The primary role of a high-precision thermocouple pair is to provide accurate, real-time feedback that keeps the Aluminum 6063 melt within a strict processing window. In a resistance furnace, where thermal inertia can be high, these sensors prevent the temperature from drifting into ranges that chemically degrade the alloy or compromise its physical flow.

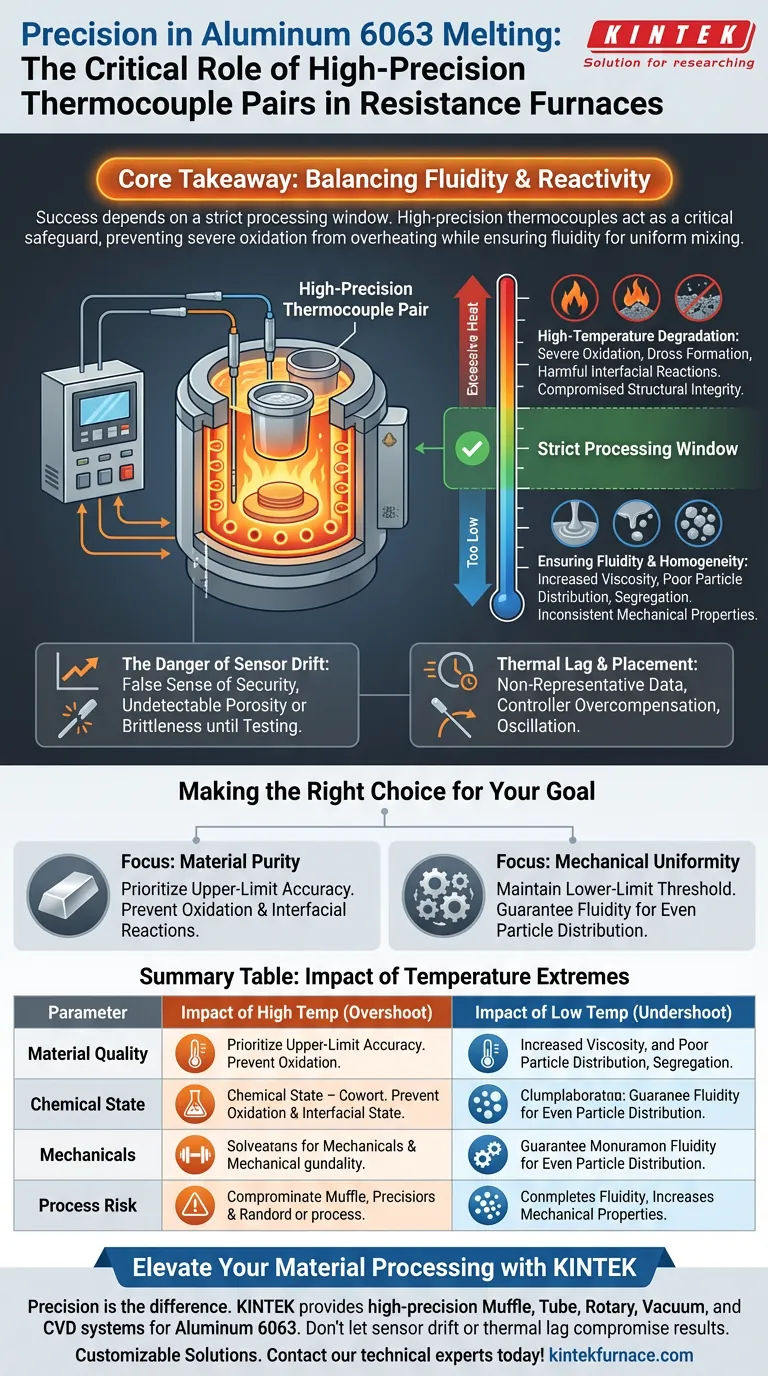

Core Takeaway Success in melting Aluminum 6063 relies on balancing fluidity against chemical reactivity. A high-precision thermocouple pair acts as the critical safeguard, preventing the severe oxidation caused by overheating while ensuring the metal remains fluid enough for uniform mixing and particle distribution.

The Criticality of the Thermal Window

Preventing High-Temperature Degradation

The upper limit of your temperature range is defined by chemical stability. If the thermocouple reports inaccurate data, the furnace may unknowingly overshoot the target temperature.

Excessive heat triggers severe oxidation, creating dross that ruins the material quality. Furthermore, in the context of aluminum matrix composites, overheating leads to harmful interfacial reactions between the aluminum alloy and reinforcement particles, compromising the structural integrity of the final product.

Ensuring Fluidity and Homogeneity

The lower limit of your processing window is defined by viscosity. Accurate low-end monitoring is required to ensure the melt retains sufficient fluidity.

If the temperature drops too low due to sensor error, the viscosity of the aluminum increases significantly. This lack of fluidity prevents the uniform distribution of particles during mixing, leading to segregation and inconsistent mechanical properties in the solidified alloy.

Understanding the Risks and Trade-offs

The Danger of Sensor Drift

Even high-precision thermocouples can drift over time due to thermal cycling and chemical attack from the furnace environment.

Reliance on a single sensor or an uncalibrated pair can create a false sense of security. If the "precision" reading drifts just a few degrees outside the ideal window, you may encounter porosity or brittleness that is undetectable until mechanical testing.

Thermal Lag and Placement

A resistance furnace provides a stable thermal field, but it does not change temperature instantly.

There is often a delay between the energy input and the melt temperature change. If the thermocouple pair is positioned poorly—such as too close to the heating elements or too far from the crucible center—it will provide non-representative data, leading the controller to overcompensate and oscillate around the setpoint.

Making the Right Choice for Your Goal

To maximize the effectiveness of your melting process, align your thermal control strategy with your specific quality targets:

- If your primary focus is Material Purity: Prioritize the upper-limit accuracy of your thermocouple pair to prevent oxidation and interfacial reactions.

- If your primary focus is Mechanical Uniformity: Ensure the thermocouple pair is calibrated to maintain the lower temperature threshold, guaranteeing the fluidity needed for even particle distribution.

Precision monitoring is the only way to transform raw alloy potential into consistent, high-performance material properties.

Summary Table:

| Parameter | Impact of High Temperature (Overshoot) | Impact of Low Temperature (Undershoot) |

|---|---|---|

| Material Quality | Severe oxidation and dross formation | Increased viscosity and poor fluidity |

| Chemical State | Harmful interfacial reactions | Potential particle segregation |

| Mechanicals | Compromised structural integrity | Inconsistent distribution of reinforcements |

| Process Risk | Chemical degradation of the alloy | Non-uniform mixing and solidification |

Elevate Your Material Processing with KINTEK

Precision is the difference between a high-performance alloy and a wasted batch. Backed by expert R&D and world-class manufacturing, KINTEK provides high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous thermal demands of Aluminum 6063 processing.

Our lab high-temperature furnaces are fully customizable to your unique needs, ensuring you achieve the exact thermal window required for superior homogeneity and purity. Don't let sensor drift or thermal lag compromise your results.

Contact our technical experts today to find the perfect furnace solution for your laboratory or industrial application!

Visual Guide

References

- Ahmed hewidy, Ibrahim Sabry. MECHANICAL AND TRIBOLOGICAL CHARACTERISTICS OF STIR-CASTING Al2O3-SiC-Gr/Al6063 HYBRID COMPOSITE. DOI: 10.21608/jest.2024.334761

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How do alumina ceramic tubes improve temperature control and safety in high-temperature furnaces? Enhance Precision and Safety Up to 1800°C

- What future developments are anticipated for high temperature heating elements? Discover Tailored Solutions for Demanding Processes

- What role does an industrial K-type armored thermocouple play in annealing? Real-time Embedded Process Validation

- What are the properties and applications of Nickel-Chromium (NiCr) alloy in heating elements? Discover High-Temp Reliability

- What is the process by which a heating element converts electrical energy into heat? Discover Joule Heating Essentials

- What are the applications of molybdenum disilicide heating elements? Achieve Extreme Heat Stability for Industrial Processes

- How is temperature controlled in resistance heating? Master Precise Heat Management for Your Lab

- What are some future innovations in high-temperature heating elements? Explore Smart, Efficient Solutions