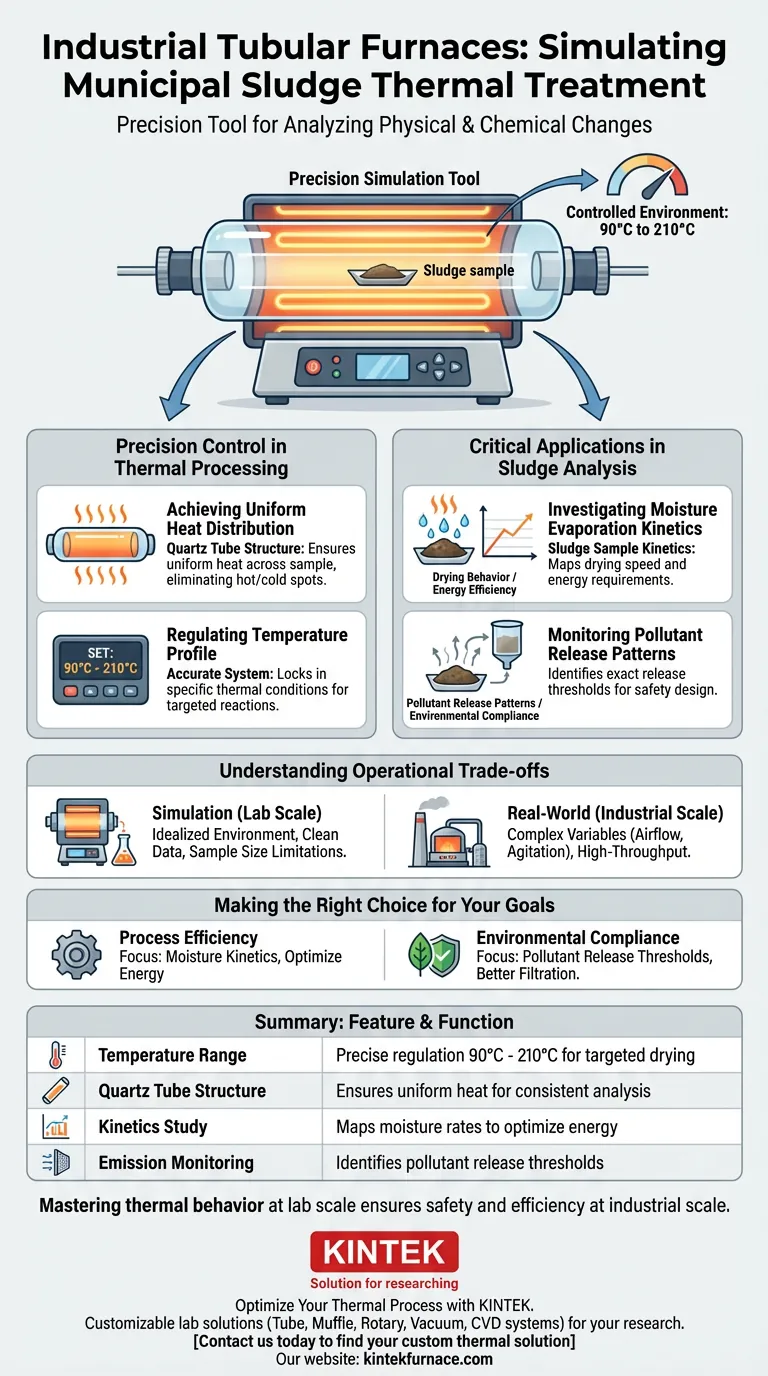

The primary role of an industrial tubular furnace in this context is to act as a precision simulation tool for the thermal processing of municipal sludge. It provides a controlled environment, typically ranging from 90°C to 210°C, allowing operators to treat sludge samples with uniform heat to analyze their physical and chemical changes.

The industrial tubular furnace serves as a laboratory benchmark for thermal treatment. By utilizing a quartz tube structure and precise temperature regulation, it allows researchers to accurately model how sludge behaves during drying and heating, specifically regarding moisture loss and pollutant emissions.

Precision Control in Thermal Processing

Achieving Uniform Heat Distribution

The core advantage of this furnace is its quartz tube structure. Unlike standard ovens that may have hot or cold spots, the tubular design ensures that heat is applied evenly across the entire sample. This uniformity is non-negotiable for scientific accuracy.

Regulating the Temperature Profile

The system utilizes an accurate temperature control system to maintain specific thermal conditions. The ability to lock in temperatures between 90°C and 210°C is critical because different chemical reactions and physical changes occur at very specific heat thresholds.

Critical Applications in Sludge Analysis

Investigating Moisture Evaporation Kinetics

One of the main functions of the furnace is to study drying behavior. By subjecting sludge to controlled heat, researchers can map out the kinetics of moisture evaporation. This data reveals how fast sludge dries and how much energy is required to reach a specific dryness level.

Monitoring Pollutant Release Patterns

Municipal sludge often contains volatile contaminants. The tubular furnace allows for the isolation and study of pollutant release patterns. Understanding at exactly what temperature specific pollutants are released helps in designing safer, more environmentally compliant full-scale treatment plants.

Understanding the Operational Trade-offs

Simulation vs. Real-World Complexity

While the tubular furnace is excellent for obtaining clean data, it represents an idealized environment. It eliminates the variables found in massive industrial kilns, such as uneven airflow or mechanical agitation.

Sample Size Limitations

This equipment is designed for investigating samples, not bulk processing. It is a diagnostic and research tool intended to optimize parameters, rather than a machine for high-throughput waste disposal.

Making the Right Choice for Your Goals

To maximize the value of an industrial tubular furnace, align its capabilities with your specific data requirements:

- If your primary focus is process efficiency: Use the furnace to determine the precise moisture evaporation kinetics, allowing you to optimize energy usage in larger drying systems.

- If your primary focus is environmental compliance: Use the temperature control to identify the exact thresholds where pollutants are released, helping you design better filtration and scrubbing protocols.

Mastering the thermal behavior of sludge at the laboratory scale is the most effective way to ensure safety and efficiency at the industrial scale.

Summary Table:

| Feature | Function in Sludge Treatment |

|---|---|

| Temperature Range | Precise regulation between 90°C and 210°C for targeted drying |

| Quartz Tube Structure | Ensures uniform heat distribution for consistent sample analysis |

| Kinetics Study | Maps moisture evaporation rates to optimize energy efficiency |

| Emission Monitoring | Identifies specific temperature thresholds for pollutant release |

Optimize Your Thermal Process with KINTEK

Ready to transform your sludge treatment research into industrial-scale success? Backed by expert R&D and manufacturing, KINTEK offers a wide range of customizable lab solutions—including Tube, Muffle, Rotary, Vacuum, and CVD systems—specifically designed to meet your unique high-temperature needs.

Our precision-engineered furnaces empower researchers to accurately model moisture kinetics and environmental impacts, ensuring your facility achieves peak efficiency and compliance.

Contact us today to find your custom thermal solution

Visual Guide

References

- Yun Xu, Heng Chen. Study on Drying of Municipal Sludge and Pollutants Release Characteristics. DOI: 10.3390/pr13010053

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How is the quartz tube furnace constructed for vacuum operations? Discover Key Design Elements for High-Temperature Vacuum Processing

- What is the future potential of fluidized bed vertical tube furnaces? Unlock Efficiency and Growth in Your Industry

- How does a tube furnace facilitate T5 and T6 heat treatment? Optimize Aluminum Alloy Strength and Hardness

- Why is a high-temperature tube furnace utilized for the pyrolysis of Sr2TiO4 precursor powders? Achieving High Purity

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- How does a Tube CVD furnace facilitate the in-situ synthesis of CNT/Cu composite powders? Achieve Superior Material Bonds

- What types of tube materials are available for tube furnaces and what are their temperature limits? Choose the Right Material for Your Lab

- What is a high temperature tube furnace? Achieve Precise Heat and Atmosphere Control