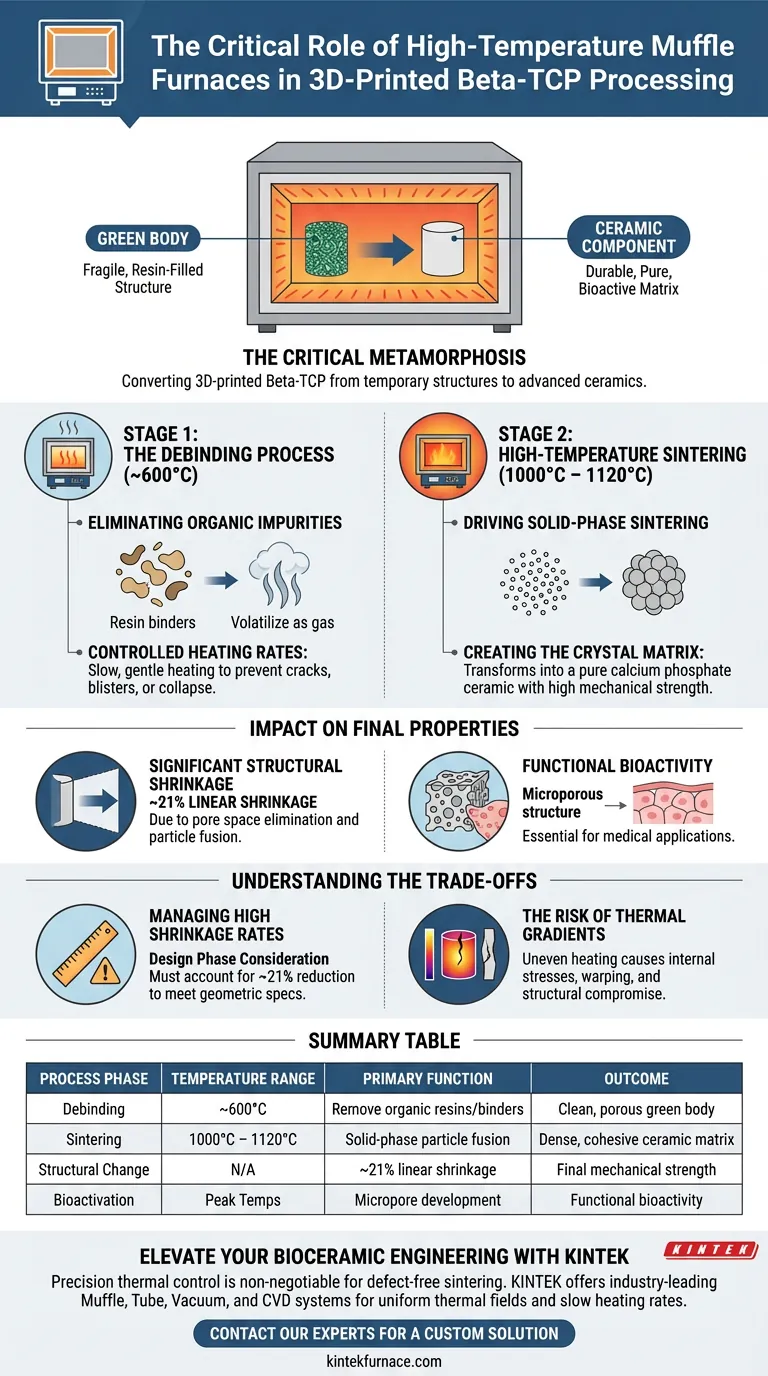

High-temperature muffle furnaces serve as the central processing unit for converting 3D-printed beta-tricalcium phosphate (beta-TCP) from fragile "green bodies" into durable ceramic components. These furnaces execute a precise, dual-stage thermal cycle that first removes organic binders and subsequently fuses the ceramic particles. Without this controlled thermal environment, the printed structures would lack the purity, strength, and biological activity required for medical applications.

The muffle furnace facilitates a critical metamorphosis: it transitions the material from a resin-filled temporary structure to a pure, solid-phase ceramic. This is achieved by sequentially eliminating impurities at 600°C and driving particle fusion at temperatures up to 1120°C, resulting in a significantly denser, biologically active matrix.

Stage 1: The Debinding Process

Eliminating Organic Impurities

The initial role of the muffle furnace is to perform debinding, typically managed at temperatures around 600°C.

During this phase, the furnace heat causes the resin binders and organic impurities used during printing to decompose and volatilize.

Controlled Heating Rates

Precision is vital during this stage; the furnace must apply slow heating rates to ensure organics are removed gently.

If the temperature rises too quickly, the rapid gas generation can cause cracks, blisters, or structural collapse within the delicate green body.

Stage 2: High-Temperature Sintering

Driving Solid-Phase Sintering

Once the binder is removed, the furnace temperature is ramped up to the 1000°C–1120°C range.

At this thermal plateau, the process shifts to solid-phase sintering, where the beta-TCP ceramic particles begin to bond and fuse at the atomic level.

Creating the Crystal Matrix

This high-heat environment transforms the loose powder structure into a cohesive pure calcium phosphate ceramic matrix.

The sustained heat ensures the final component achieves the necessary mechanical strength to function effectively as a bone substitute or scaffold.

Impact on Final Material Properties

Significant Structural Shrinkage

The densification process inside the furnace results in substantial physical changes, specifically a linear shrinkage of approximately 21%.

This reduction in volume is a direct result of the elimination of pore space as particles fuse together.

Functional Bioactivity

Beyond mere strength, the furnace treatment creates a precise microporous structure.

This structure is essential for biological activity, allowing the final ceramic component to interact successfully with biological tissues.

Understanding the Trade-offs

Managing High Shrinkage Rates

The 21% linear shrinkage driven by the muffle furnace is a significant dimensional change that must be accounted for during the initial design phase.

Failure to calculate this reduction accurately will result in final parts that do not meet geometric specifications.

The Risk of Thermal Gradients

While muffle furnaces are designed for uniformity, any inconsistency in the thermal field can be catastrophic.

Uneven heating during either debinding or sintering can lead to internal stresses, warping the component or compromising its structural integrity.

Making the Right Choice for Your Goal

To maximize the quality of your beta-TCP ceramics, you must tailor the furnace cycle to your specific objectives.

- If your primary focus is Purity and Bioactivity: Prioritize a slow, controlled ramp-up during the 600°C debinding phase to ensure absolute removal of all organic residues without damaging the pore structure.

- If your primary focus is Mechanical Strength: Ensure the furnace maintains the peak temperature (1000°C–1120°C) precisely to drive complete solid-phase sintering and optimal particle fusion.

Success lies in balancing the gentle removal of the temporary binder with the aggressive heat required to forge a permanent ceramic bond.

Summary Table:

| Process Phase | Temperature Range | Primary Function | Outcome |

|---|---|---|---|

| Debinding | ~600°C | Remove organic resins/binders | Clean, porous green body |

| Sintering | 1000°C – 1120°C | Solid-phase particle fusion | Dense, cohesive ceramic matrix |

| Structural Change | N/A | ~21% linear shrinkage | Final mechanical strength |

| Bioactivation | Peak Temps | Micropore development | Functional bioactivity |

Elevate Your Bioceramic Engineering with KINTEK

Precision thermal control is non-negotiable for the delicate metamorphosis of 3D-printed beta-TCP. KINTEK provides industry-leading high-temperature solutions—including Muffle, Tube, Vacuum, and CVD systems—engineered to deliver the uniform thermal fields and slow heating rates essential for defect-free sintering.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique lab requirements. Ensure the purity, strength, and bioactivity of your ceramic scaffolds today.

Contact Our Experts for a Custom Solution

Visual Guide

References

- Thomas Wojcik, Jean‐Christophe Hornez. Engineering Precise Interconnected Porosity in β-Tricalcium Phosphate (β-TCP) Matrices by Means of Top–Down Digital Light Processing. DOI: 10.3390/biomedicines12040736

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a laboratory high-temperature box furnace essential for komatiite glass? Achieve 1530°C Precision

- What is the significance of high-temperature furnace equipment in electrode testing? Ensure Industrial Peak Performance

- What role does a high-temperature muffle furnace play in the preparation of acid-activated clay? Key Thermal Mechanisms

- How does an industrial electric box furnace maintain sample alignment? Ensure Precision in High-Throughput Calcination

- Why are muffle furnaces important in laboratories? Essential for Contamination-Free High-Temperature Processing

- Why is temperature range important when selecting a muffle furnace? Ensure Process Success and Equipment Longevity

- What is the technical role of a muffle furnace in dyeing sludge ash preparation? Optimize Pozzolanic Activation

- What is the function of a high-temperature box resistance furnace? Optimize Hierarchical Zeolite Synthesis