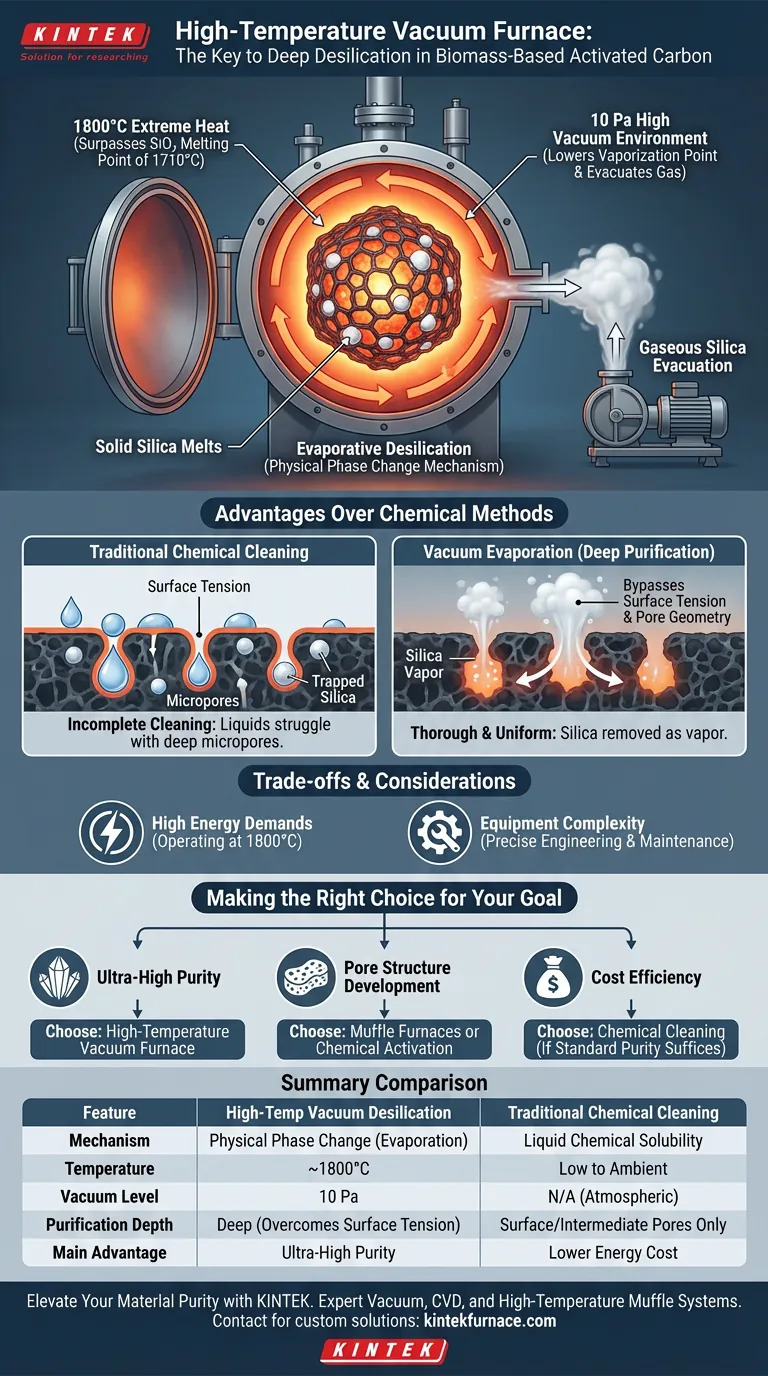

The primary role of a high-temperature vacuum furnace in desilication is to execute a physical phase change mechanism called evaporative desilication. By maintaining a high-vacuum environment of approximately 10 Pa and reaching temperatures around 1800°C, the furnace forces silicon dioxide (silica) to melt and evaporate directly out of the biomass-based charcoal. This process removes silica from deep within the carbon structure without relying on liquid solvents.

The core value of this equipment lies in its ability to overcome the surface tension limitations of chemical cleaning solutions. By inducing a phase change at extreme temperatures, the furnace achieves deep purification that liquid agents cannot replicate.

The Mechanics of Evaporative Desilication

Surpassing the Melting Point

The effectiveness of the furnace relies on its ability to generate extreme heat. Silicon dioxide has a melting point of 1710°C.

To ensure effective removal, the vacuum furnace operates at approximately 1800°C. This temperature buffer guarantees that the silica transitions from a solid state, facilitating its release from the carbon matrix.

The Function of Vacuum Pressure

Heat alone is often insufficient for efficient purification; the pressure environment is equally critical.

The furnace creates a high vacuum level of roughly 10 Pa. This low-pressure environment lowers the vaporization point of volatile impurities and facilitates the rapid evacuation of gaseous silica from the chamber.

Advantages Over Chemical Methods

Bypassing Surface Tension Issues

Traditional desilication often uses chemical cleaning solutions. However, these liquids struggle to penetrate the intricate pore structure of activated carbon.

Surface tension prevents chemical fluids from entering the smallest micropores. This results in incomplete cleaning, leaving silica trapped deep inside the material.

Achieving Thorough Purification

The high-temperature vacuum furnace utilizes a physical extraction method rather than a chemical one.

Because the process relies on thermal evaporation, it is not hindered by pore size or geometry. The silica is removed as a vapor, ensuring a more uniform and thorough reduction of ash content compared to wet chemical methods.

Understanding the Trade-offs

High Energy Demands

While physically superior for purity, this method is energy-intensive.

Operating at 1800°C requires significantly more power than the 500°C used in muffle furnaces for pyrolysis or the 800°C used for chemical activation. This impacts the overall operational cost of the production line.

Equipment Complexity

A vacuum furnace is mechanically more complex than standard atmospheric furnaces.

Maintaining a stable 10 Pa vacuum while managing extreme thermal loads requires precise engineering and rigorous maintenance. Unlike simple chemical soaking, this process demands specialized operator expertise.

Making the Right Choice for Your Goal

Selecting the right equipment depends heavily on the specific purity requirements and intended application of your activated carbon.

- If your primary focus is Ultra-High Purity: Prioritize the high-temperature vacuum furnace to remove deep-seated silica that chemical washes cannot reach.

- If your primary focus is Pore Structure Development: Focus on muffle furnaces (for pyrolysis) or chemical activation processes, which build the micropore network rather than purifying the material.

- If your primary focus is Cost Efficiency: Evaluate if the standard purity levels achieved by chemical cleaning are sufficient, avoiding the high energy costs of evaporative desilication.

By utilizing the physics of phase change rather than the chemistry of solubility, the vacuum furnace provides the definitive solution for high-grade silica removal.

Summary Table:

| Feature | High-Temp Vacuum Desilication | Traditional Chemical Cleaning |

|---|---|---|

| Mechanism | Physical Phase Change (Evaporation) | Liquid Chemical Solubility |

| Temperature | ~1800°C | Low to Ambient |

| Vacuum Level | 10 Pa | N/A (Atmospheric) |

| Purification Depth | Deep (Overcomes Surface Tension) | Surface/Intermediate Pores Only |

| Main Advantage | Ultra-High Purity | Lower Energy Cost |

Elevate Your Material Purity with KINTEK

Are you struggling with silica trapped deep within your activated carbon's micropores? Traditional methods can't compete with the precision of thermal evaporation. KINTEK provides industry-leading Vacuum, CVD, and High-Temperature Muffle systems engineered to handle the extreme 1800°C demands of evaporative desilication.

Backed by expert R&D and world-class manufacturing, our customizable lab and industrial furnaces are designed specifically for researchers and manufacturers who refuse to compromise on ash content reduction.

Ready to optimize your purification process? Contact KINTEK today for a custom solution.

Visual Guide

References

- Yuto YANAGIHARA, Mudtorlep Nisoa. New Silica Removal Technique by Vacuum Heating toward High-Performance Cryosorption Pumps Based on Biomass-Based Activated Carbon. DOI: 10.1585/pfr.19.1205012

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does an automated hardness tester play in evaluating steel component gas quenching processes? Verify Quality

- What components make up the vacuum system in a vacuum furnace? Explore the Key Parts for Optimal Performance

- Why does magnesium distillation use a two-stage pump? A strategic division of labor for efficiency.

- What is the purpose of using industrial heating during non-productive vacuum degassing phases? Protect Your Assets

- What industries commonly use vacuum furnace chillers? Discover Key Applications in Aerospace, Semiconductors & More

- What are the advantages of graphite furnace? Achieve Unmatched High-Temperature Performance

- How does a vacuum system facilitate antimony-tellurium alloy distillation? Maximize Purity with Low-Temp Separation

- What are the two material varieties commonly found in graphite insulated hot zones? Graphite Board vs. Felt Explained