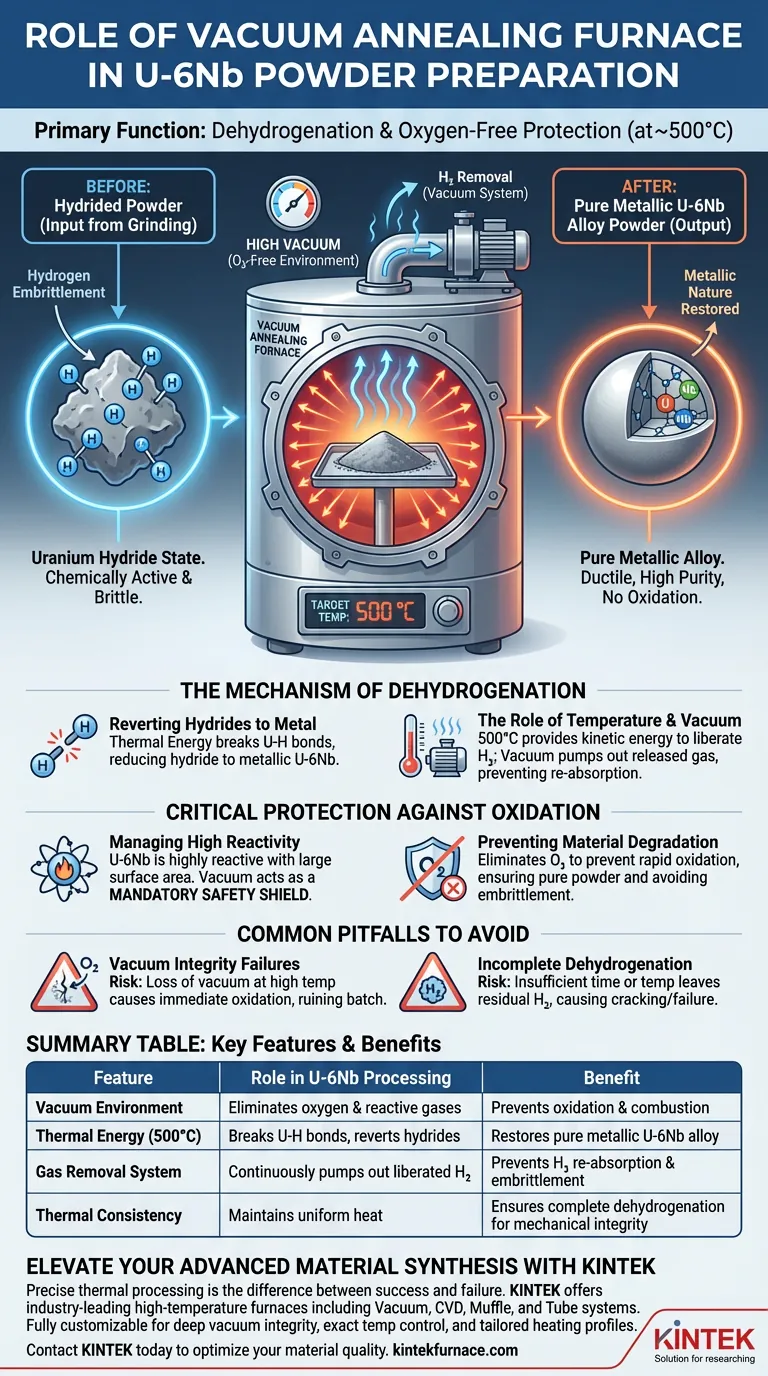

The primary role of a vacuum annealing furnace in Uranium-Niobium (U-6Nb) powder preparation is to perform dehydrogenation, converting the material from a hydride state back into a pure metallic alloy. Operating typically at 500 °C, the furnace drives off hydrogen while strictly maintaining an oxygen-free environment to prevent the combustion or degradation of the highly reactive powder.

The furnace acts as a chemical restoration stage, using thermal energy to release hydrogen introduced during grinding. It restores the metallic nature of the U-6Nb alloy without allowing the oxidation that would inevitably occur in a non-vacuum environment.

The Mechanism of Dehydrogenation

Reverting Hydrides to Metal

The powder entering the furnace is essentially a uranium hydride, often a result of the grinding process where hydrogen is used to embrittle the metal for easier comminution.

The vacuum annealing furnace reverses this process. By applying heat under vacuum, it breaks the chemical bond between the metal and the hydrogen, effectively reducing the hydride back into metallic Uranium-Niobium (U-6Nb) powder.

The Role of Temperature

This chemical reversion is driven by specific thermal conditions, typically around 500 °C.

At this temperature, the kinetic energy is sufficient to liberate the hydrogen atoms from the metal lattice. The vacuum system then continuously pumps this released hydrogen gas out of the chamber to prevent re-absorption.

Critical Protection Against Oxidation

Managing High Reactivity

U-6Nb powder is chemically "active," meaning it reacts aggressively with oxygen.

This reactivity is amplified because the powder has a large specific surface area compared to solid metal. The vacuum environment is not just a facilitator for hydrogen removal; it is a mandatory safety shield.

Preventing Material degradation

If this heating process occurred in air, the powder would oxidize rapidly, ruining the alloy.

By eliminating oxygen from the chamber, the furnace ensures the resulting powder remains pure. This prevents the formation of oxide layers that would lead to material embrittlement and poor performance in final applications.

Common Pitfalls to Avoid

Vacuum Integrity Failures

The most significant risk in this process is a loss of vacuum pressure at high temperatures.

Because the powder is heated to 500 °C, even a microscopic leak or insufficient vacuum level will cause immediate oxidation. This can render the entire batch usable and potentially hazardous.

Incomplete Dehydrogenation

There is a trade-off between cycle time and material purity.

If the furnace cycle is too short or the temperature fluctuates below the target, residual hydrogen may remain in the core of the particles. This residual hydrogen can cause cracking or failure in the final consolidated part.

Ensuring Quality in U-6Nb Preparation

To maximize the effectiveness of your annealing process, align your operational parameters with your specific quality targets:

- If your primary focus is Chemical Purity: Ensure your vacuum system is capable of maintaining deep vacuum levels to eliminate even trace amounts of oxygen during the heating ramp.

- If your primary focus is Mechanical Integrity: Verify that the hold time at 500 °C is sufficient to achieve complete dehydrogenation throughout the entire powder batch.

Successful U-6Nb preparation relies on the vacuum annealing furnace to simultaneously act as a chemical reactor for hydrogen removal and a protective vessel against oxidation.

Summary Table:

| Feature | Role in U-6Nb Processing | Benefit |

|---|---|---|

| Vacuum Environment | Eliminates oxygen and reactive gases | Prevents oxidation and combustion of reactive powder |

| Thermal Energy (500°C) | Breaks chemical bonds in uranium hydrides | Reverts hydrides back to pure metallic U-6Nb alloy |

| Gas Removal System | Continuously pumps out liberated hydrogen | Prevents hydrogen re-absorption and material embrittlement |

| Thermal Consistency | Maintains uniform heat across high surface area | Ensures complete dehydrogenation for mechanical integrity |

Elevate Your Advanced Material Synthesis with KINTEK

Precise thermal processing is the difference between high-performance alloys and material failure. KINTEK provides industry-leading laboratory high-temperature furnaces—including Vacuum, CVD, Muffle, and Tube systems—engineered to meet the rigorous demands of reactive metal processing like U-6Nb.

Backed by expert R&D and precision manufacturing, our systems are fully customizable to ensure your laboratory achieves:

- Deep vacuum integrity to eliminate oxidation risks.

- Exact temperature control for complete chemical restoration.

- Tailored heating profiles for unique alloy requirements.

Contact KINTEK today to discuss your specific research or production needs and discover how our specialized furnace technology can optimize your material quality.

Visual Guide

References

- Investigation of In Situ and Ex Situ Passivation of Pyrophoric Uranium–Niobium Alloy Powder. DOI: 10.3390/app15126431

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does vacuum tempering contribute to energy efficiency? Superior furnace design slashes thermal waste and cuts costs.

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What are the main advantages of vacuum heat treatment? Achieve Superior Metallurgical Outcomes and Cost Efficiency

- What are the key features that make horizontal hinged vacuum furnaces popular? Unlock Precision and Accessibility for Your Lab

- Why use a vacuum drying oven for mesoporous silica? Protect High Surface Area and Structural Integrity

- How does vacuum heat treatment work? Achieve Cleaner, Stronger Materials with Precision

- What role does a high-temperature vacuum furnace play in the desilication of biomass? Achieve Ultra-High Purity Carbon

- What challenges does vacuum brazing pose for the vacuum system? Master Gas Load Management for Flawless Joints