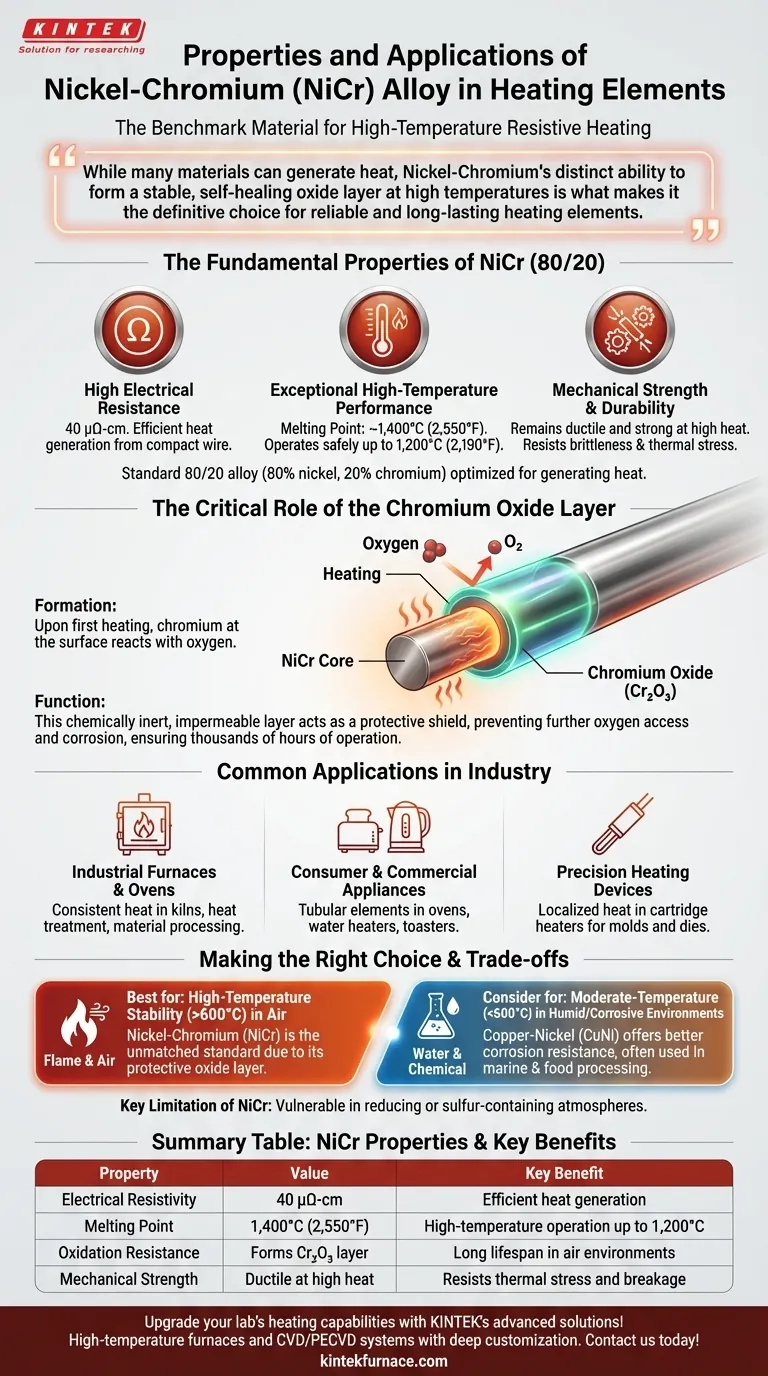

In the world of resistive heating, Nickel-Chromium (NiCr) alloy is the benchmark material for high-temperature applications. Its prominence stems from a unique combination of high electrical resistance, mechanical durability at extreme heat, and most importantly, an exceptional resistance to oxidation. This makes it the go-to choice for reliable heating elements in everything from industrial furnaces to household appliances.

While many materials can generate heat when electricity passes through them, Nickel-Chromium's distinct ability to form a stable, self-healing oxide layer at high temperatures is what makes it the definitive choice for reliable and long-lasting heating elements.

The Fundamental Properties of NiCr (80/20)

To understand why NiCr is so dominant, we must first examine its core characteristics. The standard 80/20 alloy (80% nickel, 20% chromium) offers a precise balance of properties optimized for generating heat.

High Electrical Resistance

A heating element works by converting electrical energy into heat through resistance (Joule heating). NiCr possesses a relatively high electrical resistivity of 40 μΩ-cm.

This high resistance allows a significant amount of heat to be generated from a physically compact and durable wire, making it ideal for designing efficient heating systems.

Exceptional High-Temperature Performance

NiCr alloy has a very high melting point of approximately 1,400°C (2,550°F).

This allows it to operate safely and continuously at temperatures up to 1,200°C (2,190°F) without degrading, a range where many other metals would fail.

Mechanical Strength and Durability

Even when glowing red-hot, NiCr wire remains ductile and strong. It resists becoming brittle after repeated cycles of heating and cooling.

This mechanical stability is critical for longevity, as it prevents the element from sagging, stretching, or breaking under thermal stress.

The Critical Role of the Chromium Oxide Layer

The single most important property of NiCr is not its resistance or melting point, but its behavior when exposed to air at high temperatures. This is the key to its long operational life.

How the Protective Layer Forms

When a NiCr element is heated for the first time, the chromium at the surface instantly reacts with oxygen in the atmosphere.

This reaction forms a thin, durable, and highly adherent outer layer of chromium oxide (Cr₂O₃).

Why This Layer is Essential for Longevity

The chromium oxide layer is an electrical insulator, but more importantly, it is chemically inert and impermeable to oxygen.

It effectively creates a protective shield that prevents the oxygen from reaching the nickel-chromium underneath. This "passivation" process stops further oxidation and corrosion, allowing the element to function for thousands of hours without burning out.

Common Applications in Industry

The reliability and performance of NiCr have made it a staple in a wide array of heating applications.

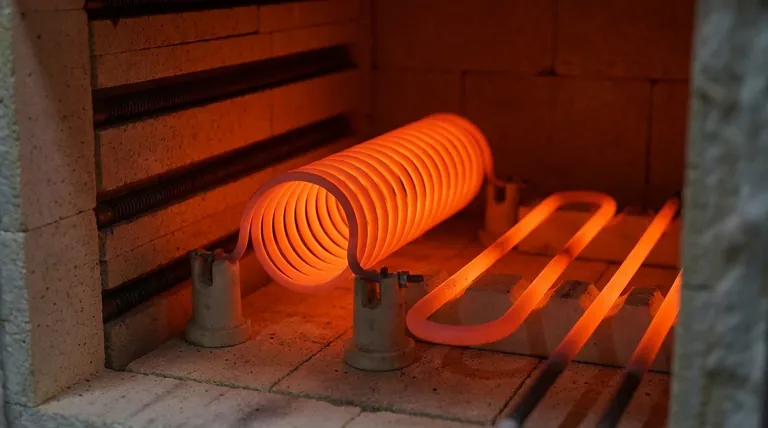

Industrial Furnaces and Ovens

In large-scale industrial furnaces used for heat treatment, kilns, and material processing, NiCr elements provide consistent and reliable heat in demanding environments.

Consumer and Commercial Appliances

You will find NiCr in tubular heating elements inside electric ovens, water heaters, and toasters. Its stability ensures safe and predictable performance over the appliance's lifespan.

Precision Heating Devices

For applications requiring localized and controlled heat, such as cartridge heaters used in molds and dies, NiCr offers the necessary precision and durability.

Understanding the Trade-offs

While NiCr is an excellent general-purpose heating alloy, no material is perfect for every situation. Understanding its limitations is key to making an informed decision.

When NiCr Is the Best Choice

NiCr excels in applications requiring stable, long-term heating in air at temperatures above 500°C. Its protective oxide layer provides unmatched performance in these conditions.

When Other Alloys Are Better: The Case for Copper-Nickel (CuNi)

For moderate-temperature applications (typically below 600°C) in humid or corrosive environments, a Copper-Nickel (CuNi) alloy may be superior.

While CuNi has a lower melting point, it offers better resistance to corrosion in moist settings where NiCr's oxide layer might be less effective. It is often found in marine and food processing equipment.

Key Limitations

The primary weakness of NiCr is its performance in certain atmospheres. Reducing atmospheres or those containing sulfur can attack the protective oxide layer, leading to premature failure.

Making the Right Choice for Your Application

Selecting the correct alloy requires aligning the material's properties with the operational environment and performance goals.

- If your primary focus is high-temperature stability (>600°C) in air: Nickel-Chromium is the unmatched standard due to its protective oxide layer.

- If your primary focus is moderate-temperature heating in corrosive or humid environments: A Copper-Nickel alloy will likely offer better longevity and performance.

- If your primary focus is extreme heat (>1200°C) or specific chemical atmospheres: You may need to explore more specialized materials like molybdenum disilicide or silicon carbide.

By understanding the fundamental properties that make these alloys work, you can select a material that ensures both operational efficiency and long-term reliability for your specific heating challenge.

Summary Table:

| Property | Value | Key Benefit |

|---|---|---|

| Electrical Resistivity | 40 μΩ-cm | Efficient heat generation in compact designs |

| Melting Point | 1,400°C (2,550°F) | High-temperature operation up to 1,200°C |

| Oxidation Resistance | Forms Cr₂O₃ layer | Long lifespan in air environments |

| Mechanical Strength | Ductile and strong at high heat | Resists thermal stress and breakage |

Upgrade your lab's heating capabilities with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our NiCr-based heating elements can optimize your processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance