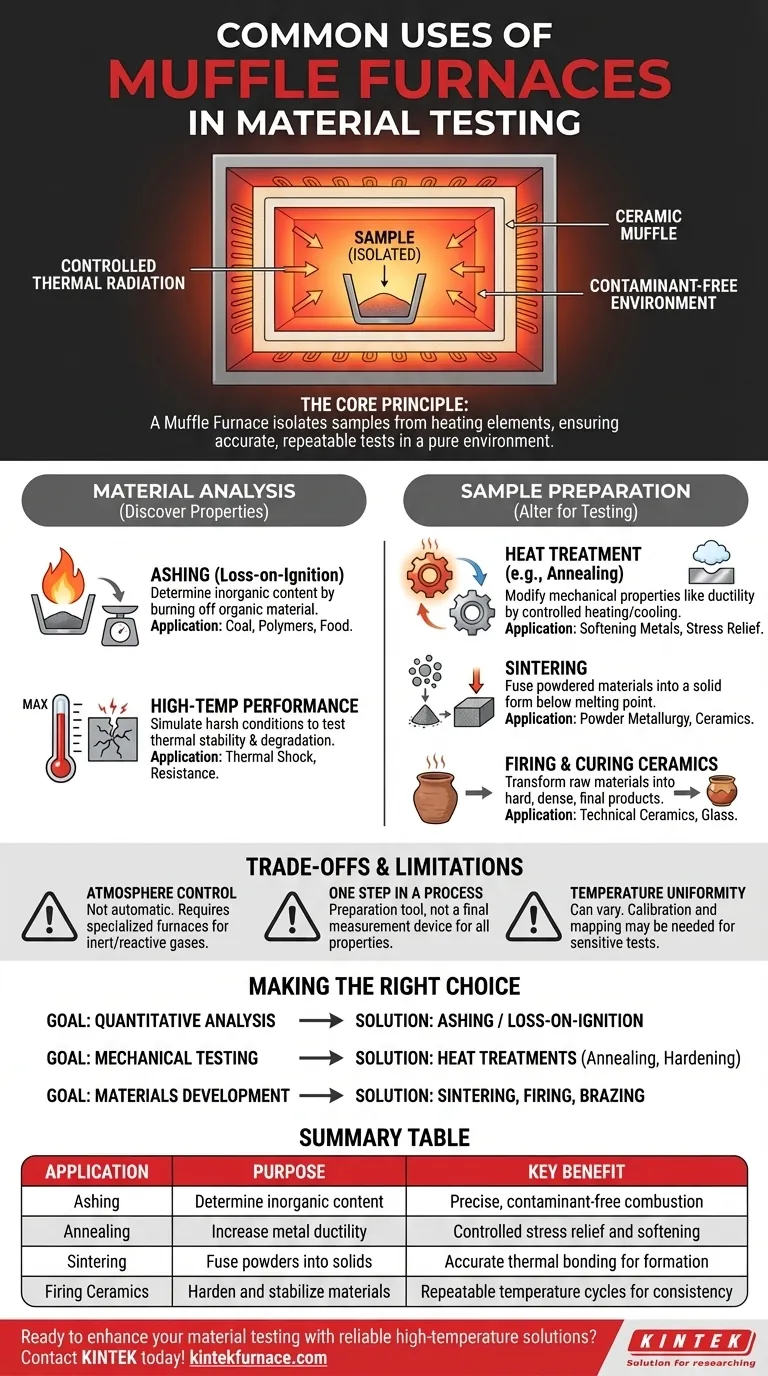

In material testing, a muffle furnace is an essential tool for two primary functions: altering a material's physical properties through precise heat treatment and analyzing its composition. Common applications include determining the inorganic (ash) content of a sample, annealing metals to increase their ductility, and sintering powdered materials into a solid form for further evaluation.

A muffle furnace's true value lies not just in its ability to generate high temperatures, but in its "muffle"—an insulating chamber that isolates the sample from heating elements. This guarantees a contaminant-free environment, which is the foundation for accurate and repeatable material testing.

The Core Principle: A Controlled Thermal Environment

A muffle furnace is fundamentally a high-temperature oven with a critical design feature: the internal chamber, or muffle, is sealed off from the source of heat.

Why the Muffle is Crucial

In traditional furnaces, combustion byproducts or degraded heating elements can directly contact and contaminate the material being tested.

The muffle creates a barrier. It ensures that the sample is heated only by thermal radiation, providing a pure environment where results are solely dependent on temperature and atmosphere, not external contaminants.

Precision and Repeatability

This controlled environment is the key to repeatable experiments. By eliminating variables like fuel impurities, a muffle furnace allows researchers and technicians to reliably test how a material responds to specific thermal cycles.

Key Applications in Material Analysis

These applications focus on discovering a material's intrinsic properties or composition.

Determining Composition via Ashing

Ashing, or loss-on-ignition, is a quantitative technique to determine the amount of non-combustible material in a sample.

The furnace burns off all organic components at a controlled high temperature, leaving behind only the inorganic residue, or ash. Weighing the sample before and after this process precisely measures its inorganic content. This is common for testing materials like coal, polymers, and food.

Evaluating High-Temperature Performance

Muffle furnaces are used to subject materials to prolonged periods of extreme heat. This simulates harsh operating conditions and helps determine a material's thermal stability, degradation point, and resistance to thermal shock.

Key Applications in Sample Preparation

Often, the furnace is the first step in a multi-stage testing process. It prepares the material by altering its properties in a predictable way.

Modifying Mechanical Properties via Heat Treatment

Heat treatment is a broad category of processes designed to change a material's microstructure and, therefore, its physical properties.

A common example is annealing, where a metal is heated to a specific temperature and then slowly cooled. This process relieves internal stresses, softens the metal, and increases its ductility, making it less brittle.

The furnace creates the annealed sample, which is then taken to another instrument, like a tensile tester, to measure its improved strength or ductility. Other treatments include hardening, tempering, and stress relief.

Creating Solid Forms via Sintering

Sintering is the process of fusing powdered materials into a solid or porous mass using heat below the material's melting point.

This is fundamental in powder metallurgy and technical ceramics. A muffle furnace provides the precise thermal profile needed to bond the particles together, creating a testable solid component from a powder.

Firing and Curing Ceramics

For technical ceramics and glass, the firing process is what transforms the shaped raw material into a hard, dense, and stable final product. A muffle furnace provides the exact, repeatable temperature ramps and soaks required for this transformation.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is not a universal solution. Understanding its limitations is critical for accurate testing.

Atmosphere Control is Not Automatic

A standard muffle furnace operates in an ambient air atmosphere. If your process requires an inert (like argon) or reactive atmosphere, you need a specialized, often more expensive, furnace with ports for gas exchange.

It's Often One Step in a Larger Process

A muffle furnace rarely provides the final answer. It does not directly measure tensile strength, hardness, or conductivity. It is a tool used to prepare a sample for those specific tests. Misunderstanding this can lead to flawed experimental design.

Temperature Uniformity Can Vary

While high-quality furnaces offer excellent temperature uniformity, cheaper or older models can have hot and cold spots within the chamber. For sensitive processes, mapping the chamber's temperature profile is a necessary calibration step.

Making the Right Choice for Your Goal

To apply these principles effectively, align the furnace's function with your primary testing objective.

- If your primary focus is quantitative chemical analysis: Use the furnace for ashing or loss-on-ignition tests to determine a sample's inorganic content with high accuracy.

- If your primary focus is mechanical property testing: Use the furnace to perform precise heat treatments like annealing or hardening before conducting tests for tensile strength, hardness, or ductility.

- If your primary focus is materials development (e.g., ceramics or metallurgy): Use the furnace for sintering, firing, or brazing to create and evaluate new material compositions and forms.

Ultimately, mastering the muffle furnace is about leveraging its power to create a controlled thermal environment, the cornerstone of reliable materials science.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Ashing | Determine inorganic content | Precise, contaminant-free combustion |

| Annealing | Increase metal ductility | Controlled stress relief and softening |

| Sintering | Fuse powders into solids | Accurate thermal bonding for material formation |

| Firing Ceramics | Harden and stabilize materials | Repeatable temperature cycles for consistency |

Ready to enhance your material testing with reliable high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our furnaces can deliver contaminant-free, repeatable results for your specific applications!

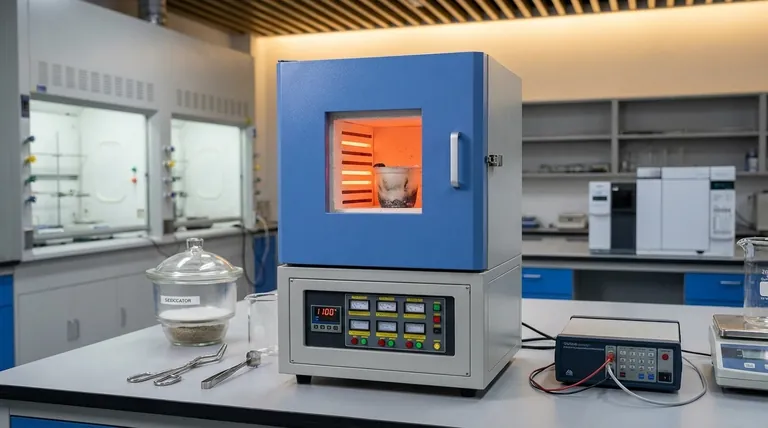

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity