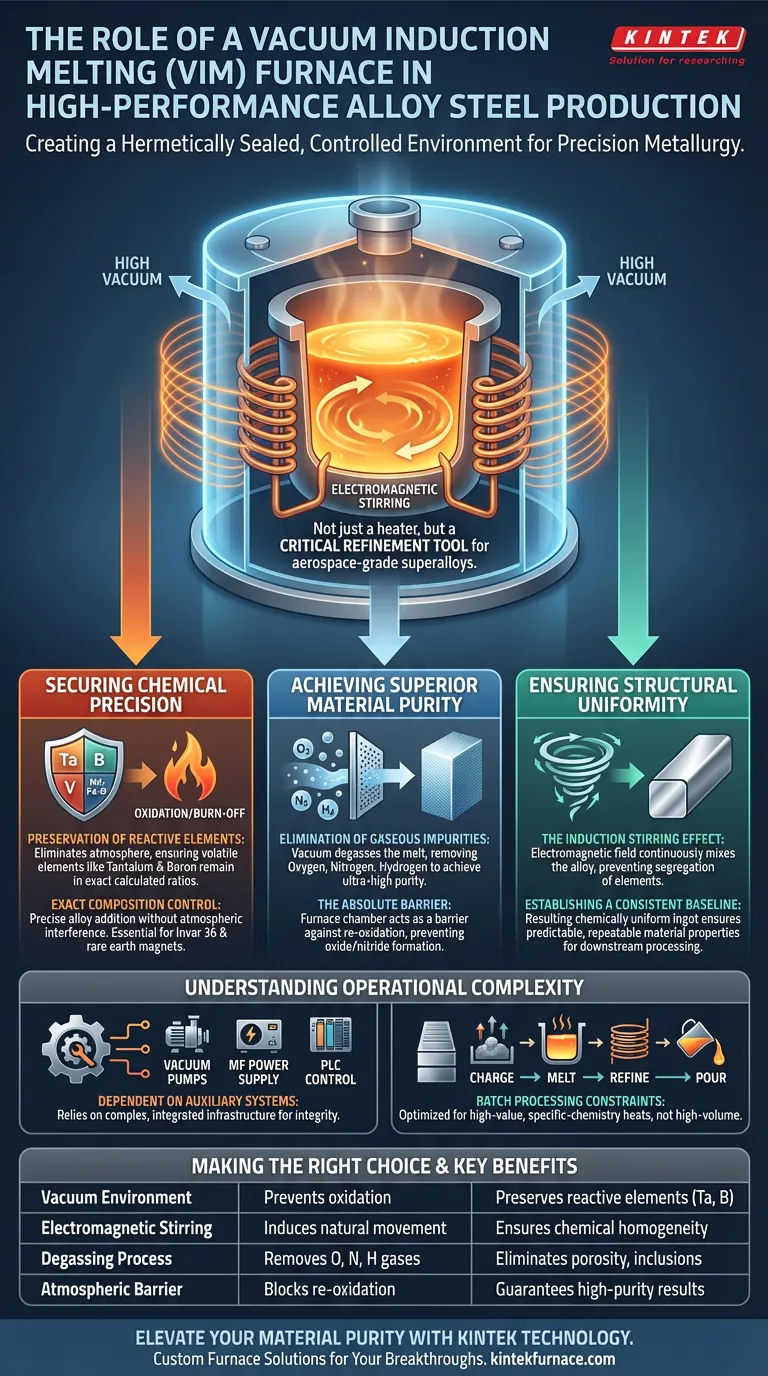

The primary role of a Vacuum Induction Melting (VIM) furnace is to create a hermetically sealed, controlled environment for processing high-performance alloys. By melting metal under a high vacuum, the furnace prevents the oxidative loss of reactive elements like tantalum and boron, ensuring the final chemical composition is precise. Additionally, the electromagnetic nature of the heating source induces a stirring effect, guaranteeing a chemically homogeneous ingot that serves as a reliable foundation for advanced manufacturing.

The VIM furnace is not simply a heating device; it is a critical refinement tool that eliminates atmospheric contamination and locks in the precise chemistry required for aerospace-grade superalloys and high-purity steels.

Securing Chemical Precision

Preservation of Reactive Elements

In open-air melting, reactive alloying elements such as tantalum, vanadium, and boron interact with oxygen and "burn off" before they can integrate into the steel.

