In short, molybdenum disilicide (MoSi2) heating elements are used in high-temperature electric furnaces for industrial production and laboratory research. Their primary applications are found in processes requiring stable, extreme heat (up to 1850°C) in an air or oxidizing atmosphere, such as glass manufacturing, ceramic sintering, steel heat treatment, and electronics fabrication.

The decision to use MoSi2 elements goes beyond simply needing high heat. It is a strategic choice for applications demanding exceptional temperature stability, long operational life, and reliable performance in oxidizing environments where most other metallic elements would quickly degrade.

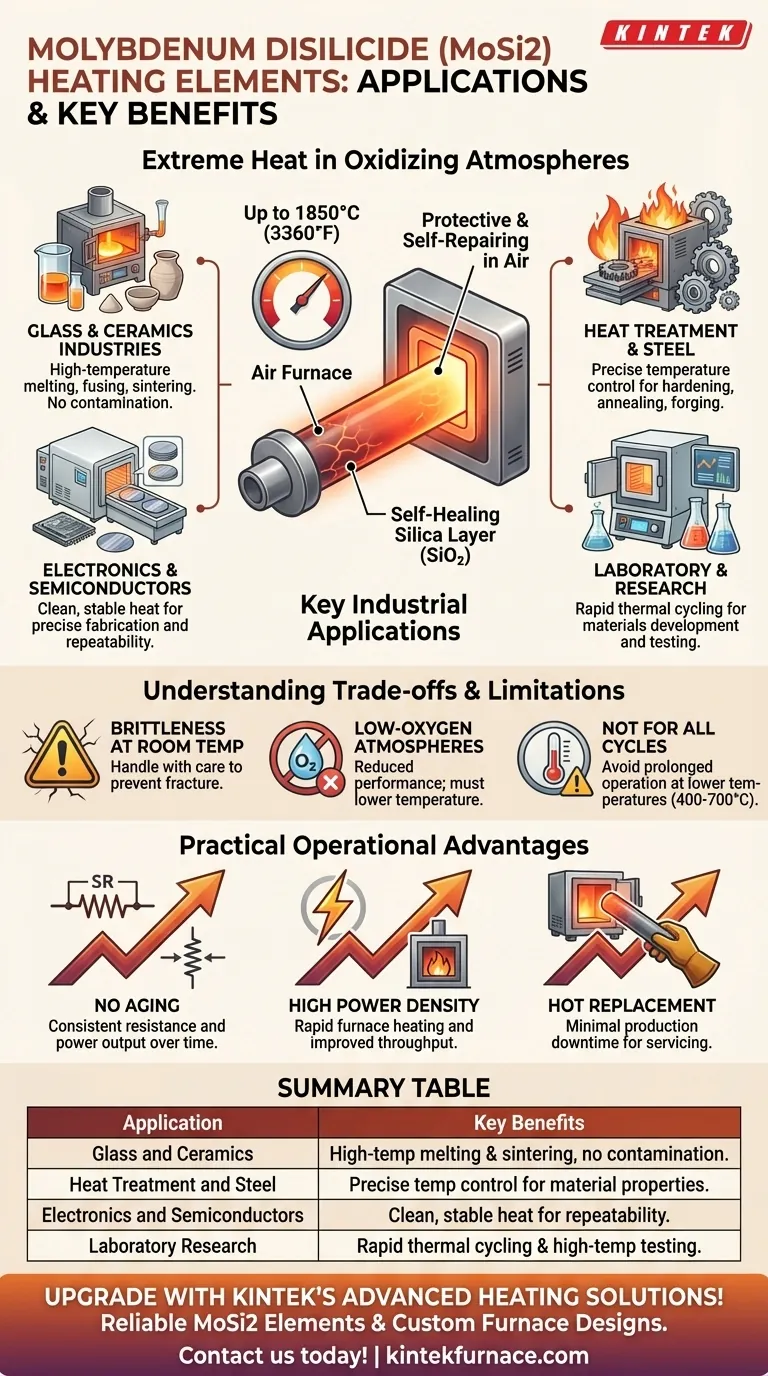

The Defining Characteristic: Extreme Heat in Oxidizing Atmospheres

The fundamental value of MoSi2 elements comes from their unique ability to not just survive, but thrive at extreme temperatures in the presence of oxygen. This is due to a combination of material properties.

Reaching Up to 1850°C (3360°F)

MoSi2 elements have the highest operating temperatures among common metallic and ceramic heating elements. This makes them the default choice for processes that begin where others fail, typically above 1600°C.

The Self-Healing Silica Layer

When heated in an oxidizing atmosphere (like air), MoSi2 forms a thin, protective surface layer of pure silica (SiO₂), which is essentially glass. This passivation layer prevents the underlying material from further oxidation, enabling its long life at high temperatures. If the layer is scratched or damaged, it will "heal" itself as long as oxygen is present.

Key Industrial Applications

The unique properties of MoSi2 make it indispensable in several key industries where precise, high, and stable heat is a non-negotiable requirement.

Glass and Ceramics Industries

These processes require extremely high temperatures for melting, fusing, and sintering materials. MoSi2 elements provide the necessary heat for producing high-purity glass and firing advanced ceramic components without introducing contaminants.

Heat Treatment and Steel Production

Metallurgical processes like hardening, annealing, and forging require precise temperature control to achieve specific material properties. The stability and high-temperature capability of MoSi2 are critical for these applications in furnace environments.

Electronics and Semiconductor Manufacturing

Processes like diffusion furnaces in semiconductor fabrication demand an exceptionally clean and stable high-temperature environment. The reliable and consistent heat output of MoSi2 elements ensures process repeatability.

Laboratory and Research Furnaces

Researchers value MoSi2 for its rapid thermal cycling capability, allowing furnaces to heat up and cool down quickly without element degradation. This, combined with its high temperature range, makes it ideal for developing new materials and testing under extreme conditions.

Understanding the Trade-offs and Limitations

While powerful, MoSi2 elements are not a universal solution. Understanding their limitations is critical for proper application and avoiding costly failures.

Brittleness at Room Temperature

Like many ceramics, MoSi2 is brittle at ambient temperatures. The elements must be handled with care during shipping, installation, and furnace maintenance to prevent cracking or fracture.

Reduced Performance in Low-Oxygen Atmospheres

The protective silica layer is the key to MoSi2's survival. In low-oxygen, inert, or reducing atmospheres, this layer cannot form or be maintained. This forces a significant reduction in the maximum operating temperature to prevent catastrophic element failure, a phenomenon known as "pesting."

Not Suitable for All Furnace Cycles

While excellent for rapid cycling, prolonged operation at lower temperatures (between 400°C and 700°C) in oxidizing atmospheres can sometimes lead to accelerated degradation. The elements are designed to run hot.

Practical Advantages in Operation

Beyond high heat, MoSi2 elements offer significant operational benefits that impact furnace uptime and maintenance costs.

No Aging and Stable Resistance

Unlike many other element types, MoSi2 elements do not age, meaning their electrical resistance does not change over time. This ensures consistent power output and allows new elements to be connected in series with old ones without issue.

High Power Density

MoSi2 elements support very high watt loadings. This allows for the design of furnaces that can heat up very rapidly, improving process throughput.

Ease of Replacement

Many MoSi2 element designs allow for individual replacement while the furnace remains hot. This dramatically reduces production downtime compared to elements that require a full furnace cooldown for servicing.

Making the Right Choice for Your Application

Selecting the correct heating element requires matching the material's strengths to your process goals.

- If your primary focus is maximum temperature in an air furnace: MoSi2 is the industry-leading choice, capable of reliably operating at temperatures up to 1850°C.

- If your primary focus is process stability and long-term consistency: The non-aging characteristic of MoSi2 ensures a stable heat source and simplifies maintenance over the furnace's life.

- If you are operating in a low-oxygen or reducing atmosphere: You must either lower the maximum operating temperature significantly or specify an alternative element, such as pure molybdenum or silicon carbide.

By understanding these core principles, you can confidently specify Molybdenum Disilicide for the demanding applications where it excels and avoid misapplication where it may fail.

Summary Table:

| Application | Key Benefits |

|---|---|

| Glass and Ceramics | High-temperature melting and sintering, no contamination |

| Heat Treatment and Steel | Precise temperature control for material properties |

| Electronics and Semiconductors | Clean, stable heat for process repeatability |

| Laboratory Research | Rapid thermal cycling and high-temperature testing |

Upgrade your high-temperature processes with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom furnace designs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is tailored to meet your unique experimental needs with deep customization. Ensure superior performance and efficiency—contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity