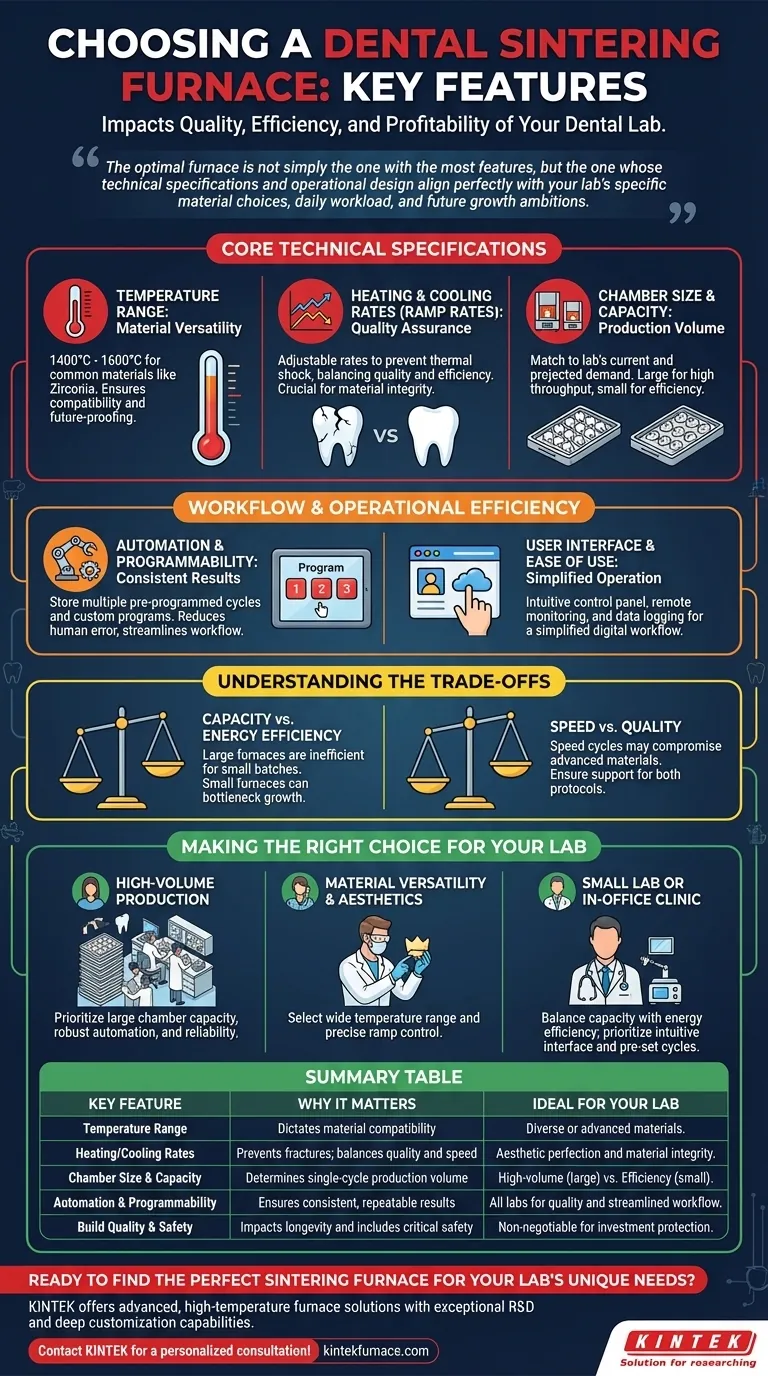

Selecting the right dental sintering furnace is a critical decision that directly impacts the quality, efficiency, and profitability of a dental lab. The key features to consider are the furnace's temperature range to ensure material compatibility, its chamber size and capacity to match production volume, its control over heating and cooling rates for quality assurance, and its automation and programming capabilities to guarantee consistent, repeatable results.

The optimal furnace is not simply the one with the most features, but the one whose technical specifications and operational design align perfectly with your lab's specific material choices, daily workload, and future growth ambitions.

Core Technical Specifications Explained

Choosing a furnace begins with understanding the fundamental technical capabilities that define its performance and versatility.

Temperature Range: The Key to Material Versatility

The furnace's temperature range dictates which materials you can process. A wider range offers greater flexibility to adopt new materials as they become available.

