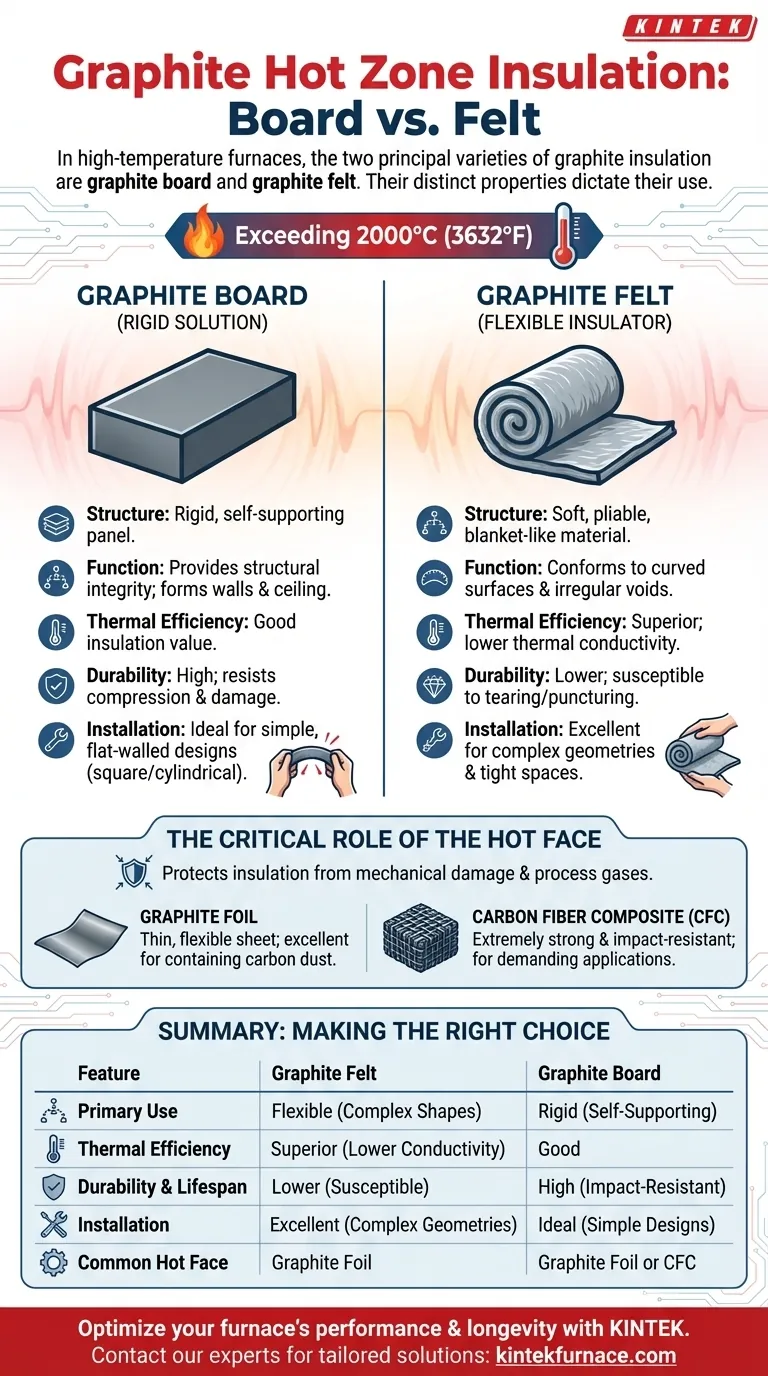

In high-temperature furnace applications, the two principal varieties of graphite insulation are graphite board and graphite felt. Both materials are designed to operate in extreme thermal environments, but their distinct physical forms and properties make them suitable for different structural and insulative requirements within a furnace's hot zone.

The decision between graphite board and felt is a critical engineering choice that balances structural rigidity against thermal performance. Rigid board provides durability and self-support, while flexible felt offers superior insulation, especially in complex or compact designs.

Understanding the Core Function

A hot zone is the heart of a vacuum or inert-atmosphere furnace, where the heating elements and the workload reside. The insulation's job is to contain this intense heat, ensuring temperature uniformity and protecting the furnace vessel from thermal damage.

Why Graphite?

Graphite is used for high-temperature insulation because of its unique properties. It has exceptional thermal stability, maintaining its integrity at temperatures exceeding 2000°C (3632°F) in a non-oxidizing environment.

