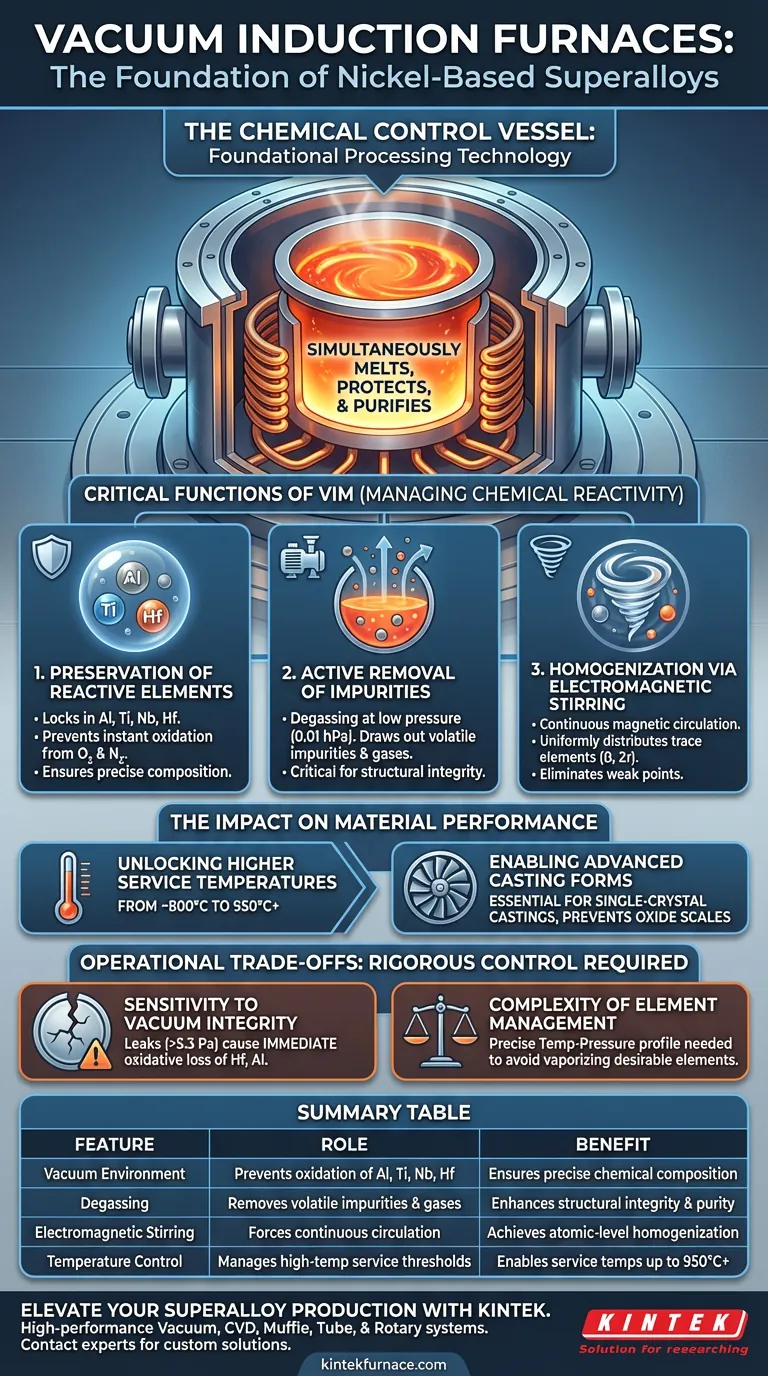

Vacuum induction furnaces serve as the foundational processing technology for the production of nickel-based superalloys, fundamentally determining the quality of the material. By operating within a high-vacuum environment (typically 1.4 to 5.3 Pa) and utilizing electromagnetic principles, these furnaces simultaneously melt the alloy, protect its chemistry, and actively purify the liquid metal.

The Core Takeaway The vacuum induction furnace is not merely a heat source; it is a chemical control vessel. Its primary function is to prevent the oxidation of reactive strengthening elements (like aluminum and titanium) while utilizing electromagnetic stirring to ensure the atomic-level homogeneity required for high-performance superalloys.

The Critical Functions of Vacuum Induction Melting (VIM)

The preparation of nickel-based superalloys is less about melting metal and more about managing chemical reactivity. The vacuum induction furnace achieves this through three distinct mechanisms.

Preservation of Reactive Elements

Nickel-based superalloys rely on reactive elements such as aluminum (Al), titanium (Ti), niobium (Nb), and hafnium (Hf) for strength.

In a standard atmosphere, these elements would instantly react with oxygen and nitrogen, forming oxide inclusions and degrading the alloy. The vacuum environment effectively "locks in" these elements, preventing oxidative loss and ensuring the final composition matches the precise design specifications.

Active Removal of Impurities

The vacuum environment performs a cleaning function known as degassing.