The VIM furnace solves this by eliminating the atmosphere. This protection ensures that these volatile elements remain in the melt at the exact ratios calculated by the metallurgist.

Exact Composition Control

The vacuum environment allows for the precise addition of alloy components without the variable of atmospheric interference.

This capability is essential for materials like Invar 36 or rare earth magnets (such as Nd-Fe-B), where even slight deviations in chemical ratios can drastically alter physical or magnetic performance.

Achieving Superior Material Purity

Elimination of Gaseous Impurities

High-performance steels require a microstructure free from gas porosity and inclusions.

VIM technology effectively removes gaseous impurities, specifically oxygen, nitrogen, and hydrogen. The vacuum pressure draws these gases out of the molten metal, degassing the material to a level of purity that traditional melting methods cannot achieve.

The Absolute Barrier

The furnace chamber acts as an absolute barrier against re-oxidation.

By utilizing vacuum pumps or backfilling with high-purity inert gases like argon, the system creates a pristine environment. This prevents the formation of oxides and nitrides that would otherwise compromise the structural integrity of the final product.

Ensuring Structural Uniformity

The Induction Stirring Effect

A unique advantage of the VIM furnace is the electromagnetic field generated by the copper induction coil.

This field creates a natural stirring action within the molten metal bath. This movement continuously mixes the alloy, preventing segregation of heavier or lighter elements.

Establishing a Consistent Baseline

The result of this stirring is a chemically uniform ingot.

This uniformity is critical because it establishes a consistent base for subsequent thermal processing. Whether the material is destined for a turbine blade or a semiconductor, the VIM process ensures the material properties are predictable and repeatable throughout the entire ingot.

Understanding the Operational Complexity

Dependent on Auxiliary Systems

Unlike simple electric arc furnaces, a VIM system relies heavily on complex supporting infrastructure.

The supplementary references highlight the need for vacuum systems, medium frequency power supplies, and specialized tilting mechanisms. The performance of the furnace is entirely dependent on the integrity of the vacuum seal and the precise control of the PLC (Programmable Logic Controller).

Batch Processing Constraints

The VIM process is typically a batch operation involving charging, melting, refining, and pouring within a sealed chamber.

This makes it inherently different from continuous casting methods. It is optimized for high-value, specific-chemistry heats rather than high-volume, low-grade steel production.

Making the Right Choice for Your Goal

The VIM furnace is the industry standard for applications where material failure is not an option.

- If your primary focus is Chemical Stability: Use VIM to retain volatile elements like boron and tantalum that are critical for alloy strength.

- If your primary focus is Microstructural Cleanliness: Rely on VIM to degas the melt, removing hydrogen and nitrogen to prevent embrittlement and porosity.

- If your primary focus is Uniformity: Leverage the induction stirring effect to ensure the alloy composition is identical at every point in the ingot.

VIM technology transforms metal production from a bulk industrial process into a precise chemical science, enabling the creation of materials that define modern high-performance engineering.

Summary Table:

| Key Feature | Functional Role | Core Benefit |

|---|---|---|

| Vacuum Environment | Prevents oxidation and atmospheric contamination | Preserves reactive elements (Tantalum, Boron) |

| Electromagnetic Stirring | Induces natural movement in the molten bath | Ensures chemical homogeneity and uniformity |

| Degassing Process | Removes oxygen, nitrogen, and hydrogen gases | Eliminates porosity and structural inclusions |

| Atmospheric Barrier | Blocks re-oxidation via vacuum or inert gas | Guarantees high-purity, aerospace-grade results |

Elevate Your Material Purity with KINTEK Technology

Precision in metallurgy demands more than just heat; it requires an environment where chemistry is perfectly preserved. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems, all customizable to meet your unique laboratory and production needs.

Whether you are developing aerospace-grade superalloys or high-purity steels, our advanced furnace solutions provide the control and uniformity your research deserves. Contact us today to discuss your custom furnace requirements and see how our expertise can drive your next material breakthrough.

Visual Guide

References

- Russell Goodall, Jack Haley. Development of a boron-containing reduced activation Ferritic-Martensitic (B-RAFM) steel. DOI: 10.1177/03019233241273484

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What role do high-power heating plates play in vacuum contact drying furnaces? Unlock Rapid Thermal Diffusion

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?