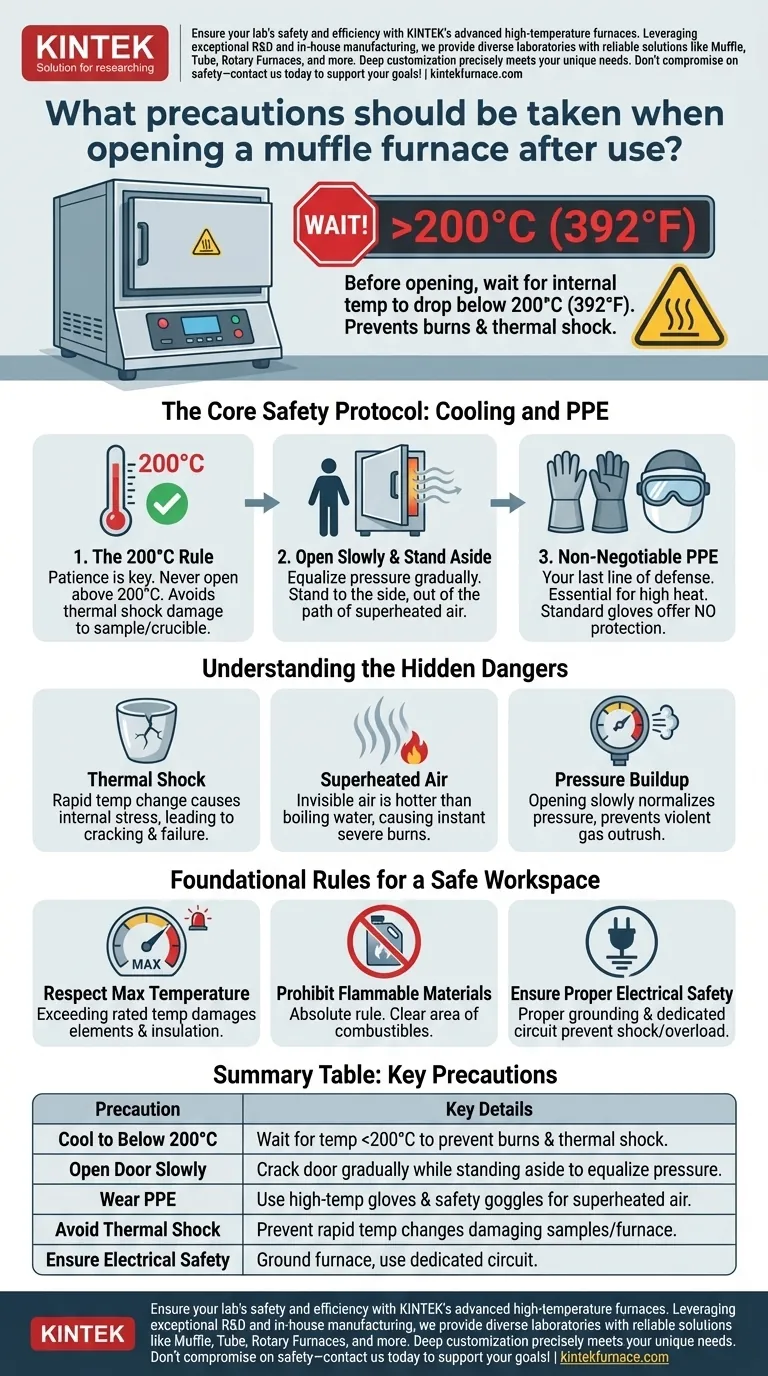

Before you open that furnace door, you must wait until the internal temperature drops below 200°C (392°F). Once cooled, the door must be opened slowly and deliberately while you stand to the side. Always wear high-temperature gloves and safety goggles, as a rush of superheated air can cause severe burns even without direct contact.

The critical takeaway is that opening a muffle furnace is not a simple action but a controlled procedure. The goal is to manage the release of extreme heat to prevent thermal shock—to yourself, your sample, and the furnace itself.

The Core Safety Protocol: Cooling and PPE

Properly opening a furnace after a heating cycle is a non-negotiable safety discipline. The risks of burns and equipment damage are significant, but they are also entirely preventable by following a clear, three-step protocol.

The 200°C Rule

The single most important precaution is patience. Never attempt to open the furnace door when the internal temperature is above 200°C.

High-temperature air is not only a burn risk but can also cause thermal shock to your sample or crucible, potentially cracking or destroying it upon contact with cooler ambient air.

Open Slowly and Stand Aside

When you open the door, do it slowly—just a crack at first. This allows the pressure and temperature to equalize gradually rather than in a sudden, dangerous burst.

Position your body to the side of the door, never directly in front of it. This ensures you are not in the path of the initial wave of superheated air that will inevitably escape.

Non-Negotiable Protective Gear

Your personal protective equipment (PPE) is your last line of defense. There are no safe shortcuts here.

- High-Temperature Gloves: These are essential for handling the door latch and for removing samples. Standard lab gloves offer no protection.

- Safety Goggles or Face Shield: Protects your eyes and face from the wave of superheated air and any potential debris.

Understanding the Hidden Dangers

The immediate heat is obvious, but other, less visible forces are at play when you open a furnace. Understanding them is key to appreciating why the safety protocols exist.

The Risk of Thermal Shock

Thermal shock occurs when a material experiences a rapid temperature change, causing internal stresses that can lead to cracking and failure.

This applies to the furnace's internal ceramic lining, the crucibles inside, and the sample itself. Opening the door too quickly on a hot furnace is a primary cause of this damage.

The Hazard of Superheated Air

The air inside a furnace, even at 200°C, is far hotter than boiling water and can cause instant, severe burns. Because it is invisible, operators can easily underestimate its danger.

Minimizing the door's opening time is crucial. Retrieve your sample efficiently and close the door promptly.

Preventing Pressure Buildup

While less common with standard atmospheric furnaces, heating volatile materials or creating sudden temperature changes can cause pressure shifts.

Opening the door slowly helps to normalize this pressure safely, preventing the door from being forced open unexpectedly or causing a violent outrush of hot gas.

Foundational Rules for a Safe Workspace

The precautions for opening a furnace are part of a larger system of safe operation. Ignoring these foundational rules undermines the entire process.

Respect the Maximum Temperature

Every muffle furnace has a rated maximum temperature. Exceeding it, even for a short time, can permanently damage the heating elements and refractory insulation, leading to costly repairs and unreliable performance.

Prohibit Flammable and Explosive Materials

This is an absolute rule. Never place flammable, volatile, or explosive materials inside a muffle furnace.

Furthermore, ensure the area around the furnace is completely clear of any combustible materials to prevent fire hazards.

Ensure Proper Electrical Safety

A muffle furnace is a high-power device that demands electrical respect. The unit must be properly grounded to prevent electric shock.

It should also be connected to a dedicated circuit with an appropriate power controller or gate to avoid overloading the system.

Making the Right Choice for Your Goal

Adhering to safety protocols is not about limitation; it's about enabling consistent, reliable, and safe results. Tailor your focus based on your primary objective.

- If your primary focus is personal safety: Always prioritize waiting for the temperature to drop below 200°C and wearing the correct PPE before opening the door.

- If your primary focus is equipment longevity: Avoid thermal shock by opening the door slowly and never exceeding the furnace's rated temperature.

- If your primary focus is sample integrity: Allow for a slow, controlled cooling process to prevent your materials from cracking or degrading due to thermal shock.

A disciplined and informed approach transforms the muffle furnace from a potential hazard into a reliable and powerful tool.

Summary Table:

| Precaution | Key Details |

|---|---|

| Cool to Below 200°C | Wait until internal temperature is under 200°C (392°F) to prevent burns and thermal shock. |

| Open Door Slowly | Crack door gradually while standing aside to equalize pressure and avoid hot air bursts. |

| Wear PPE | Use high-temperature gloves and safety goggles for protection from superheated air. |

| Avoid Thermal Shock | Prevent rapid temperature changes that can damage samples, crucibles, and furnace lining. |

| Ensure Electrical Safety | Ground the furnace and use a dedicated circuit to prevent electric shock and overloads. |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs, enhancing performance and longevity. Don't compromise on safety—contact us today to discuss how our products can support your goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites