Industrial-grade induction furnaces offer a pathway to mass production that laboratory equipment cannot match. Unlike laboratory vacuum setups, these furnaces enable large-scale melting under standard conditions while using electromagnetic stirring to ensure the chemical homogeneity required for aluminum-based complex concentrated alloys.

Moving production from laboratory vacuum environments to industrial-grade induction furnaces proves that complex alloys can be manufactured under standard conditions. This transition offers superior economic feasibility and scalable mass production without sacrificing alloy uniformity.

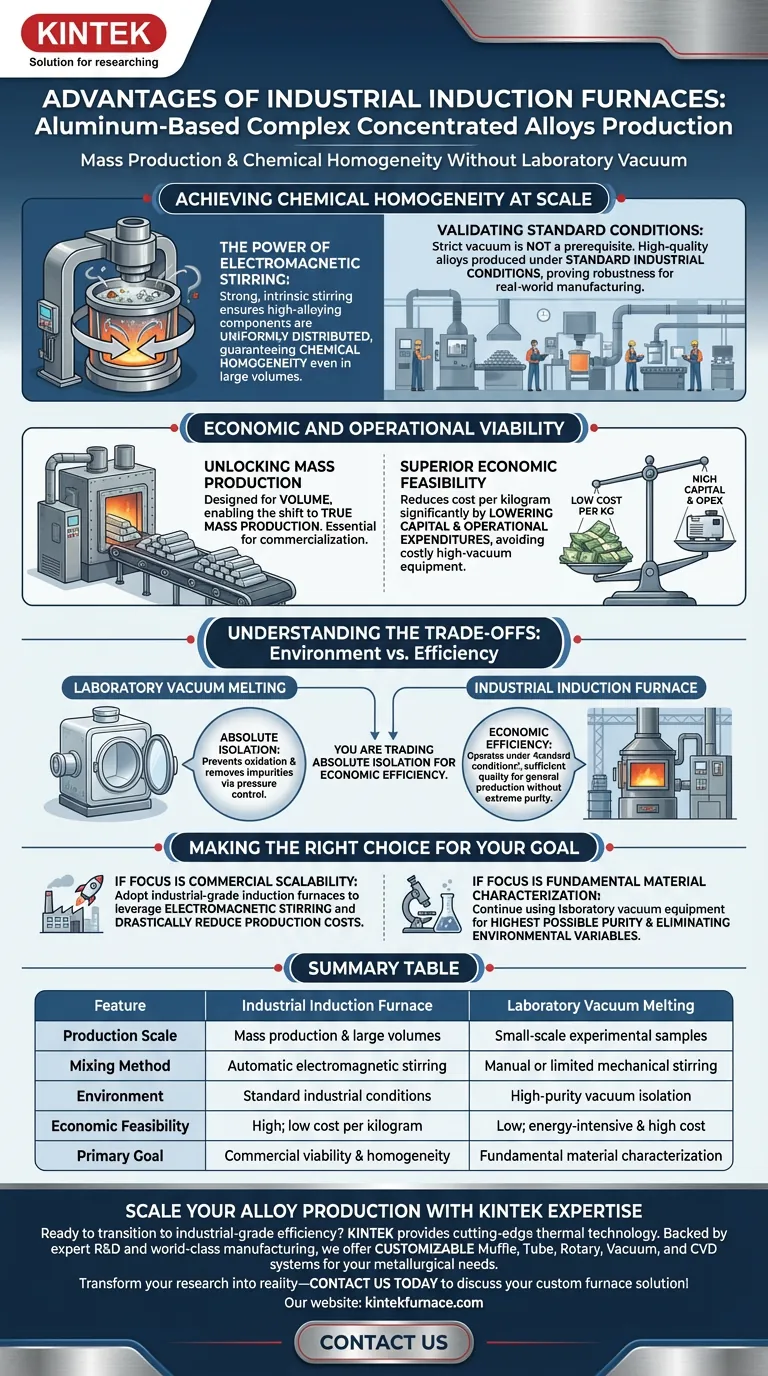

Achieving Chemical Homogeneity at Scale

The Power of Electromagnetic Stirring

A critical challenge in producing complex concentrated alloys is ensuring that various alloying elements mix perfectly. Industrial-grade induction furnaces utilize electromagnetic induction to provide a strong, intrinsic stirring effect within the melt.

This vigorous agitation ensures that high-alloying components are uniformly distributed throughout the aluminum matrix. It guarantees chemical homogeneity even when processing significantly larger volumes of metal than laboratory equipment can handle.

Validating Standard Conditions

Historically, these alloys were restricted to high-purity laboratory vacuum environments to prevent contamination. The use of industrial-grade furnaces demonstrates that strict vacuum environments are not a prerequisite for successful manufacturing.

High-quality alloys can be produced under standard industrial conditions. This insight removes a significant technical barrier, proving the material is robust enough for real-world manufacturing environments.

Economic and Operational Viability

Unlocking Mass Production

Laboratory vacuum equipment is inherently limited by size and throughput. Industrial induction furnaces are designed for volume, enabling the shift from small experimental samples to true mass production.

This capability is essential for commercializing aluminum-based complex concentrated alloys. It transforms the material from a research curiosity into a viable industrial product.

Superior Economic Feasibility

Operating high-vacuum laboratory equipment is energy-intensive and costly per unit of material produced. Industrial-grade induction melting offers superior economic feasibility by reducing the cost per kilogram of the alloy.

By utilizing standard conditions rather than specialized vacuum environments, manufacturers can significantly lower capital and operational expenditures.

Understanding the Trade-offs

Environment vs. Efficiency

While industrial furnaces excel at scale and stirring, they operate under "standard conditions" rather than the pristine environment of a vacuum lab. You are trading absolute environmental isolation for economic efficiency.

Laboratory vacuum melting prevents oxidation and removes impurities more effectively through pressure control. However, the primary reference indicates that for these specific aluminum-based alloys, the industrial induction process yields sufficient quality, making the extreme purity of a lab vacuum unnecessary for general production.

Making the Right Choice for Your Goal

- If your primary focus is commercial scalability: Adopt industrial-grade induction furnaces to leverage electromagnetic stirring for homogeneity while drastically reducing production costs.

- If your primary focus is fundamental material characterization: Continue using laboratory vacuum equipment to eliminate environmental variables and maintain the highest possible purity levels.

Industrial induction melting bridges the gap between the lab and the factory, making complex aluminum alloys a commercially viable reality.

Summary Table:

| Feature | Industrial Induction Furnace | Laboratory Vacuum Melting |

|---|---|---|

| Production Scale | Mass production & large volumes | Small-scale experimental samples |

| Mixing Method | Automatic electromagnetic stirring | Manual or limited mechanical stirring |

| Environment | Standard industrial conditions | High-purity vacuum isolation |

| Economic Feasibility | High; low cost per kilogram | Low; energy-intensive & high cost |

| Primary Goal | Commercial viability & homogeneity | Fundamental material characterization |

Scale Your Alloy Production with KINTEK Expertise

Ready to transition from laboratory experiments to industrial-grade efficiency? KINTEK provides the cutting-edge thermal technology you need to succeed. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique metallurgical requirements.

Whether you are refining aluminum-based complex concentrated alloys or developing new high-temp materials, our high-performance furnaces ensure chemical homogeneity and operational excellence.

Transform your research into reality—Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Compositional Design, Microstructure, and Thermal Processing of Aluminum-Based Complex Concentrated Alloys. DOI: 10.3390/cryst15010088

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the key components of an IGBT-based induction heater circuit? Unlock Efficient High-Frequency Heating

- Why is operating in a vacuum environment important for melting certain metal alloys? Achieve Superior Purity and Performance

- What role does a vacuum induction melting furnace play in AHSS research? Master Purity in High-Strength Steel Ingots

- What are the overall benefits of medium frequency induction furnaces in industrial applications? Achieve Rapid, Precise, and Clean Heating

- Why is the use of industrial-grade Vacuum Induction Melting (VIM) or electric arc furnaces essential for producing high-performance Medium-Manganese Steel (MMnS)?

- How can I reduce the power consumption of my induction furnace? Achieve Major Energy Savings Now

- What is the historical background of induction furnace development? From Faraday to Modern Metallurgy

- What are the differences between induction-heated and resistance-heated vacuum furnaces? Choose the Right Heating Method for Your Lab