The Vacuum Induction Melting (VIM) furnace serves as the critical foundational step in the manufacturing of flexible iron-based amorphous nanocrystalline materials. Its primary role is to synthesize a high-purity master alloy ingot by melting specific raw materials—iron, silicon, copper, boron, and phosphorus—under a protective argon atmosphere.

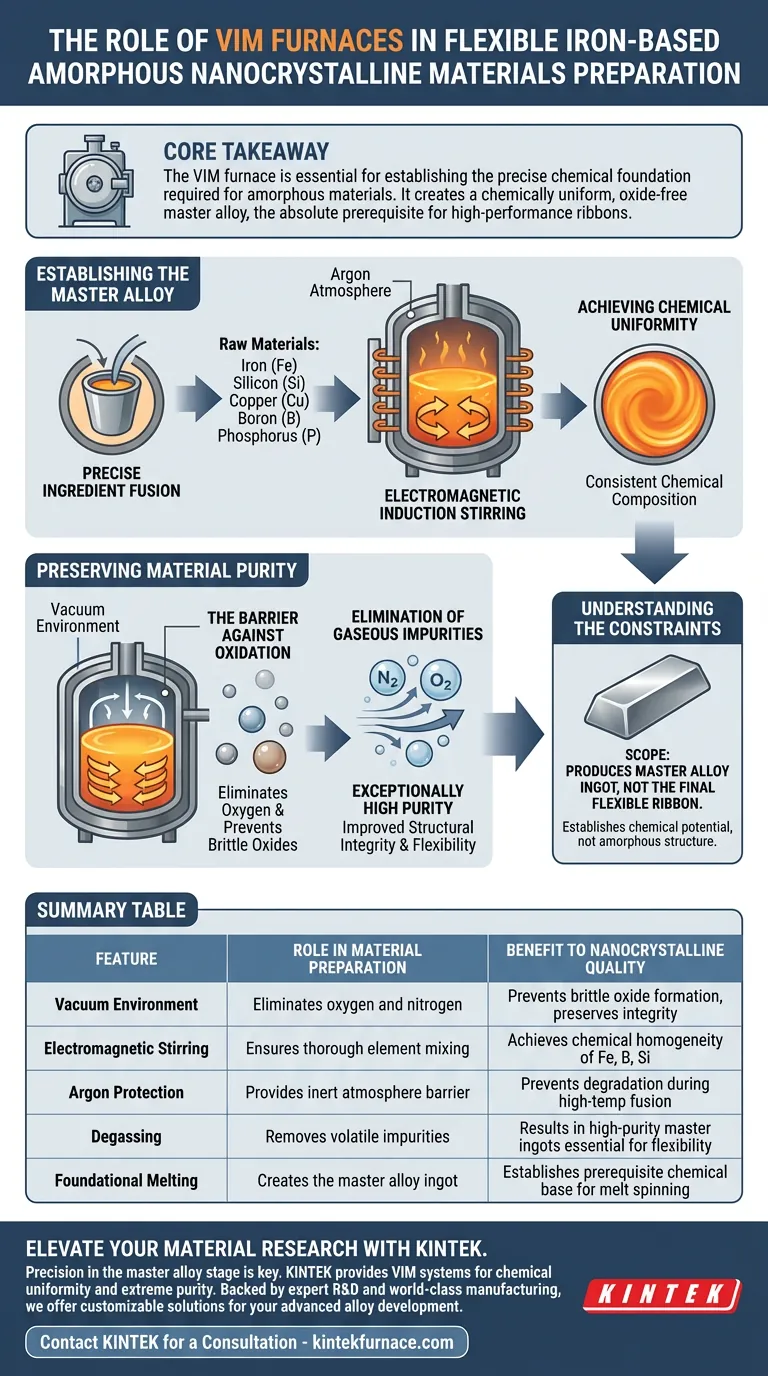

Core Takeaway The VIM furnace is essential for establishing the precise chemical foundation required for amorphous materials. By utilizing electromagnetic stirring within a vacuum, it creates a chemically uniform, oxide-free master alloy, which is the absolute prerequisite for producing high-performance amorphous ribbons.

Establishing the Master Alloy

Precise Ingredient Fusion

The process begins with the introduction of high-purity raw materials into the furnace.

For flexible iron-based nanocrystalline materials, the specific charge typically includes iron, silicon, copper, boron, and phosphorus.

The VIM furnace melts these distinct elements together under a controlled argon protective atmosphere to prevent immediate degradation.

Achieving Chemical Uniformity

Mere melting is insufficient for high-performance materials; the mixture must be perfectly homogenous.

The VIM furnace utilizes electromagnetic induction stirring during the melting phase.

This mechanism constantly agitates the molten pool, ensuring that heavy and light elements mix thoroughly to create a master alloy with a consistent chemical composition throughout.

Preserving Material Purity

The Barrier Against Oxidation

At the high temperatures required for melting, elements like iron and silicon are highly susceptible to reacting with oxygen.

The VIM furnace creates a vacuum environment that acts as an absolute barrier against oxidation.

By eliminating oxygen from the chamber, the furnace ensures the raw materials retain their intended properties without forming brittle oxides that would degrade the final product.

Elimination of Gaseous Impurities

Beyond preventing new oxidation, the process actively refines the material.

The vacuum environment facilitates the removal of volatile impurities and dissolved gases, such as nitrogen and oxygen, from the molten metal.

This results in a master ingot of exceptionally high purity, a critical factor for the structural integrity and flexibility of the final nanocrystalline material.

Understanding the Constraints

The Scope of the VIM Process

It is vital to recognize that the VIM furnace produces the master alloy ingot, not the final flexible ribbon.

While it establishes the chemical potential of the material, it does not induce the amorphous (non-crystalline) structure itself.

The amorphous state is achieved in subsequent processing steps (such as melt spinning); the VIM furnace is solely responsible for providing the defect-free, chemically correct liquid or ingot required for those steps to succeed.

Ensuring Process Success

If your primary focus is Chemical Consistency:

- Rely on the electromagnetic stirring capabilities of the VIM to prevent segregation of lighter elements like boron and silicon within the iron matrix.

If your primary focus is Material Purity:

- Ensure the vacuum and argon systems are functioning optimally to effectively strip volatile impurities and prevent oxidation during the high-temperature melt.

The quality of your final flexible amorphous material is directly dictated by the purity and uniformity of the master ingot produced in the VIM furnace.

Summary Table:

| Feature | Role in Material Preparation | Benefit to Nanocrystalline Quality |

|---|---|---|

| Vacuum Environment | Eliminates oxygen and nitrogen | Prevents brittle oxide formation and preserves material integrity |

| Electromagnetic Stirring | Ensures thorough element mixing | Achieves chemical homogeneity of iron, boron, and silicon |

| Argon Protection | Provides inert atmosphere barrier | Prevents degradation of reactive elements during high-temp fusion |

| Degassing | Removes volatile impurities | Results in high-purity master ingots essential for flexibility |

| Foundational Melting | Creates the master alloy ingot | Establishes the prerequisite chemical base for melt spinning |

Elevate Your Material Research with KINTEK

Precision in the master alloy stage is the difference between a brittle failure and a high-performance flexible ribbon. KINTEK provides industry-leading Vacuum Induction Melting (VIM) systems designed to deliver the chemical uniformity and extreme purity your nanocrystalline materials demand.

Backed by expert R&D and world-class manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are developing advanced amorphous alloys or scaling laboratory production, our high-temperature solutions are tailored to your unique specifications.

Ready to optimize your alloy synthesis? Contact KINTEK today for a consultation!

Visual Guide

References

- Ravi Gautam, H. Sepehri‐Amin. Creation of flexible spin-caloritronic material with giant transverse thermoelectric conversion by nanostructure engineering. DOI: 10.1038/s41467-024-46475-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do induction furnaces contribute to sustainability in metal casting? Boost Efficiency and Cut Waste

- What technical advantages do medium-frequency induction furnaces provide? Enhance Your Ductile Iron Production

- What does the driver circuit in an IGBT-based induction heater consist of and what is its function? Master High-Frequency Power Control

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is the best material for induction heating? Choose the Right Metal for Maximum Efficiency

- What is the primary purpose of using induction furnaces under vacuum or protective atmospheres? Achieve Purity and Performance in High-Performance Alloys

- What factors influence induction heater circuit design? Optimize Power, Frequency, and Material for Efficiency

- What is vacuum arc melting (VAR) and what is its primary purpose? Achieve Superior Metal Purity and Performance