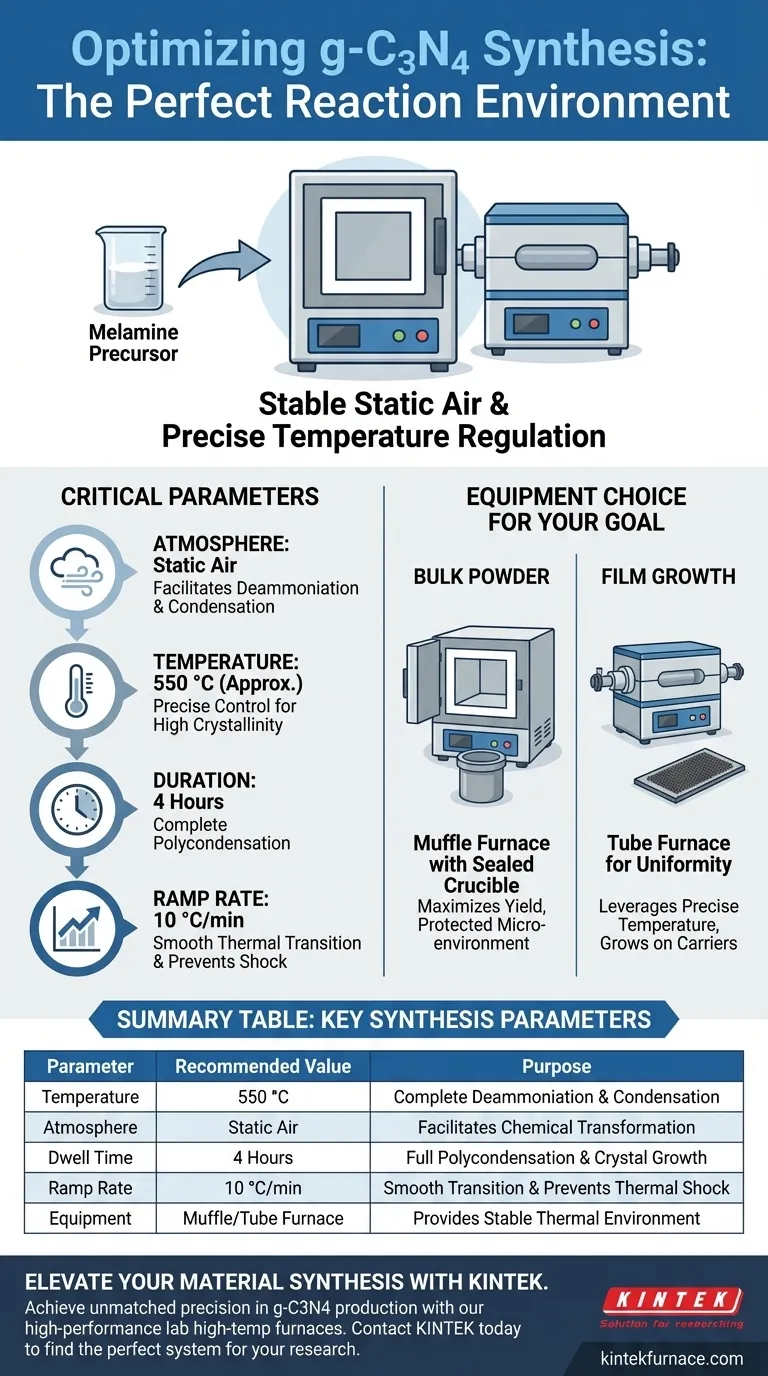

To successfully synthesize graphitic carbon nitride (g-C3N4), a muffle or tube furnace must provide a stable static air environment coupled with rigorous temperature regulation. Specifically, the system must maintain a temperature of approximately 550 °C for a duration of 4 hours to drive the deammoniation and condensation of melamine precursors.

The quality of g-C3N4 depends heavily on the stability of the thermal environment. A consistent static air atmosphere permits the complete transformation of monomers into a two-dimensional layered framework, while precise temperature control ensures high crystallinity.

The Critical Reaction Parameters

The Necessity of Static Air

For the polymerization process to occur correctly, the reaction chamber must maintain a static air environment.

This atmosphere is essential for facilitating the chemical changes required to convert melamine into graphitic carbon nitride. It supports the deammoniation process, where ammonia is released, allowing the carbon nitride structure to condense effectively.

Precise Temperature Control

The furnace must be capable of reaching and holding a target temperature of 550 °C with high accuracy.

Fluctuations in temperature can disrupt the formation of the crystal lattice. A steady thermal hold ensures the precursor material is fully converted, resulting in a chemically stable and structurally sound product.

The Role of Reaction Duration

Maintaining the target temperature for a specific period, typically 4 hours, is non-negotiable.

This duration allows sufficient time for the polycondensation reaction to reach completion. Cutting this time short may leave unreacted monomers, while extending it unnecessarily could degrade the material.

Controlling the Heating Trajectory

The Importance of Ramp Rate

Beyond the final temperature, the speed at which the furnace heats up is critical. A controlled ramp rate, such as 10 °C/min, is recommended.

This gradual increase in heat guides the smooth thermal polycondensation of the melamine molecules. It prevents thermal shock and ensures the material evolves uniformly from a monomeric state to a polymeric structure.

Formation of Crystalline Structure

The combination of the correct ramp rate and sustained heat creates a high-crystallinity structure.

Whether synthesized in bulk or grown on carriers like carbon nanofibers, this precise thermal history ensures the final g-C3N4 layer is structurally regular and robust.

Understanding the Trade-offs

Crucible Sealing vs. Atmosphere

In a muffle furnace, the precursor is often placed within a sealed crucible.

While the general environment is static air, the crucible creates a micro-environment that prevents rapid loss of volatile intermediates. If the crucible is not sealed properly, the yield may decrease; if sealed too tightly without pressure release, safety issues or incomplete reactions could occur.

Temperature Sensitivity

While 550 °C is the standard optimization, supplementary data suggests effective synthesis can occur around 520 °C.

Lower temperatures may result in incomplete polymerization, leading to defects in the graphitic sheet. Conversely, significantly exceeding 550 °C runs the risk of thermally decomposing the graphitic carbon nitride structure itself.

Making the Right Choice for Your Goal

When selecting your equipment and parameters, align them with your specific synthesis targets:

- If your primary focus is bulk powder synthesis: Use a muffle furnace with a sealed crucible to maximize yield and ensure a protected micro-environment during the 4-hour dwell time.

- If your primary focus is growing films on carriers: Use a tube furnace to leverage its precise temperature uniformity, ensuring the g-C3N4 layer grows securely on substrates like carbon nanofibers.

Success in g-C3N4 synthesis is defined not just by reaching 550 °C, but by the stability and precision of the thermal path you take to get there.

Summary Table:

| Parameter | Recommended Value | Purpose in g-C3N4 Synthesis |

|---|---|---|

| Temperature | 550 °C | Ensures complete deammoniation and condensation |

| Atmosphere | Static Air | Facilitates necessary chemical transformation of monomers |

| Dwell Time | 4 Hours | Allows for full polycondensation and crystal growth |

| Ramp Rate | 10 °C/min | Guides smooth transition and prevents thermal shock |

| Equipment | Muffle/Tube Furnace | Provides the stable thermal environment required |

Elevate Your Material Synthesis with KINTEK

Achieve unmatched precision in your g-C3N4 production. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of thermal polymerization. Whether you are producing bulk powders or advanced thin films on carbon nanofibers, our customizable lab high-temp furnaces ensure the stable static air environment and precise temperature control your research deserves.

Ready to optimize your synthesis results? Contact KINTEK today to find the perfect furnace for your laboratory.

Visual Guide

References

- Riccardo Dettori, Pier Carlo Ricci. Sustainable Photocatalysis with Phenyl-Modified g-C3N4/TiO2 Polymer Hybrids: A Combined Computational and Experimental Investigation. DOI: 10.3390/polym17101331

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary uses of a box furnace? Unlock Precise Heat Treatment for Your Materials

- How to calibrate a muffle furnace? Ensure Precise Temperature Control for Your Lab

- What is a box type resistance furnace and its core advantages? Essential for Precise, Uniform Heating in Labs

- How does a muffle furnace with a weighing system benefit biochar research? Gain Real-Time Pyrolysis Insights

- How does the muffle design contribute to furnace performance? Enhance Purity, Uniformity, and Efficiency

- How long does it take for a muffle furnace to reach maximum temperature? Optimize Your Lab's Heating Efficiency

- How does a vacuum furnace differ from a muffle furnace in terms of operation? Choose the Right Furnace for Your Lab

- What are the key features of box furnaces? Versatile Thermal Solutions for Labs and Industry