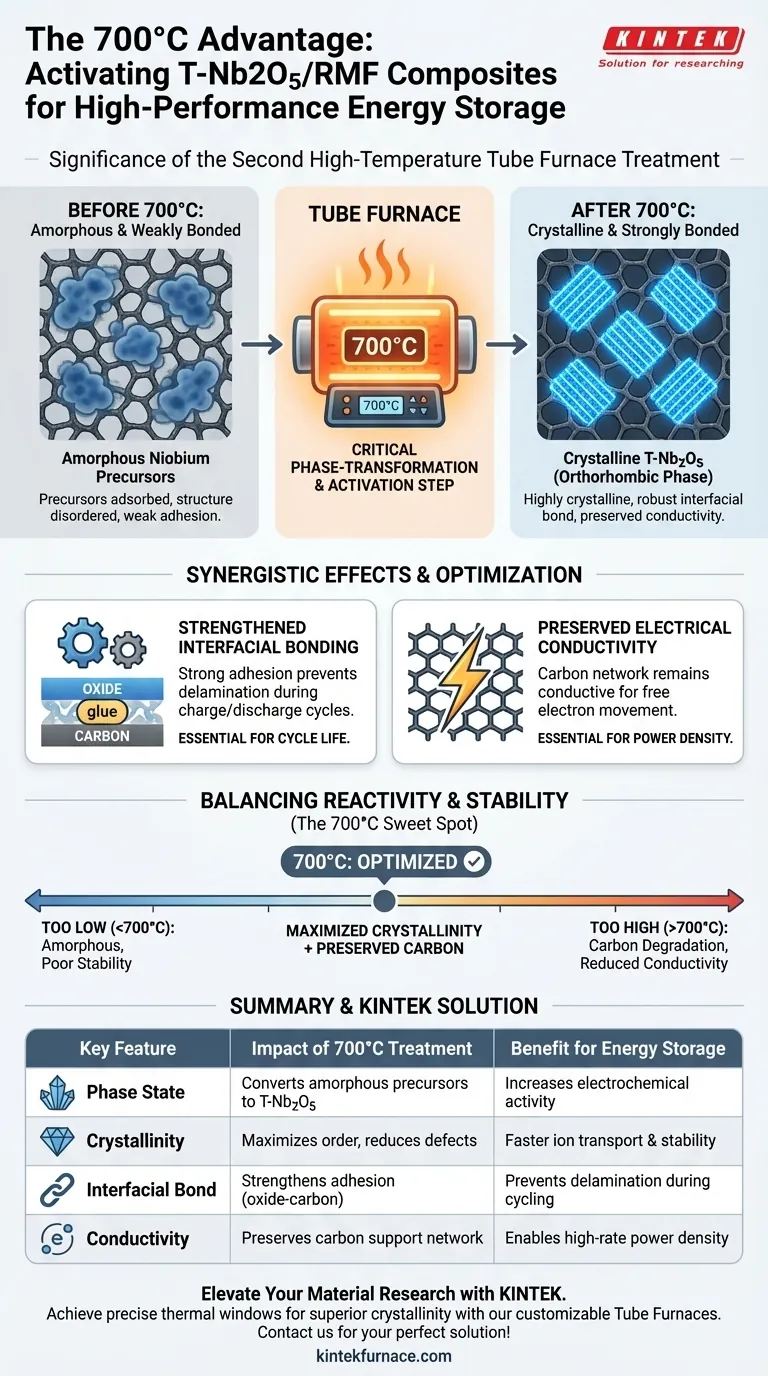

The significance of the second high-temperature tube furnace treatment at 700°C is that it acts as the primary crystallization and activation step. This process converts amorphous niobium precursors into the specific orthorhombic phase of niobium pentoxide (T-Nb2O5) while simultaneously creating a robust structural bond with the carbon support.

The 700°C treatment is not merely a drying step; it is a critical phase-transformation process that balances the formation of highly crystalline T-Nb2O5 with the preservation of the carbon support's electrical conductivity, directly unlocking high pseudocapacitive performance and long-term cycling stability.

The Mechanism of Phase Transformation

Creating the Orthorhombic Phase

The primary chemical objective of heating the composite to 700°C is to transform the niobium precursors.

These precursors, which are adsorbed within the carbon pores, are converted into the orthorhombic crystalline phase (T-Nb2O5). This specific crystal structure is essential for the material's electrochemical activity.

Enhancing Material Crystallinity

Beyond simple conversion, this high-temperature treatment significantly enhances the overall crystallinity of the material.

High crystallinity reduces internal defects within the metal oxide structure. This is crucial for facilitating efficient ion transport and ensuring the material performs reliably as an anode.

Synergistic Effects on the Composite Structure

Strengthening Interfacial Bonding

A critical physical change occurs at the boundary between the metal oxide and the carbon support.

The heat treatment strengthens the interfacial bonding between the T-Nb2O5 and the porous carbon matrix. This strong adhesion prevents the active material from detaching during the physical stress of charge/discharge cycles.

Preserving Electrical Conductivity

While high heat is used to crystallize the oxide, the process is tuned to protect the carbon support.

The 700°C treatment ensures the carbon retains its electrical conductivity. This conductive network is vital for allowing electrons to move freely through the composite, complementing the ion storage capabilities of the niobium oxide.

Understanding the Trade-offs

Balancing Reactivity and Stability

The selection of 700°C represents a precise optimization point for this composite material.

If the temperature were significantly lower, the niobium might remain amorphous or fail to reach the desired T-Nb2O5 phase, resulting in poor stability. Conversely, unchecked heating could degrade the carbon support or reduce its conductivity. The success of this material relies on hitting the specific thermal window where crystallinity is maximized without compromising the conductive carbon backbone.

Making the Right Choice for Your Goal

The 700°C treatment is the defining step for tailoring T-Nb2O5/RMF composites for high-performance energy storage.

- If your primary focus is Cycle Life: This treatment is essential because the strengthened interfacial bonding prevents material degradation and delamination over repeated uses.

- If your primary focus is Power Density: The preservation of the carbon's electrical conductivity ensures low resistance, allowing for rapid charge transfer and high pseudocapacitive rates.

By strictly adhering to the 700°C protocol, you ensure the creation of a robust, high-rate anode material that effectively leverages the strengths of both the metal oxide and the carbon support.

Summary Table:

| Key Feature | Impact of 700°C Treatment | Benefit for Energy Storage |

|---|---|---|

| Phase State | Converts amorphous precursors to T-Nb2O5 | Increases electrochemical activity |

| Crystallinity | Maximizes crystalline order while reducing defects | Faster ion transport & stability |

| Interfacial Bond | Strengthens adhesion between oxide and carbon | Prevents delamination during cycling |

| Conductivity | Preserves the carbon support's network | Enables high-rate power density |

Elevate Your Material Research with KINTEK

Precision heating is the backbone of advanced material synthesis. At KINTEK, we understand that achieving the exact thermal window for T-Nb2O5 crystallization requires uncompromising temperature uniformity and control.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems. Whether you are optimizing anode composites or developing next-generation catalysts, our lab high-temp furnaces are fully customizable to meet your unique research needs.

Ready to achieve superior crystallinity in your composites? Contact us today to find the perfect furnace solution!

Visual Guide

References

- Qi Chen, Licheng Ling. Enhanced Electrochemical Performance of Dual-Ion Batteries with T-Nb2O5/Nitrogen-Doped Three-Dimensional Porous Carbon Composites. DOI: 10.3390/molecules30020227

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a high-temperature tube furnace facilitate coal combustion simulation? Mastering Industrial R&D

- What safety features are typically included in vacuum tube furnaces? Essential Protection for High-Temp Labs

- What environmental applications do rotary tube furnaces have? Transform Waste into Value with Advanced Thermal Processing

- How to use a tubular furnace? Master Precise Temperature Control for Your Lab

- Why is the encapsulation of raw materials in a vacuum-sealed quartz tube necessary for crystal growth? Key to Purity

- Why is a tube furnace with high-purity Ar protection necessary for LiFePO4 calcination? Ensure Fe2+ Phase Purity

- What are the technical advantages of using a tube furnace for rice husk carbonization? Master Precise Synthesis

- Why is a high-precision tube furnace necessary for YIG thin films? Unlock Superior Magnetic Performance