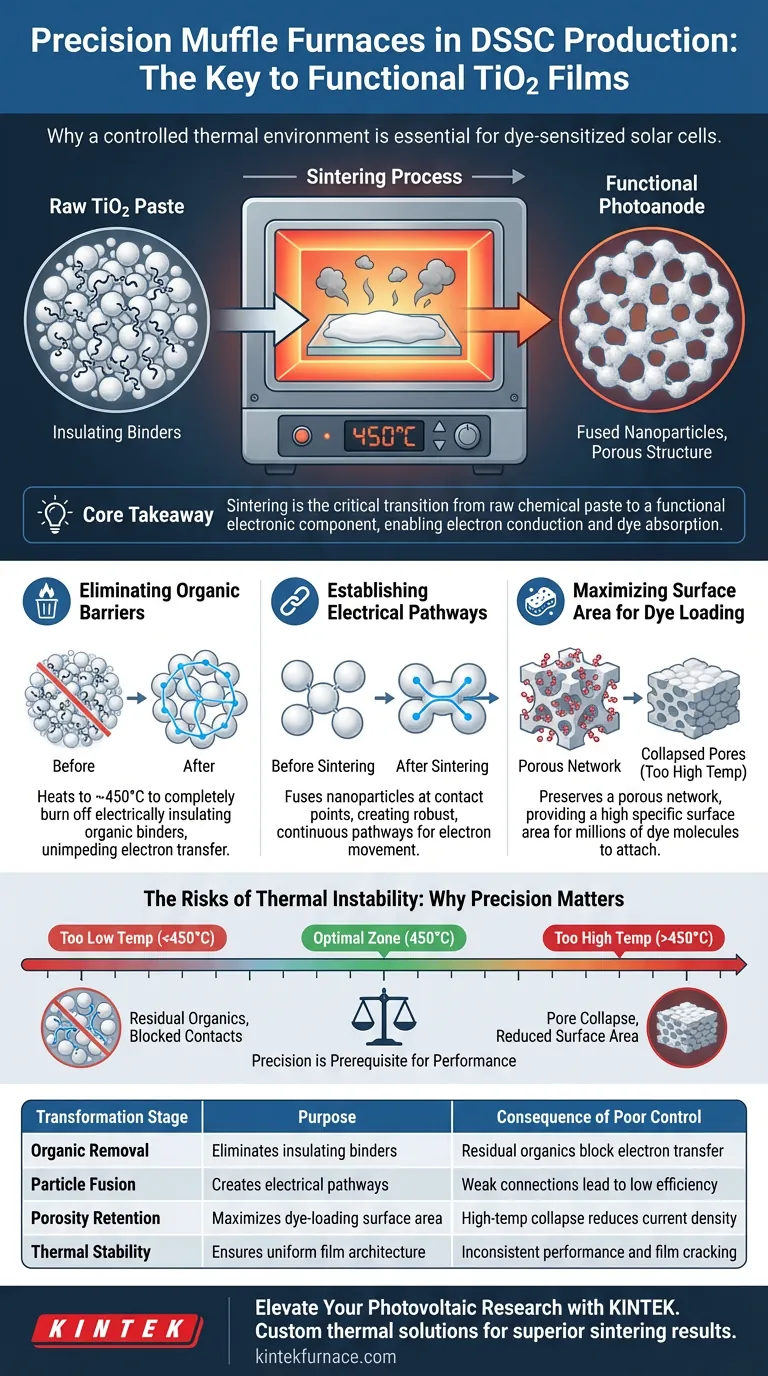

A precision muffle furnace is essential for dye-sensitized solar cell production because it provides the strictly controlled thermal environment required to transform raw TiO2 paste into a functional high-performance photoanode. By sintering the material at approximately 450 degrees Celsius, the furnace ensures the complete removal of organic additives while simultaneously fusing nanoparticles to create a mechanically stable, electrically conductive film.

Core Takeaway The sintering process acts as the critical transition from a raw chemical paste to a functional electronic component. It eliminates insulating organic binders and establishes a robust, porous network of connected nanoparticles, which is directly responsible for the solar cell's ability to absorb dye and conduct electrons.

The Critical Transformations During Sintering

To understand the necessity of this equipment, one must look beyond the simple application of heat. The furnace facilitates three distinct physical and chemical changes that define the quality of the final solar cell.

Eliminating Organic Barriers

Raw TiO2 paste is formulated with organic binders to give it the right consistency for printing or coating. However, these organic compounds are electrically insulating.

The precision furnace heats the film to roughly 450°C to burn these binders off completely. Removing these organics is non-negotiable; if they remain, they impede electron transfer and drastically lower the cell's efficiency.

Establishing Electrical Pathways

Before sintering, the TiO2 nanoparticles are merely sitting next to each other. For the cell to work, electrons must be able to travel through the film.

High-temperature treatment causes the particles to fuse slightly at their contact points. This formation of "robust electrical contacts" creates a continuous pathway for electrons to move from the dye molecules to the conductive glass substrate.

Maximizing Surface Area for Dye Loading

The power of a dye-sensitized solar cell comes from the dye molecules adsorbed onto the TiO2. To maximize power, you need to maximize the number of dye molecules.

The furnace preserves a porous network structure within the film. This porosity ensures a high specific surface area, providing millions of anchoring points for dye molecules to attach, which directly increases the cell's light-harvesting capability.

Understanding the Trade-offs: Why Precision Matters

Using a standard oven often results in failure; the specific requirement for a precision muffle furnace stems from the delicate balance required during heating.

The Risks of Thermal Instability

If the temperature fluctuates or the heating profile is inconsistent, the film's architecture will fail.

If the temperature is too low: The organic binders will not fully decompose, leaving behind residues that block electrical contact and reduce adhesion.

If the temperature is too high: The porous structure may collapse as particles fuse too aggressively (densification). This destroys the surface area needed for the dye, resulting in a solar cell that generates very little current.

Making the Right Choice for Your Process

The sintering phase is the defining moment for the photoanode's quality. Your heating strategy should be dictated by your specific performance metrics.

- If your primary focus is electrical efficiency: Ensure your furnace profile reaches the target temperature uniformly to create strong inter-particle connections without residual organics.

- If your primary focus is current density (Jsc): Prioritize precise temperature ceilings to prevent pore collapse, ensuring maximum surface area for dye adsorption.

Precision in thermal treatment is not a luxury; it is the prerequisite for a working photovoltaic device.

Summary Table:

| Transformation Stage | Purpose | Consequence of Poor Control |

|---|---|---|

| Organic Removal | Eliminates insulating binders | Residual organics block electron transfer |

| Particle Fusion | Creates electrical pathways | Weak connections lead to low efficiency |

| Porosity Retention | Maximizes dye-loading surface area | High-temp collapse reduces current density |

| Thermal Stability | Ensures uniform film architecture | Inconsistent performance and film cracking |

Elevate Your Photovoltaic Research with KINTEK

Precision in thermal treatment is the foundation of high-performance solar technology. At KINTEK, we understand that even a minor temperature fluctuation can compromise your TiO2 film's conductivity and porosity.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet the rigorous demands of dye-sensitized solar cell production. Whether you are optimizing electrical contacts or maximizing surface area, our lab high-temp furnaces provide the uniform heating and precise control your innovation requires.

Ready to achieve superior sintering results? Contact our experts today to find the perfect thermal solution for your unique laboratory needs.

Visual Guide

References

- Heather Flint, María Quintana. Betanin dye extracted from ayrampo ( <i>Opuntia soehrensii</i> ) seeds to develop dye-sensitized solar cells. DOI: 10.1039/d3ra08010b

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What specific functions must an industrial electric furnace perform for concrete fire testing? Master Thermal Cycles

- What are the standard features included with Box Furnaces? A Guide to Core Capabilities & Performance

- Why is a box-type resistance furnace utilized for long-duration heat preservation of chromium steel? Key Benefits

- What function does a high-temperature muffle furnace serve in ceramic membrane substrate preparation?

- How does a high-temperature chamber sintering furnace contribute to fluorite tailing-based geopolymer precursors?

- What are the key features of box furnaces? Versatile Thermal Solutions for Labs and Industry

- How does a programmable muffle furnace improve thin film crystal structure? Optimize Annealing for Precision Results

- How does a high-temperature box resistance furnace facilitate the heat treatment of FeAl alloys? Expert Solutions