A high-temperature tube furnace serves as the foundational reaction vessel for converting Polyethylene Oxide (PEO) into porous carbon, providing the strict environmental controls required for chemical transformation. It enables the precursor to undergo specific thermal decomposition without burning, ensuring the material evolves into a stable carbon framework.

The core function of the tube furnace is to decouple heat from combustion. By maintaining an inert atmosphere while delivering precise thermal energy, it forces PEO to undergo dehydrocondensation—stripping away non-carbon elements to leave behind a structured, porous skeleton.

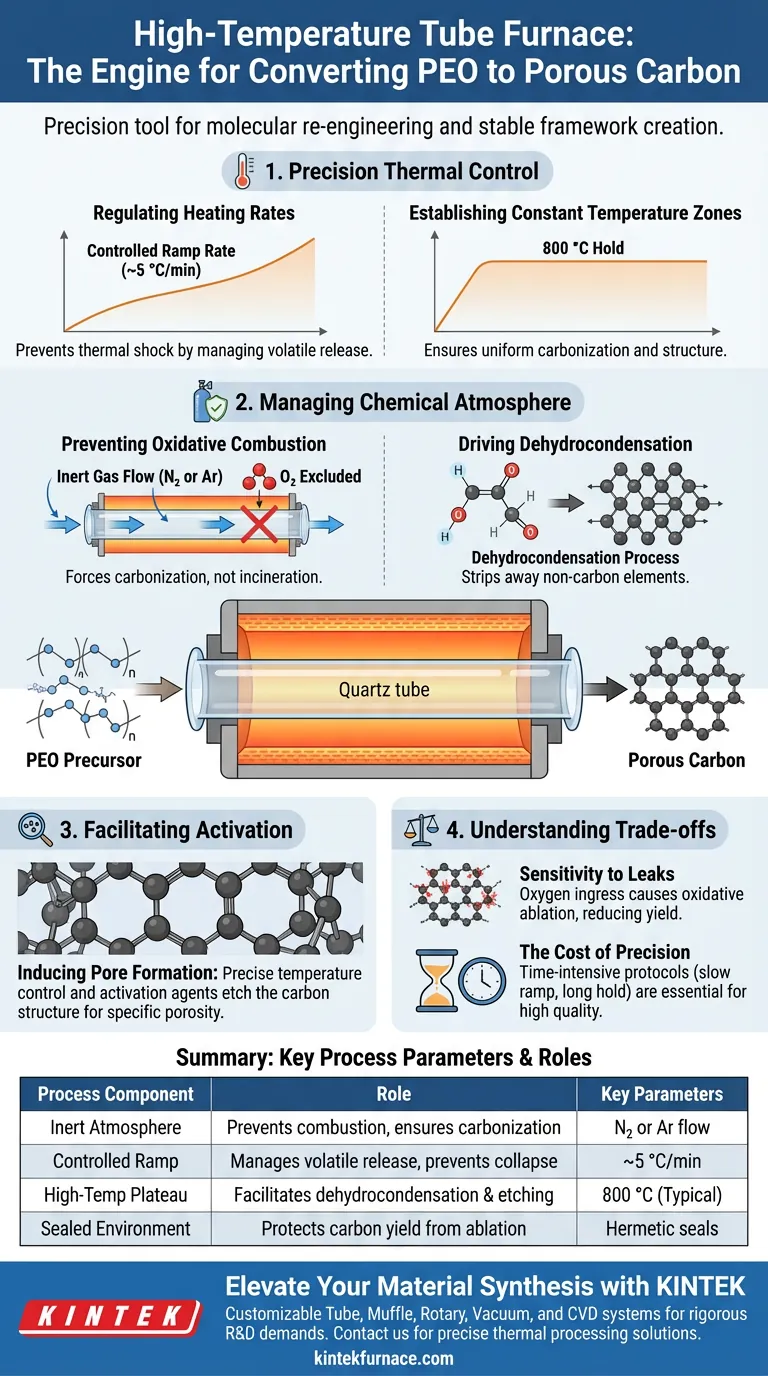

Precision Thermal Control

Regulating Heating Rates

The furnace does not simply blast the material with heat; it applies a controlled ramp rate, typically around 5 °C/min.

This gradual increase is critical for managing the release of volatile components. A slow, steady rise ensures that the organic structure evolves methodically rather than collapsing under thermal shock.

Establishing Constant Temperature Zones

Once the ramp is complete, the furnace maintains a stable high-temperature environment, often targeting 800 °C.

Holding the material at this specific thermal plateau allows the carbonization process to complete. It ensures the entire sample reaches thermal equilibrium, resulting in a uniform material structure.

Managing the Chemical Atmosphere

Preventing Oxidative Combustion

The most vital role of the tube furnace is creating an inert atmosphere (usually Nitrogen or Argon).

If PEO were heated to 800 °C in open air, it would simply burn away. The sealed tube environment prevents oxygen from reacting with the sample, forcing the material to carbonize rather than incinerate.

Driving Dehydrocondensation

In this oxygen-deprived environment, the heat drives a specific chemical reaction known as dehydrocondensation.

This process systematically removes hydrogen and oxygen atoms from the PEO chain. What remains is a condensed carbon framework, which forms the physical backbone of the final porous material.

Facilitating Activation

Inducing Pore Formation

Beyond simple carbonization, the furnace facilitates the activation process necessary to create porosity.

Whether through thermal decomposition alone or with the aid of chemical agents, the precise temperature control allows for the "etching" of the carbon structure. This creates the specific pore architecture required for the material's end application.

Understanding the Trade-offs

Sensitivity to Atmospheric Leaks

The effectiveness of the process is entirely dependent on the integrity of the seal.

Even a minor ingress of oxygen at 800 °C leads to "oxidative ablation," where the carbon skeleton is eaten away, significantly reducing yield and damaging pore structure.

The Cost of Precision

Achieving high-quality porous carbon requires time-intensive protocols.

The slow heating rates (e.g., 5 °C/min) and long hold times required for deep pyrolysis mean that throughput is limited. Rushing this process to save time typically results in incomplete carbonization or a collapsed pore network.

Making the Right Choice for Your Goal

To maximize the utility of a high-temperature tube furnace for PEO conversion, align your settings with your specific objectives:

- If your primary focus is structural stability: Prioritize slower heating rates (below 5 °C/min) to allow volatiles to escape without damaging the developing carbon framework.

- If your primary focus is pore surface area: focus on the precision of the high-temperature hold (800 °C) and the inert gas flow to maximize the activation effect without ablation.

Ultimately, the tube furnace acts not just as a heater, but as a precise instrument for molecular re-engineering.

Summary Table:

| Process Component | Role in PEO Conversion | Key Parameters |

|---|---|---|

| Inert Atmosphere | Prevents oxidative combustion; ensures carbonization | Nitrogen or Argon flow |

| Controlled Ramp | Manages volatile release; prevents structural collapse | ~5 °C/min |

| High-Temp Plateau | Facilitates dehydrocondensation & pore etching | 800 °C (Typical) |

| Sealed Environment | Protects carbon yield from oxidative ablation | Hermetic tube seals |

Elevate Your Advanced Material Synthesis with KINTEK

Precise carbonization requires more than just heat—it requires absolute environmental control. KINTEK provides high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of molecular re-engineering.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to handle your specific ramp rates, atmosphere requirements, and thermal plateaus. Whether you are developing porous carbon for energy storage or advanced filtration, we deliver the stability and precision your research deserves.

Ready to optimize your thermal processing? Contact KINTEK today for a custom solution.

Visual Guide

References

- Pawan Singh Dhapola, Pramod K. Singh. Environment-friendly approach for synthesis of promising porous carbon: empowering supercapacitors for a sustainable future. DOI: 10.1039/d3ma00984j

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is the chemical composition of the alloy used in tube reactors critical? Insights into Ethane Cracking Results

- Why is high-temperature annealing in a tube furnace necessary for LaAlO3? Optimize TiO2 Thin Film Adhesion

- What is the specific purpose of tilting a tube resistance furnace during synthesis? Maximize Yield & Crystal Quality

- How is temperature regulation achieved in a High Temperature Tube Furnace? Master Precise Control for Your Lab

- What is the function of a tube furnace in catalyst annealing? Unlock L10 Ordered Structures for Peak Performance

- Why are tube furnaces considered essential for scientific research? Unlock Precise High-Temperature Control

- Why is pre-oxidation treatment of the substrate in a tube furnace necessary? Ensure Strong Ti(Nb)-Si-C Coating Adhesion

- What is the primary function of a tube furnace in CVD synthesis of carbon nanotubes? Achieve Precision Thermal Control