For common materials like zirconia, a maximum temperature between 1400°C and 1600°C is ideal. Verifying that a furnace can reliably reach and hold the temperatures required for your specific materials is the first step in your evaluation.

Heating and Cooling Rates (Ramp Rates)

The ability to precisely control the rate of temperature change—known as the ramp rate—is crucial for quality. Gradual heating and cooling prevent thermal shock, which can cause fractures or internal stress in restorations.

Furnaces with adjustable ramp rates allow you to fine-tune cycles for specific materials, balancing the need for a high-quality result with the desire for workflow efficiency.

Chamber Size and Capacity

The internal chamber size determines how many restorations you can sinter in a single cycle. This feature should be chosen based on your lab's current and projected production requirements.

A larger capacity increases throughput for high-volume labs, while a smaller furnace may be more energy-efficient and suitable for practices with lower or more sporadic demand. Ensure the chamber allows for adequate spacing between units to promote even heating.

Workflow and Operational Efficiency

Beyond raw specifications, a furnace must integrate smoothly into your daily operations, enhancing productivity and reducing the chance for error.

Automation and Programmability

Automation is the key to achieving consistent, predictable results. Look for furnaces with the ability to store multiple programmable cycles.

Pre-programmed cycles for common materials streamline the workflow for technicians, while the option to create and save custom programs is essential for specialized cases or new materials. This reduces the risk of human error and ensures every restoration meets the same high standard.

User Interface and Ease of Use

A furnace with an intuitive control panel and clear display simplifies operation and reduces the learning curve for staff.

Modern furnaces may also offer connectivity features for data logging, remote monitoring, or integration with your existing CAD/CAM systems, further centralizing and simplifying your digital workflow.

Understanding the Trade-offs

An objective evaluation requires acknowledging the inherent compromises in any equipment choice.

Capacity vs. Energy Efficiency

A large-capacity furnace is a powerful asset for a high-production lab, but it can be highly inefficient if you consistently run small batches. The energy required to heat a large, empty chamber is wasted. Conversely, a small furnace will create a significant bottleneck if your production volume grows.

Speed vs. Quality

Many modern furnaces offer "speed" sintering cycles that dramatically reduce processing time. While valuable for urgent cases, these rapid cycles can sometimes compromise the final translucency or structural integrity of certain advanced zirconia materials. Your furnace should capably support both standard and accelerated protocols.

Build Quality and Essential Safety

A furnace is a long-term investment, making build quality and durability paramount for achieving a good return. The type of heating elements used is a key factor; silicon carbide elements are often preferred for their longevity and performance with zirconia.

Crucially, the furnace must include non-negotiable safety features. Look for over-temperature protection and automatic shut-off systems to protect your staff, your equipment, and your facility.

Making the Right Choice for Your Lab

Your decision should be guided by a clear understanding of your lab's primary goals.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber capacity, robust automation, and a proven record of reliability to maximize throughput.

- If your primary focus is material versatility and custom aesthetics: Select a furnace with a wide temperature range and precise, programmable control over heating and cooling ramp rates.

- If your primary focus is a smaller lab or in-office clinic: Balance capacity with energy efficiency and choose a model with an intuitive interface and reliable pre-programmed cycles to shorten the learning curve.

Ultimately, a well-chosen furnace is a foundational asset that enhances both the quality of your restorations and the efficiency of your entire digital workflow.

Summary Table:

| Key Feature | Why It Matters | Ideal for Your Lab |

|---|---|---|

| Temperature Range | Dictates material compatibility (e.g., zirconia up to 1600°C). | If you plan to use diverse or advanced materials. |

| Heating/Cooling Rates | Prevents fractures; balances quality and speed. | For labs prioritizing aesthetic perfection and material integrity. |

| Chamber Size & Capacity | Determines single-cycle production volume. | High-volume labs need larger chambers; smaller labs value efficiency. |

| Automation & Programmability | Ensures consistent, repeatable results with minimal error. | Essential for all labs to guarantee quality and streamline workflow. |

| Build Quality & Safety | Impacts longevity and includes critical over-temperature protection. | A non-negotiable for protecting your investment and ensuring safety. |

Ready to find the perfect sintering furnace for your lab's unique needs?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions. Our product line, including high-precision dental sintering furnaces, is complemented by strong deep customization capabilities to precisely meet your lab's specific material requirements, production volume, and workflow.

Let us help you enhance the quality of your restorations and the efficiency of your digital workflow. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations