In any serious laboratory, a muffle furnace is essential because it provides an environment for extremely high-temperature work that is simultaneously precise and free from contamination. This unique capability is critical for processes like determining the ash content of a sample, performing metallurgical analysis, or heat-treating materials, where accuracy and purity are non-negotiable.

The core value of a muffle furnace is not just its ability to generate intense heat, but its design that isolates the material being tested. This separation from the heating elements is what guarantees that results are accurate and material transformations are pure.

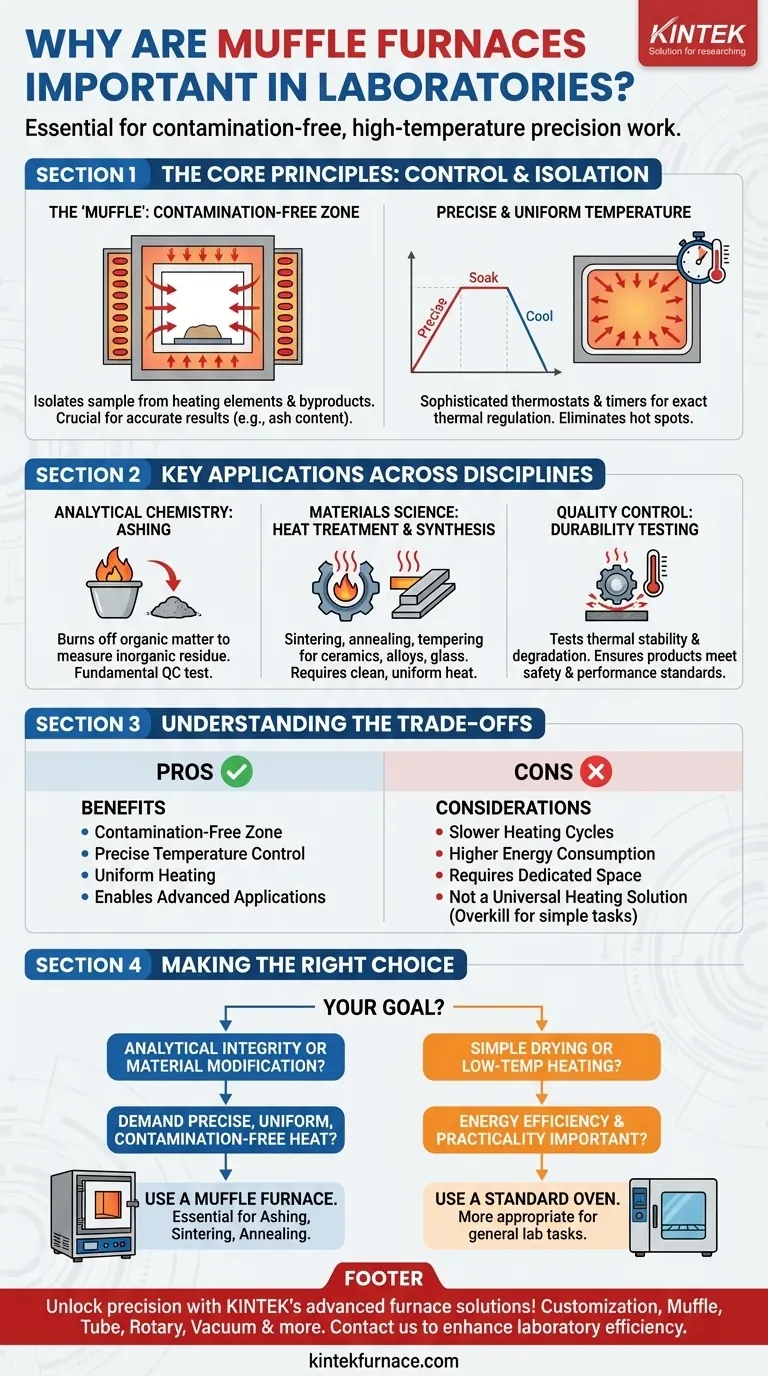

The Core Principles: Control and Isolation

A muffle furnace's importance comes from two fundamental design principles that separate it from a standard oven or kiln.

The 'Muffle': Guaranteeing a Contamination-Free Zone

The defining feature is the "muffle"—an inner chamber, typically made of high-temperature ceramic, that contains the sample.

The heating elements are on the outside of this chamber. This means the material being heated never comes into contact with combustion byproducts or oxidizing elements, which would contaminate the sample and invalidate results.

This isolation is indispensable for analytical procedures like ash content determination, where the goal is to measure only the inorganic residue of a sample after complete combustion.

Achieving Precise and Uniform Temperature

Muffle furnaces are engineered for superior thermal regulation. They are equipped with sophisticated thermostats and timers that allow operators to execute precise heating profiles.

This includes ramping up to a specific temperature, holding it for an exact duration (a "soak"), and cooling down at a controlled rate. This level of control is vital for processes like annealing metals, where the wrong temperature profile can ruin the material.

The enclosed, insulated design also ensures uniform heating, eliminating hot spots and providing consistent results for every sample, every time.

Key Applications Across Disciplines

The combination of clean, controlled heat makes the muffle furnace a cornerstone instrument in research, development, and quality control.

For Analytical Chemistry: Ashing

Ashing is the process of burning off all organic matter in a sample to precisely measure the weight of the remaining inorganic components (the ash).

This is a fundamental quality control test in industries from food science to mining. The muffle furnace ensures that the only thing being weighed at the end is the sample's true ash content, with no added contaminants.

For Materials Science: Heat Treatment and Synthesis

Developing new materials like ceramics, advanced alloys, and glass requires exact thermal processing.

A muffle furnace is used for sintering (fusing powdered materials into a solid mass), annealing (softening metals to improve ductility), and tempering (toughening steel). Each of these processes depends on the clean, uniform, and precisely controlled heat that only a muffle furnace can provide.

For Quality Control: Durability Testing

Manufacturers must understand how their products behave under extreme conditions.

Muffle furnaces are used to test the thermal stability of polymers, plastics, and coatings. By subjecting materials to intense heat in a controlled environment, labs can analyze degradation, determine failure points, and ensure products meet safety and performance standards.

Understanding the Trade-offs

While indispensable, a muffle furnace is a specialized tool with specific operational considerations.

Slower Heating Cycles

Because the heat is transferred indirectly to the sample through the muffle chamber, the ramp-up and cool-down times can be significantly longer than with direct-heating methods. This can affect laboratory throughput for high-volume testing.

Energy Consumption and Space

These are robust, heavily insulated machines that consume a considerable amount of energy to reach and maintain high temperatures. They also require dedicated, well-ventilated space, unlike a small benchtop oven.

Not a Universal Heating Solution

For simple applications like drying glassware or warming reagents to moderate temperatures, a muffle furnace is overkill. A standard laboratory oven is far more energy-efficient and appropriate for tasks that do not require extreme heat or a perfectly isolated environment.

Making the Right Choice for Your Goal

Selecting the correct heating instrument is critical for efficiency and accuracy. Your decision should be guided by the specific requirements of your procedure.

- If your primary focus is analytical integrity: Use a muffle furnace for any process, like ash testing, where sample contamination would invalidate the results.

- If your primary focus is modifying material properties: A muffle furnace is essential for heat treatments like annealing or sintering that demand precise and uniform temperature profiles.

- If your primary focus is simple drying or low-temperature heating: A standard laboratory oven is the more energy-efficient and practical choice.

Ultimately, understanding when to deploy a muffle furnace is key to ensuring the accuracy and reliability of your high-temperature laboratory work.

Summary Table:

| Feature | Benefit |

|---|---|

| Contamination-Free Zone | Isolates samples from heating elements for pure results |

| Precise Temperature Control | Enables accurate heating profiles for consistent outcomes |

| Uniform Heating | Eliminates hot spots, ensuring reliability across samples |

| Key Applications | Ashing, sintering, annealing, and durability testing |

| Considerations | Slower heating cycles, higher energy use, not for low-temp tasks |

Unlock precision in your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering contamination-free, controlled heating for applications like ashing and material synthesis. Contact us today to enhance your laboratory's efficiency and accuracy!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure