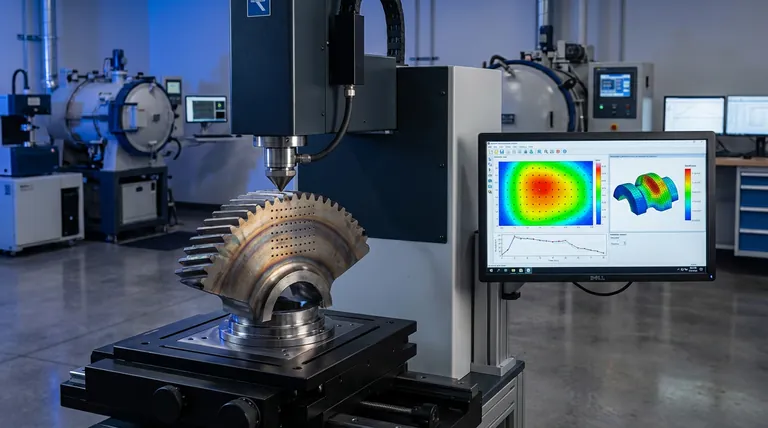

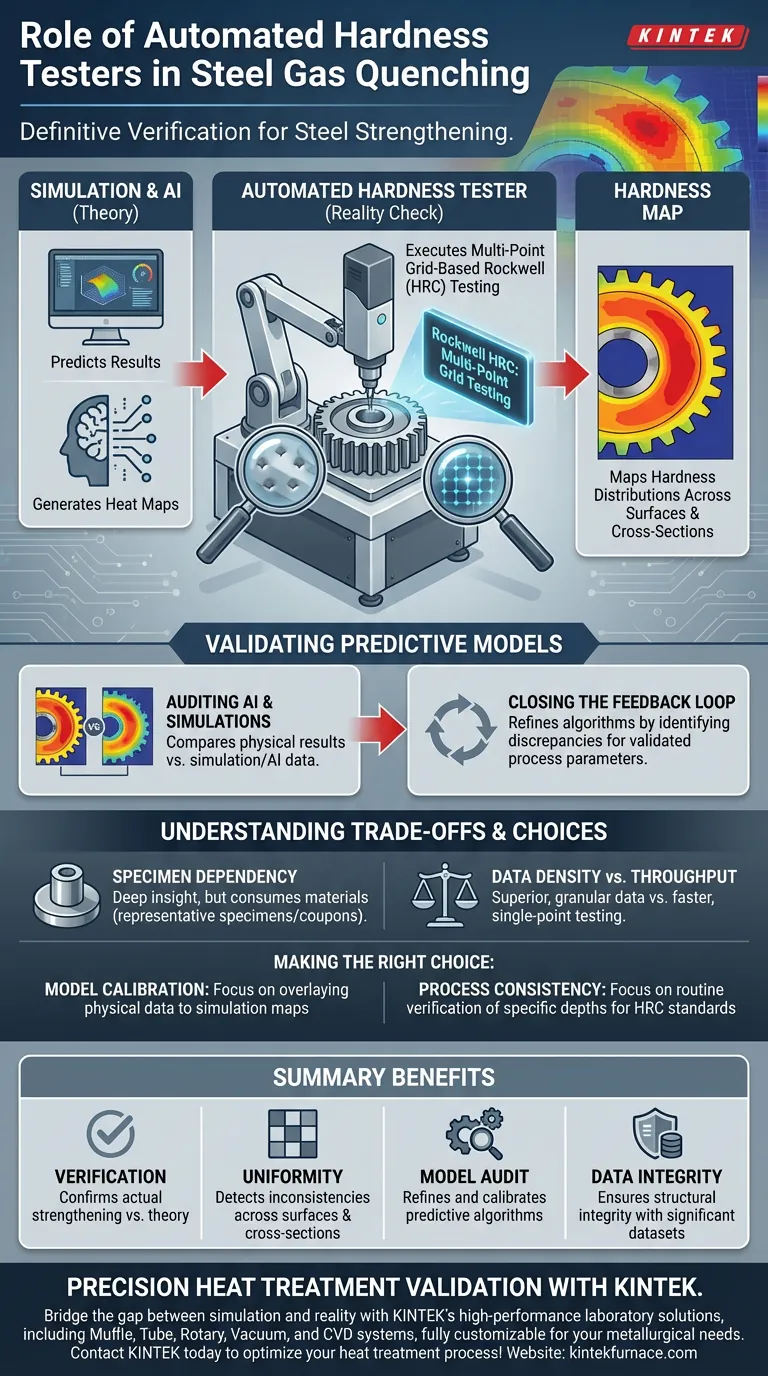

An automated hardness tester acts as the definitive verification mechanism for steel component gas quenching. It executes large-scale, multi-point Rockwell hardness (HRC) testing to physically confirm the strengthening effects achieved during the heat treatment process.

While simulations predict results, the automated hardness tester confirms reality. It maps hardness distributions across surfaces and cross-sections to validate the accuracy of predictive AI models and simulation data.

The Mechanism of Evaluation

Multi-Point Grid Testing

The device goes beyond simple spot-checking by performing comprehensive, grid-based indentation tests.

It creates a detailed map of hardness values across the specimen, rather than relying on a single data point.

Analyzing Depth and Uniformity

Testing is performed on both the exterior surface and the internal cross-sections of the component.

This dual approach provides direct feedback on how deeply and uniformly the gas quenching process has strengthened the steel.

Validating Predictive Models

Auditing AI and Simulations

The primary strategic role of the tester is to serve as a quality assessment tool for virtual models.

It compares physical results against data generated by simulation models and artificial intelligence systems.

Closing the Feedback Loop

By identifying discrepancies between predicted and actual hardness, engineers can refine their algorithms.

This ensures that future gas quenching cycles are based on validated, accurate process parameters.

Understanding the Trade-offs

Specimen Dependency

Because the process involves cross-section analysis, it often requires the use of representative specimens or sacrificial parts.

This provides deep insight but requires the consumption of materials or test coupons to verify the batch.

Data Density vs. Throughput

High-resolution grid testing generates superior data but requires more time than single-point manual testing.

You are trading speed for a granular, statistically significant view of the component's structural integrity.

Making the Right Choice for Your Goal

- If your primary focus is model calibration: Use the grid-based data to overlay physical hardness maps onto your simulation heat maps to identify deviations.

- If your primary focus is process consistency: Use the tester to routinely verify that the strengthening effects at specific cross-section depths meet the defined HRC standards.

Automated hardness testing bridges the gap between theoretical heat treatment design and physical manufacturing quality.

Summary Table:

| Evaluation Metric | Role of Automated Tester | Key Benefit |

|---|---|---|

| Verification | Executes multi-point grid-based Rockwell (HRC) testing | Confirms actual strengthening vs. theory |

| Uniformity | Maps hardness across surfaces and cross-sections | Detects inconsistencies in heat treatment |

| Model Audit | Compares physical results with AI/simulation data | Refines and calibrates predictive algorithms |

| Data Integrity | Provides granular, statistically significant datasets | Ensures structural integrity and compliance |

Precision Heat Treatment Validation with KINTEK

Bridge the gap between simulation and reality with reliable testing and high-temperature equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique metallurgical needs.

Whether you are refining AI quenching models or ensuring batch consistency, our advanced systems provide the thermal precision your steel components require. Contact KINTEK today to optimize your heat treatment process!

Visual Guide

References

- Artificial Intelligence Modeling of the Heterogeneous Gas Quenching Process for Steel Batches Based on Numerical Simulations and Experiments. DOI: 10.3390/dynamics4020023

This article is also based on technical information from Kintek Furnace Knowledge Base .

People Also Ask

- What is the advantage of using an integrated UHV preparation chamber? Ensure Pristine In2Se3 Surface Integrity

- Why is a vacuum sintering furnace essential for Ti-5Al-4W-2Fe alloys? Prevent Embrittlement & Maximize Density

- What materials can be used for retorts in hot wall furnaces? Choose the Right Material for Your Process

- How is temperature controlled during the heating process in a vacuum furnace? Unlock Precision for High-Integrity Processes

- How does a vacuum sublimation furnace with rheological movement benefit high-moisture coal? Optimize Production Speed

- Which materials are suitable for treatment in a vacuum annealing furnace? Protect Reactive Metals and Alloys

- What is the primary role of a vacuum melting furnace in Ti-Zr-Mo-W alloy prep? Ensure Purity and Homogeneity

- What happens during the heating phase of a vacuum furnace? Master Radiative Heat and Outgassing Control