Under low pressure (down to 0.01 hPa or lower), volatile impurities and dissolved gases are drawn out of the alloy liquid. This purification is critical for preventing defects that could lead to structural failure under high-stress conditions.

Homogenization via Electromagnetic Stirring

A unique advantage of induction heating is the generation of strong electromagnetic stirring within the melt.

Unlike static melting methods, the magnetic field forces the molten metal to circulate continuously. This ensures that trace elements—specifically grain boundary strengtheners like boron (B) and zirconium (Zr)—are distributed uniformly throughout the complex nickel matrix.

The Impact on Material Performance

The transition to vacuum induction technology was a pivot point in metallurgical history, directly enabling the high-temperature capabilities of modern engines.

Unlocking Higher Service Temperatures

Before vacuum technology, alloy chemistry was limited by what could survive air melting.

Vacuum processing allowed for higher concentrations of strengthening elements (Al, Ti, Ta). This advancement raised the service temperature of deformed superalloys from roughly 800°C to 950°C.

Enabling Advanced Casting Forms

For advanced applications like single-crystal castings (e.g., CM186LC alloy), the purity provided by the vacuum furnace is non-negotiable.

By maintaining extremely low oxygen content, the furnace prevents the formation of oxide scales that would disrupt the single-crystal growth, ensuring the mechanical integrity of the final component.

Understanding the Operational Trade-offs

While vacuum induction furnaces are essential, they require rigorous control to be effective.

Sensitivity to Vacuum Integrity

The process is intolerant of leaks or pump failures. Even a minor breach in the vacuum seal (rising above the 1.4–5.3 Pa range) can result in the immediate oxidative loss of critical elements like Hafnium and Aluminum, ruining the batch.

Complexity of Element Management

While the vacuum removes gases, it can also vaporize desirable elements with high vapor pressures if the temperature and vacuum levels are not perfectly balanced. Operators must precisely manage the temperature-pressure profile to remove impurities without depleting the alloy's active ingredients.

Making the Right Choice for Your Goal

The specific benefits of a vacuum induction furnace depend on the performance metrics you are targeting for your alloy.

- If your primary focus is High-Temperature Strength: Rely on the vacuum environment to maximize the retention of reactive strengtheners like Aluminum and Titanium, which directly correlate to increased service temperatures (up to 950°C+).

- If your primary focus is Structural Reliability: Prioritize the electromagnetic stirring capability to ensure the uniform distribution of trace elements (Boron, Zirconium), eliminating weak points in the alloy's microstructure.

- If your primary focus is Single-Crystal Casting: Focus on the furnace's ability to maintain extremely low oxygen levels, which is the fundamental requirement for preventing defects in complex crystal structures.

Success in superalloy production is defined by the ability to control chemistry at the atomic level, a capability provided almost exclusively by vacuum induction melting.

Summary Table:

| Feature | Role in Superalloy Production | Primary Benefit |

|---|---|---|

| Vacuum Environment | Prevents oxidation of Al, Ti, Nb, and Hf | Ensures precise chemical composition |

| Degassing | Removes volatile impurities and dissolved gases | Enhances structural integrity and purity |

| Electromagnetic Stirring | Forces continuous circulation of molten metal | Achieves atomic-level homogenization |

| Temperature Control | Manages high-temperature service thresholds | Enables service temps up to 950°C+ |

Elevate Your Superalloy Production with KINTEK

Precision in chemistry is the difference between material success and failure. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, CVD, Muffle, Tube, and Rotary systems designed to meet the rigorous demands of modern metallurgy. Whether you are producing single-crystal castings or high-strength deformed alloys, our customizable lab high-temp furnaces provide the vacuum integrity and thermal control you need.

Ready to optimize your melting process? Contact our experts today to find the perfect furnace solution for your unique requirements.

Visual Guide

References

- Sergiy Byelikov, Sergiy Pychek. COMPARATIVE ANALYSIS OF THE COMPLEX OF PROPERTIES OF NICKEL-BASED SUPERALLOY. DOI: 10.15588/1607-6885-2025-1-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does an IGBT Vacuum Induction Melting Furnace operate? Achieve Ultra-High-Purity Metal Melting

- What are the advantages of industrial-grade induction furnaces for aluminum alloy production? Scale Your Mass Production

- What are some common operational issues with induction-heated vacuum furnaces and how can they be addressed? Boost Reliability and Efficiency

- What makes IGBT technology advantageous for induction heating? Achieve Precision, Efficiency, and Speed

- What is inductive stirring in melting applications? Master Metallurgical Control for Superior Melt Quality

- What is the role of a Vacuum Induction Melting (VIM) furnace? Precision Control for High-Performance Alloy Steels

- What is the capacity range of induction furnaces? From 1kg to 100+ tons for any production goal

- How do induction furnaces enhance safety during the smelting process? Achieve Cleaner, Safer Metal Melting