In a vacuum, where convection is eliminated, graphite's low thermal conductivity makes it an outstanding insulator. It works primarily by reflecting thermal radiation back into the hot zone.

The Two Insulation Types: A Closer Look

While both are made from processed graphite fibers, their final form dictates their primary use case.

Graphite Felt: The Flexible Insulator

Graphite felt is a soft, pliable, blanket-like material. It is manufactured by carbonizing and then graphitizing a base material, typically rayon or polyacrylonitrile (PAN).

This flexibility is its main advantage, allowing it to conform perfectly to curved surfaces and fill irregular voids. Its low density and fibrous structure are excellent at minimizing heat transfer, giving it a superior insulation value (R-value) compared to board of the same thickness.

Graphite Board: The Rigid Solution

Graphite board is a rigid, self-supporting panel. It is made by either forming carbon-bonded fibers into a block and graphitizing it, or by laminating layers of felt together with a carbonaceous binder that is then cured and graphitized.

Its rigidity provides structural integrity, allowing it to form the walls and ceiling of the hot zone without needing a complex metal support frame. This makes hot zone design and assembly significantly simpler.

The Critical Role of the Hot Face

Both felt and board are porous and relatively fragile. To protect them from mechanical damage and erosion from high-velocity process gases, a protective "hot face" is installed on the interior surface.

Common Hot Face Materials

The reference-mentioned materials, graphite foil and Carbon Fiber Composite (CFC), are the industry standards.

Graphite foil is a thin, flexible sheet of pure graphite. It is excellent for containing carbon dust and protecting the underlying insulation from direct radiation and gas flow.

CFC, also known as Carbon-Carbon, is an extremely strong and impact-resistant material. It is used in the most demanding applications where there is a risk of contact with the workload during loading and unloading.

Understanding the Trade-offs: Board vs. Felt

Choosing the right material requires a clear understanding of the operational priorities.

Thermal Efficiency

For pure insulation performance, felt is superior. Its less-dense, more fibrous structure provides a more tortuous path for heat, resulting in lower thermal conductivity.

Durability and Lifespan

Board is significantly more durable. Its rigid structure resists compression and damage. When combined with a CFC hot face, a board-based hot zone offers the longest operational life and is far more resistant to accidental impacts. Felt is more susceptible to tearing or puncturing.

Installation and Design

Felt excels in complex geometries. It can be easily cut and fitted around heating elements, power feedthroughs, and sight ports. Board is ideal for simple, flat-walled designs like square or cylindrical hot zones, where its self-supporting nature simplifies construction.

Dust and Contamination

Felt can shed more fibers over time, which can be a concern in high-purity applications. A properly installed hot face, like graphite foil, effectively mitigates this issue for both materials.

Making the Right Choice for Your Application

Your furnace's specific function and operating conditions will determine the optimal insulation package.

- If your primary focus is maximum thermal efficiency or insulating a complex shape: Graphite felt is the superior choice due to its flexibility and lower thermal conductivity.

- If your primary focus is durability, long lifespan, and simplified construction: Rigid graphite board, especially when protected by a CFC hot face, provides the most robust and easy-to-assemble solution.

- If you are balancing cost against performance in a standard furnace: A hot zone constructed from graphite board with a simple graphite foil hot face often represents the best overall value.

Ultimately, understanding the distinct advantages of each material empowers you to engineer a hot zone that is both efficient and resilient for its intended task.

Summary Table:

| Feature | Graphite Felt | Graphite Board |

|---|---|---|

| Primary Use | Flexible insulation for complex shapes | Rigid, self-supporting structure |

| Thermal Efficiency | Superior (Lower thermal conductivity) | Good |

| Durability & Lifespan | Lower (Susceptible to damage) | High (Impact-resistant, especially with CFC face) |

| Installation | Excellent for complex geometries | Ideal for simple, flat-walled designs |

| Common Hot Face | Graphite Foil | Graphite Foil or Carbon Fiber Composite (CFC) |

Optimize your furnace's performance and longevity with the right graphite insulation solution.

At KINTEK, we leverage our deep expertise in high-temperature materials and in-house manufacturing to provide advanced, custom furnace solutions. Whether your priority is maximum thermal efficiency with graphite felt or superior durability with rigid board, our team will help you design the perfect hot zone for your specific application, including Muffle, Tube, Vacuum, and CVD/PECVD Systems.

Contact our experts today for a consultation to discuss your requirements and get a tailored solution that enhances your lab's capabilities.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating