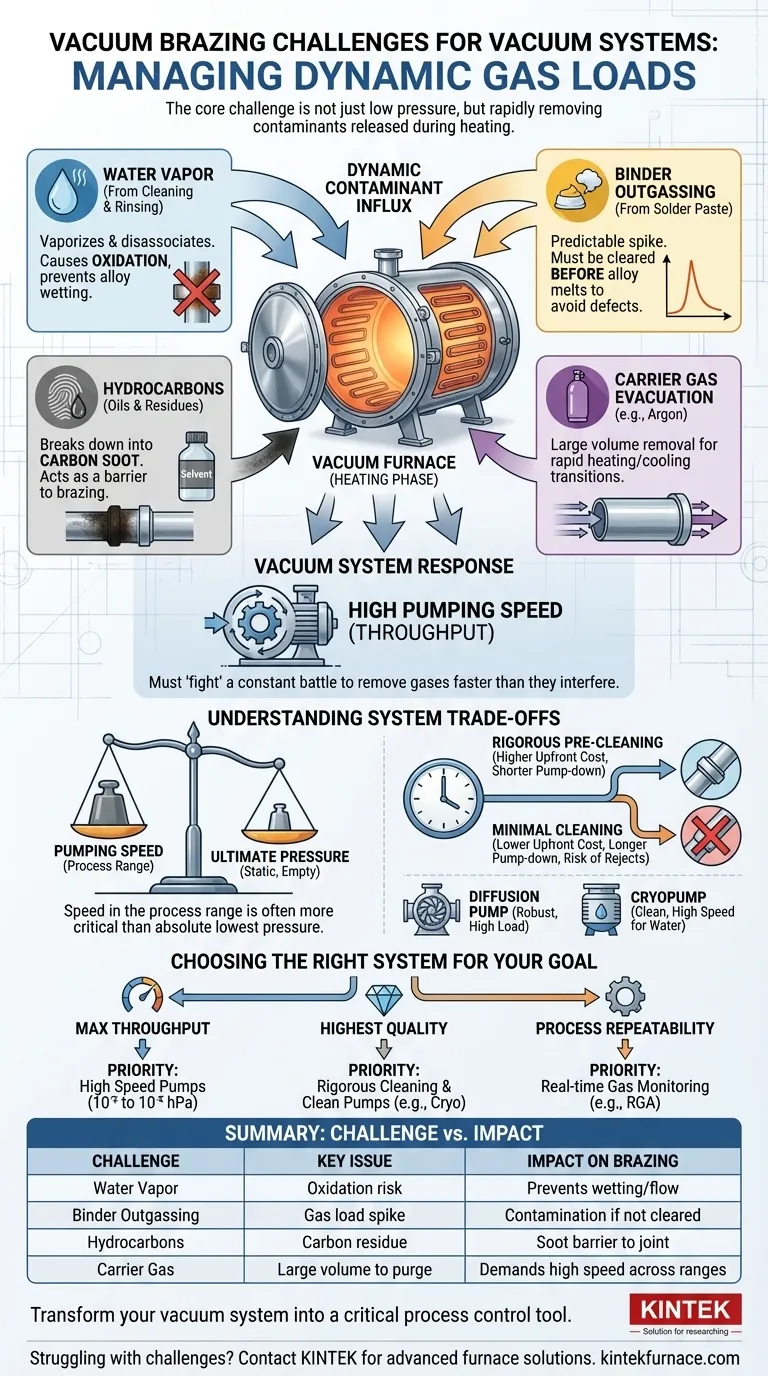

For a vacuum system, the primary challenges of vacuum brazing are not just reaching a low pressure, but actively managing the significant gas loads released during the heating process. These challenges include handling outgassing from solder binders, removing residual water vapor from cleaning, evacuating hydrocarbons, and purging carrier gases, all of which demand a system with very high pumping speed in the high-vacuum range.

The core challenge in vacuum brazing is dynamic gas load management. A successful system is not defined by the ultimate pressure it can reach in an empty, cold state, but by its ability to rapidly remove contaminants released by the workpiece during the thermal cycle.

The Core Challenge: A Dynamic vs. Static Vacuum

A common misconception is that vacuum brazing simply requires a furnace that can reach a deep vacuum. The reality is far more demanding.

The process itself, particularly the heating phase, actively introduces contaminants into the vacuum environment. The vacuum system must therefore fight a constant battle to remove these gases faster than they can interfere with the braze joint.

Water Vapor: The Invisible Enemy

Parts entering the furnace are often cleaned and rinsed with water. Even microscopic amounts of trapped water vapor can be a major source of contamination.

When heated, this water vaporizes, increasing the chamber pressure. More importantly, it can disassociate into oxygen and hydrogen, which will readily oxidize the metal surfaces, preventing the braze alloy from wetting and flowing properly.

Binder Outgassing: The Predictable Gas Load

Many braze filler metals are supplied as a paste, which includes an organic binder to hold the metal powder in place.

These binders are designed to burn off completely during the initial heating phase of the braze cycle. This creates a large, but predictable, spike in gas load that the vacuum system must handle efficiently to clear the contaminants before the braze alloy melts.

Hydrocarbons: The Residue of Preparation

Oils from machining, fingerprints, or cleaning solvents can leave a thin film of hydrocarbons on the part surfaces.

Like binders, these vaporize upon heating. If not pumped away quickly, they can break down at high temperatures and deposit a layer of carbon, or "soot," on the joint surfaces, which acts as a barrier to brazing.

Carrier Gas Evacuation: The Need for Versatility

In some processes, an inert carrier gas like argon is used for rapid convection heating or for rapid cooling at the end of the cycle.

The vacuum system must be capable of evacuating this large volume of gas quickly to transition between atmospheric pressure and the high-vacuum phase of the process. This requires high throughput across a very wide pressure range.

Understanding the System Trade-offs

Specifying a vacuum system for brazing involves balancing competing priorities. Understanding these trade-offs is key to building a reliable process.

Pumping Speed vs. Ultimate Pressure

It is critical to distinguish between a pump's ultimate pressure and its pumping speed (or throughput). A pump may be able to reach a very deep vacuum (e.g., 10⁻⁸ hPa) in a clean, empty chamber, but lack the speed to handle a large gas load at the actual process pressure (e.g., 10⁻⁵ hPa).

For brazing, high pumping speed in the process pressure range is almost always more important than the absolute lowest pressure the system can achieve.

The True Cost of Cleanliness

Investing in rigorous pre-cleaning procedures and clean assembly rooms adds upfront cost and time.

However, this investment significantly reduces the contamination load inside the furnace. This allows for shorter pump-down times, less stress on the vacuum system, and a more repeatable, higher-quality brazing process with fewer rejected parts.

Choosing the Right Pump Type

Different vacuum pumps handle different gases with varying efficiency. Diffusion pumps are robust and handle high gas loads well, but risk oil backstreaming if not properly trapped.

Cryopumps offer extremely high pumping speeds for water vapor and are inherently clean, but have a finite capacity for gases and require periodic regeneration. The choice depends on the specific contaminants expected and the level of cleanliness required.

Making the Right Choice for Your Goal

Your ideal vacuum system configuration depends directly on your primary operational goal.

- If your primary focus is maximum throughput and short cycle times: Prioritize a pumping system with the highest possible speed in the 10⁻³ to 10⁻⁵ hPa range to overcome outgassing spikes quickly.

- If your primary focus is the absolute highest joint quality and purity: Emphasize rigorous pre-cleaning protocols and select an inherently clean high-vacuum pump, like a cryopump, to eliminate any risk of hydrocarbon contamination.

- If your primary focus is process repeatability and reliability: Invest in instrumentation to monitor the gas load in real-time (e.g., a Residual Gas Analyzer) to ensure each cycle behaves identically.

By understanding these gas dynamics, you transform the vacuum system from a simple utility into your most critical tool for process control.

Summary Table:

| Challenge | Key Issues | Impact on Brazing |

|---|---|---|

| Water Vapor | Release from cleaning, oxidation risk | Prevents wetting and flow of braze alloy |

| Binder Outgassing | Gas load from paste binders during heating | Requires rapid removal to avoid contamination |

| Hydrocarbons | Residues from oils or solvents | Can deposit carbon, blocking joint formation |

| Carrier Gas Evacuation | Need to purge inert gases quickly | Demands high pumping speed across pressure ranges |

Struggling with vacuum brazing challenges? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to precisely manage gas loads and enhance your brazing process for higher throughput, superior joint quality, and repeatability. Contact us today to discuss how our tailored systems can solve your specific vacuum brazing needs and boost your lab's performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment