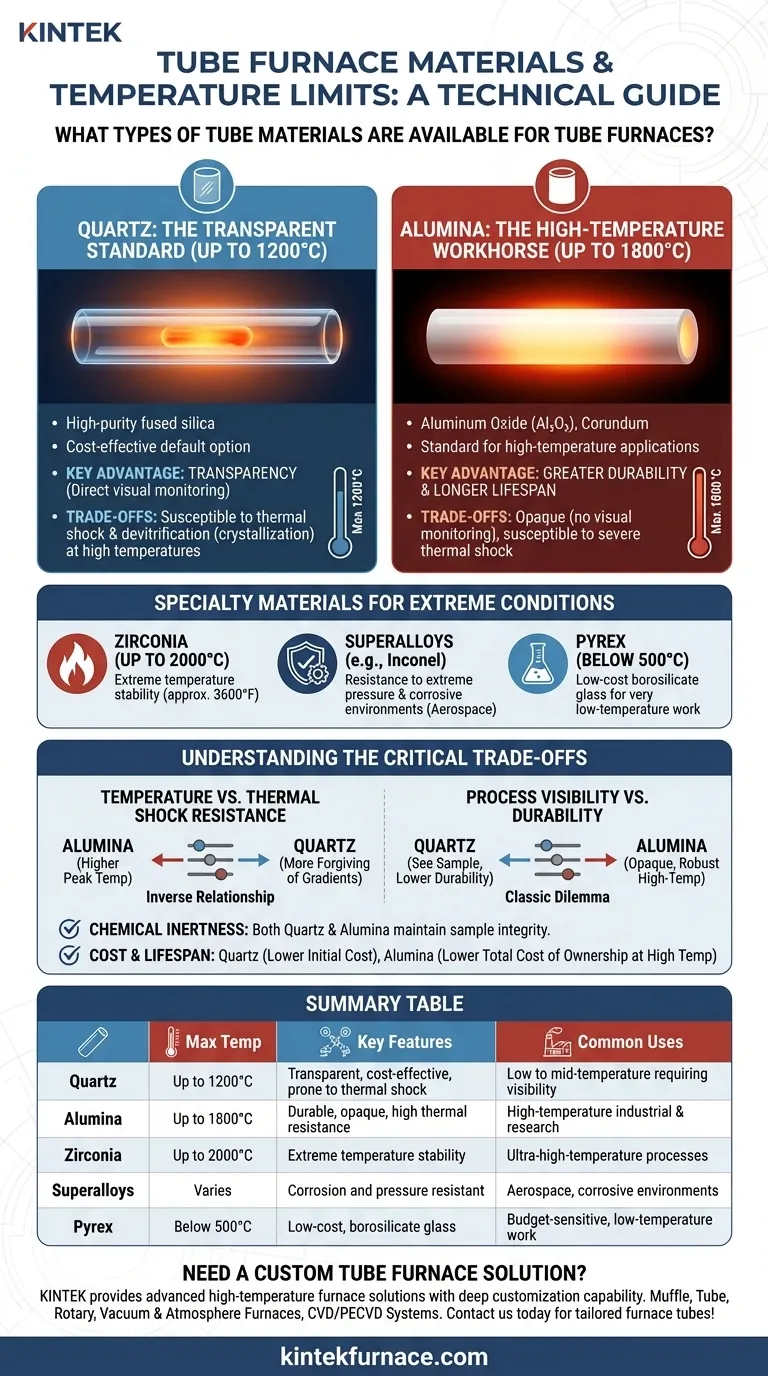

The primary materials for tube furnaces are quartz and alumina, chosen for their distinct temperature capabilities and physical properties. Quartz tubes are generally suitable for applications up to 1200°C, offering transparency at a lower cost. For higher temperatures up to 1800°C, opaque alumina tubes are the standard due to their superior durability and thermal resistance.

Choosing the right tube material is a critical decision that extends beyond just the maximum temperature. You must balance thermal performance against factors like chemical compatibility, resistance to thermal shock, and budget to ensure the integrity of your experiment and the longevity of your equipment.

A Breakdown of Common Tube Materials

The material of your process tube is the single most important factor defining the operational limits and capabilities of your furnace. Each material offers a unique profile of benefits and limitations.

Quartz: The Transparent Standard (Up to 1200°C)

Quartz is a form of high-purity fused silica, making it a popular choice for a wide range of thermal processes. It is often the default, cost-effective option for many labs.

Its key advantage is transparency, allowing for direct visual observation of the sample during processing. This is invaluable for monitoring physical changes, such as melting or color shifts.

However, quartz is susceptible to thermal shock and devitrification (crystallization) with repeated use at high temperatures, which can make it brittle and lead to failure over time.

Alumina: The High-Temperature Workhorse (Up to 1800°C)

Alumina (Aluminum Oxide, Al₂O₃), also known as corundum, is the standard for high-temperature applications that exceed the limits of quartz.

It offers significantly greater durability and a much longer operational lifespan under continuous high-temperature conditions. Its robust nature makes it ideal for demanding industrial and research processes.

The primary trade-off is that alumina is opaque, preventing any visual monitoring of the sample. It can also be more susceptible to fracture from severe thermal shock than quartz, especially in larger diameter tubes.

Specialty Materials for Extreme Conditions

For applications that push beyond the capabilities of standard materials, several specialty options exist.

Zirconia tubes are required for extreme temperatures approaching 2000°C (approximately 3600°F), offering stability where even alumina would fail.

Superalloys, such as Inconel, are custom metal tube options. They are not chosen for temperature alone, but for specific applications requiring resistance to extreme pressure or corrosive chemical environments, often found in aerospace research.

Pyrex (borosilicate glass) is a common material for very low-temperature work. While not a high-performance material, it serves as a low-cost option for processes that operate well below 500°C.

Understanding the Critical Trade-offs

Selecting a tube is not a simple matter of matching your process temperature to the material's limit. You must consider the interplay between different material properties.

Temperature vs. Thermal Shock Resistance

There is an inverse relationship here. Alumina handles higher peak temperatures but is more sensitive to rapid heating or cooling rates. Quartz has a lower temperature ceiling but is generally more forgiving of thermal gradients, though it still has limits.

Process Visibility vs. Durability

This is the classic Quartz vs. Alumina dilemma. Do you need to see your sample? If so, you are limited to quartz and its associated temperature ceiling and lower durability. If your process is well-characterized and does not require observation, alumina is the more robust, high-temperature choice.

Chemical Inertness and Contamination

Both quartz and alumina are chosen for their ability to maintain sample integrity. They are highly chemically inert under most conditions, preventing the tube itself from reacting with or contaminating the sample materials being processed.

Cost and Lifespan

Quartz has a lower initial purchase price, making it attractive for budget-conscious operations or infrequent use. However, its shorter lifespan at high temperatures can lead to higher replacement costs over time.

Alumina has a higher upfront cost but its longevity in demanding environments often results in a lower total cost of ownership for high-frequency, high-temperature work.

Selecting the Right Tube for Your Application

Your choice should be dictated by the specific goals and constraints of your thermal process.

- If your primary focus is process visualization below 1200°C: Quartz is your ideal choice due to its transparency and cost-effectiveness.

- If your primary focus is high-temperature processing up to 1800°C: Alumina provides the necessary durability and thermal performance, despite being opaque.

- If your primary focus is budget-sensitive, low-temperature work (below 500°C): A Pyrex tube can be a sufficient and economical option.

- If your primary focus is operating in extreme temperatures near 2000°C or in highly corrosive environments: You must investigate specialty materials like Zirconia or custom superalloys.

By understanding these material properties, you can select a process tube that ensures both the accuracy of your results and the reliability of your equipment.

Summary Table:

| Material | Max Temperature | Key Features | Common Uses |

|---|---|---|---|

| Quartz | Up to 1200°C | Transparent, cost-effective, prone to thermal shock | Low to mid-temperature processes requiring visibility |

| Alumina | Up to 1800°C | Durable, opaque, high thermal resistance | High-temperature industrial and research applications |

| Zirconia | Up to 2000°C | Extreme temperature stability | Ultra-high-temperature processes |

| Superalloys | Varies | Corrosion and pressure resistant | Aerospace, corrosive environments |

| Pyrex | Below 500°C | Low-cost, borosilicate glass | Budget-sensitive, low-temperature work |

Need a Custom Tube Furnace Solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your lab's performance with tailored furnace tubes!

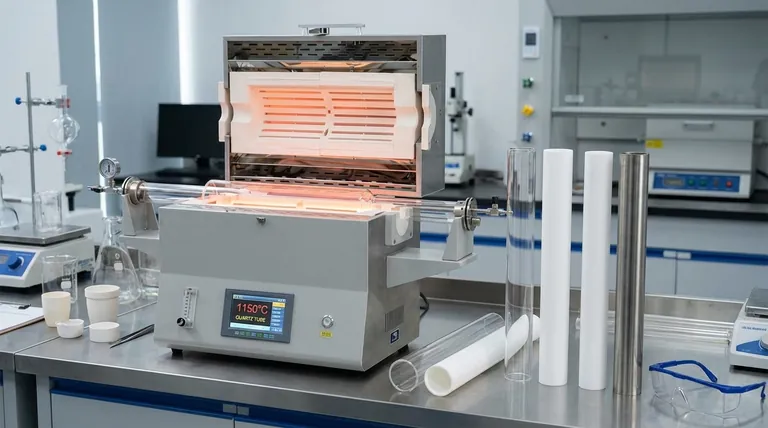

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What maintenance is required for a vacuum tube furnace? Ensure Longevity and Safety in Your Lab

- What role does a Vacuum Tube Furnace play in NPCu annealing? Achieve Precise Structural Homogenization

- Why is a tube furnace equipped with an atmosphere control system required for synthesizing h-Zn-Co-O solid solutions?

- What role does a high-temperature tube furnace play in graphite recycling? Restoring Purity and Structure

- What are the primary functions of a precision gas filtration device? Maximize Data Integrity in Drop Tube Furnaces

- What are the primary uses of tube furnaces in academic and industrial settings? Unlock Precision Thermal Processing

- What are tube furnaces made of? Choose the Right Material for Your Thermal Process

- What are some common applications of lab tubular furnaces in material science? Unlock Precision in Heat Treatment and Synthesis