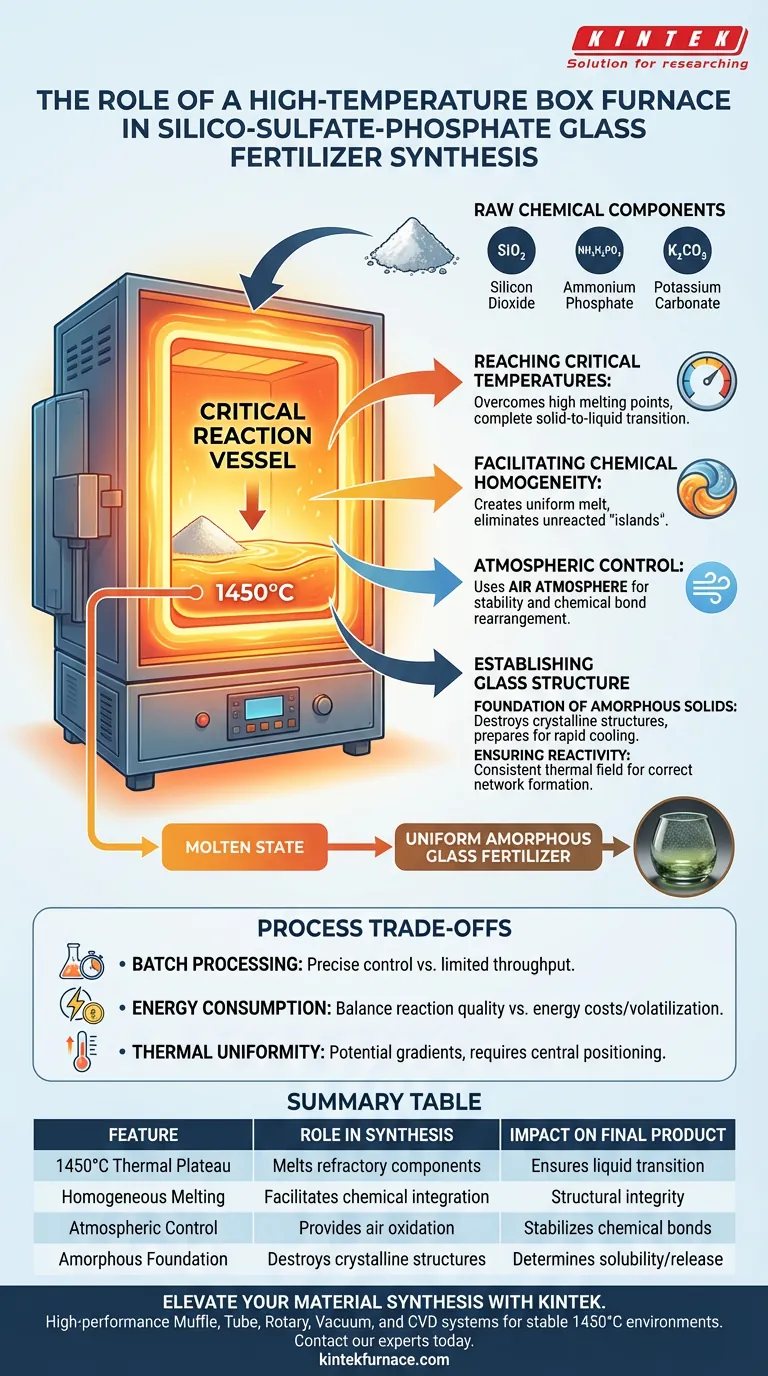

A high-temperature box furnace serves as the critical reaction vessel where raw chemical components are transformed into a unified glass matrix. Specifically, it generates the extreme thermal environment—up to 1450°C—required to melt silicon dioxide, ammonium phosphate, and potassium carbonate into a homogeneous liquid phase.

Core Takeaway The furnace is not merely a heating device; it is the driver of chemical synthesis that converts a physical mixture of distinct oxides into a single, uniform melt. This transformation is the absolute prerequisite for creating the amorphous structure that defines a functional glass fertilizer.

The Mechanism of Synthesis

Reaching Critical Temperatures

To synthesize silico-sulfate-phosphate glass, the furnace must maintain a consistent temperature of 1450°C.

At this specific thermal plateau, the furnace overcomes the high melting points of refractory components like silicon dioxide. This ensures the raw materials transition completely from solid powder to a liquid state.

Facilitating Chemical Homogeneity

The box furnace creates a static, controlled environment where the molten components can integrate.

By maintaining high heat, the furnace ensures that various oxide components react completely with one another. This eliminates "islands" of unreacted material, resulting in a uniform melt throughout the crucible.

Atmospheric Control

The synthesis of this specific glass fertilizer requires an air atmosphere.

The design of the box furnace allows for this oxidation environment, which is necessary for the stability of the melt as the chemical bonds rearrange.

Establishing the Glass Structure

The Foundation of Amorphous Solids

The primary goal of this heating process is to destroy the crystalline structure of the raw materials.

By achieving a fully liquid state, the furnace prepares the material for rapid cooling later. The melt created in the furnace serves as the foundation for the subsequent amorphous glass structure, which determines the fertilizer's solubility and release properties.

Ensuring Reactivity

The quality of the thermal processing in the furnace directly impacts the chemical potential of the final product.

A consistent thermal field ensures that the glass network forms correctly. Without this precise melting phase, the resulting material would lack the structural integrity required to function effectively as a fertilizer.

Understanding the Process Trade-offs

Batch Processing Limitations

High-temperature box furnaces typically operate as batch processing units rather than continuous flow systems.

While this allows for precise control over individual experimental batches, it limits throughput compared to continuous tank furnaces used in industrial mass production. It is ideal for synthesis and laboratory optimization but requires scaling strategies for commercial volume.

Energy Consumption

Maintaining a chamber at 1450°C requires significant energy input.

The operator must balance the need for a complete reaction against energy costs. Insufficient time at temperature leads to incomplete melting, while excessive time wastes energy and risks volatilizing certain components.

Thermal Uniformity Challenges

While box furnaces provide a general thermal field, gradients can exist near the door or heating elements.

If the raw material mixture is not positioned centrally, or if the furnace volume is overloaded, the melt may suffer from uneven heating. This results in a product with inconsistent physical properties.

Making the Right Choice for Your Goal

To maximize the effectiveness of your synthesis process, align your furnace usage with your specific objectives:

- If your primary focus is research and formulation: Prioritize temperature stability and atmospheric control to ensure that every variable in your 1450°C melt is isolated and reproducible.

- If your primary focus is material quality: Ensure your dwell time is sufficient to achieve a completely uniform melt, preventing unreacted silica inclusions that weaken the glass structure.

The box furnace is the gatekeeper of quality; precise thermal management here dictates the ultimate performance of the fertilizer.

Summary Table:

| Feature | Role in Glass Fertilizer Synthesis | Impact on Final Product |

|---|---|---|

| 1450°C Thermal Plateau | Melts refractory components like silicon dioxide | Ensures transition from solid powder to liquid state |

| Homogeneous Melting | Facilitates chemical integration of oxides | Eliminates unreacted material for structural integrity |

| Atmospheric Control | Provides necessary air oxidation environment | Stabilizes chemical bonds during rearrangement |

| Amorphous Foundation | Destroys crystalline structures of raw materials | Determines fertilizer solubility and release properties |

Elevate Your Material Synthesis with KINTEK

Precision is the difference between a physical mixture and a high-performance glass fertilizer. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered to maintain the stable 1450°C environments required for your most demanding chemical syntheses. Whether you are optimizing a lab-scale formulation or scaling for production, our customizable lab high-temperature furnaces provide the thermal uniformity and atmospheric control you need.

Ready to achieve a perfect melt? Contact our experts today to find the ideal furnace solution for your unique research goals.

Visual Guide

References

- Anna Berezicka, Magdalena Szumera. Alteration of Sulfur-Bearing Silicate-Phosphate (Agri)Glasses in Soil Environment: Structural Characterization and Chemical Reactivity of Fertilizer Glasses: Insights from ‘In Vitro’ Studies. DOI: 10.3390/molecules30081684

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How are muffle furnaces classified according to control devices? Choose the Right Control for Precision Heating

- Why is a precision muffle furnace required for TiO2 sintering? Optimize Your Dye-Sensitized Solar Cell Performance

- Why is isolation from contaminants important in a digital muffle furnace? Ensure Purity and Accuracy in High-Temp Processes

- How does an industrial box resistance furnace ensure sufficient bainite transformation? Expert Lab Simulation Tips

- What principles do muffle furnaces operate on? Master Heat, Isolation, and Uniform Transfer

- What role does a muffle furnace play in LDH-derived catalysts? Unlock High-Performance Catalyst Synthesis

- What safety measures should be observed regarding the surroundings of a muffle furnace? Ensure a Secure Lab Setup

- What are some common uses of muffle furnaces in material testing? Unlock Precise Heat Treatment for Accurate Results