated chamber. This "muffle" design protects the material from direct contact with the heating source, preventing contamination and ensuring the purity of the final product.

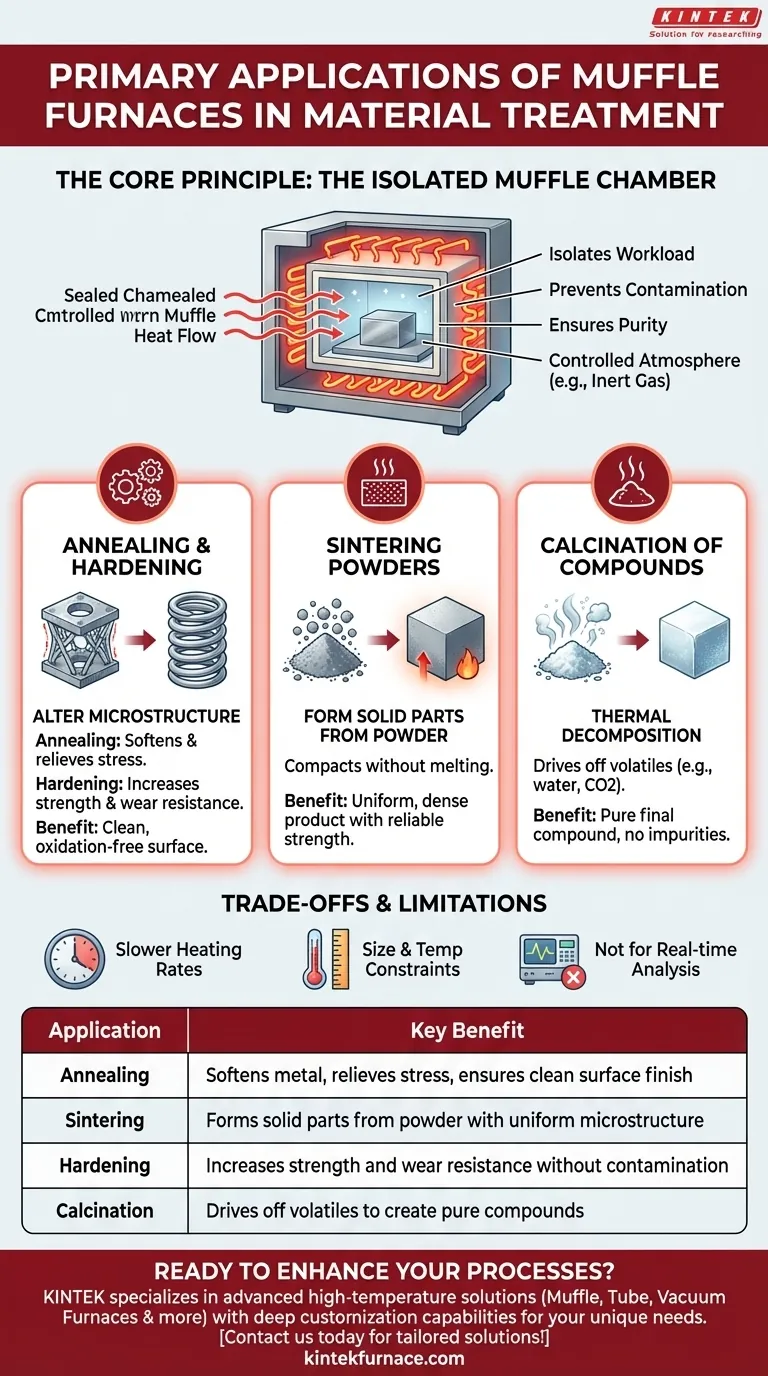

The Core Principle: Why a "Muffle" Matters

The defining feature of this furnace is the muffle itself—an insulated internal chamber that separates the workload from the heating elements. This design is fundamental to its applications in material treatment.

What Is a Muffle?

A muffle is a high-temperature-resistant box, often made of ceramic or a metal alloy. It contains the material being treated and is heated from the outside. Think of it as baking something in a covered ceramic dish placed inside a larger, hotter oven to protect it from direct flames.

Preventing Contamination

The primary benefit of the muffle is that it prevents contamination. Fuel, combustion byproducts, and particles shed from the heating elements cannot come into contact with the material being processed. This is essential for applications where surface purity and chemical integrity are paramount.

Ensuring Atmosphere Control

Because the chamber is sealed, the atmosphere inside can be controlled. While many processes run in air, the isolated environment allows for the introduction of inert gases (like argon or nitrogen) to prevent oxidation on sensitive metals during heat treatment.

Key Material Treatment Applications Explained

Each primary application takes advantage of the muffle furnace's clean, uniform heating capabilities to achieve a specific material outcome.

Annealing and Hardening Metals

These are heat treatment processes used to alter the microstructure of metals, thereby changing their mechanical properties. Annealing softens metal, increases its ductility, and relieves internal stresses. Hardening increases strength and wear resistance. The muffle furnace ensures a clean surface finish, free from the scale and oxidation that can occur in direct-fired furnaces.

Sintering Powders

Sintering is the process of compacting and forming a solid mass of material from a powder using heat, but without melting it to the point of liquefaction. This is a common method for producing ceramic components and certain metal parts. The uniform, contaminant-free heat from a muffle furnace is crucial for creating a dense final product with a uniform microstructure and reliable mechanical strength.

Calcination of Compounds

Calcination involves heating a material to a high temperature to drive off volatile substances, such as removing water from hydrates or carbon dioxide from calcium carbonate to produce lime. It is a thermal decomposition process. The controlled environment of a muffle furnace ensures that the reaction proceeds to completion without introducing impurities into the final compound.

Understanding the Trade-offs

While powerful, a muffle furnace is not the solution for every high-temperature task. Understanding its limitations is key to using it effectively.

Slower Heating Rates

The muffle itself acts as a layer of insulation between the heating elements and the workload. This means that heating and cooling cycles in a muffle furnace can be slower compared to direct-fired furnaces where the material is exposed directly to the heat source.

Temperature and Size Constraints

The material of the muffle (typically ceramic) has an upper temperature limit, and the design often restricts the furnace's internal volume. For very large industrial parts or processes requiring extremely high temperatures, other furnace types may be more suitable.

Not Ideal for All Analytical Work

While used for some analysis, a muffle furnace's primary role is treatment. For precise analytical tasks like thermogravimetric analysis (TGA), where mass change is measured in real-time as temperature changes, more specialized equipment is required.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on your objective for the material.

- If your primary focus is improving a material's properties: Use processes like annealing or sintering, where the muffle furnace provides the clean, uniform heat needed to modify the internal crystal structure.

- If your primary focus is creating a new compound from a precursor: Use calcination to drive chemical changes and remove unwanted volatiles in a controlled, pure environment.

- If your primary focus is determining a material's composition: Use ashing, where the furnace's role is to controllably burn away organic components for inorganic residue measurement.

Ultimately, understanding whether your goal is to treat, create, or analyze a material is the first step in leveraging a muffle furnace effectively.

Summary Table:

| Application | Key Benefit |

|---|---|

| Annealing | Softens metal, relieves stress, ensures clean surface finish |

| Sintering | Forms solid parts from powder with uniform microstructure |

| Hardening | Increases strength and wear resistance without contamination |

| Calcination | Drives off volatiles to create pure compounds |

Ready to enhance your material treatment processes with reliable, high-temperature solutions? KINTEK specializes in advanced muffle furnaces and other high-temperature systems like Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and deep customization capabilities, we can tailor solutions to meet your unique experimental needs for annealing, sintering, and more. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation