At their core, standard Box Furnaces are robust, high-temperature systems designed for reliability and operational safety. They are typically rated to 2000°F and built with heavy plate steel construction, featuring energy-efficient ceramic fiber insulation, microprocessor-based temperature controls, and essential safety mechanisms like an emergency stop and burner management systems.

A standard Box Furnace is not just a hot box; it is an integrated system where the structural build, heating method, and control package work together to provide a durable and repeatable thermal processing environment for a wide range of industrial applications.

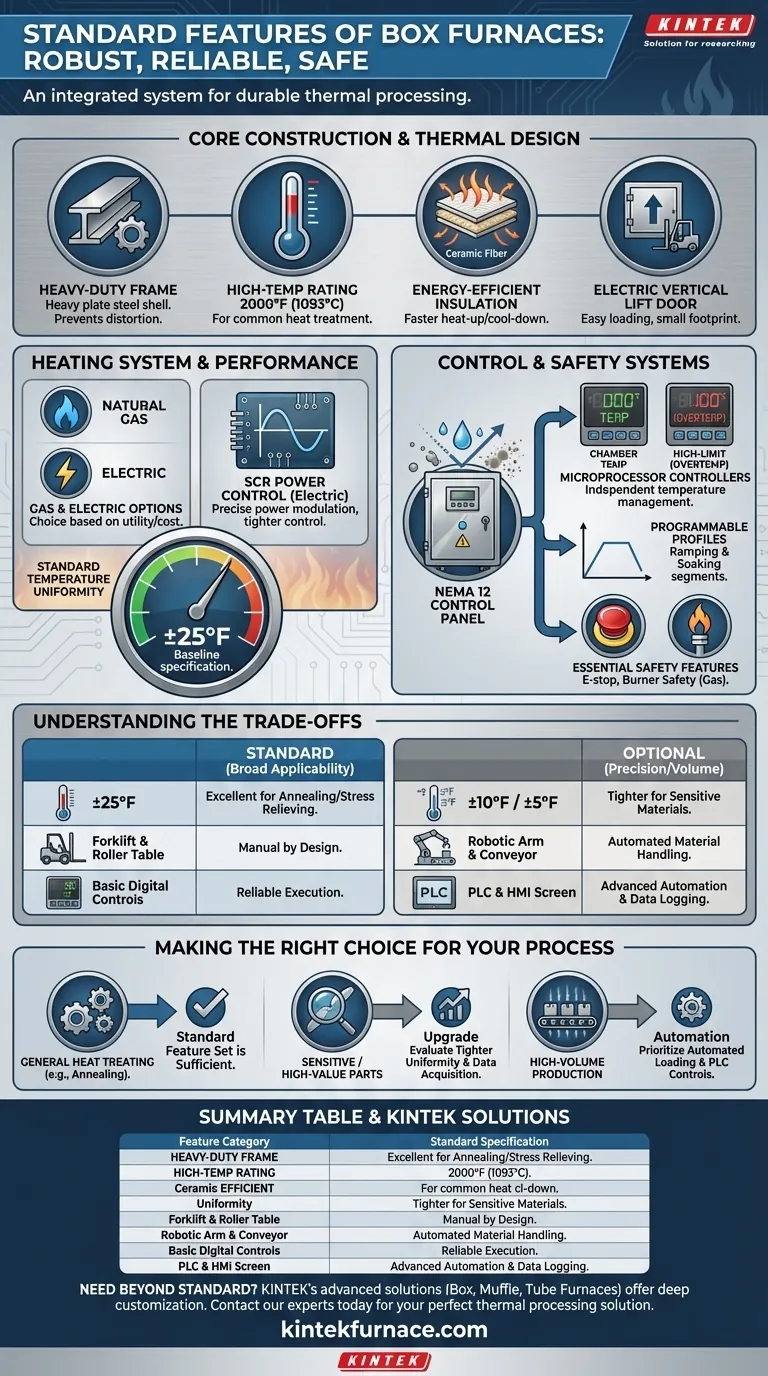

Core Construction & Thermal Design

The physical design of a Box Furnace is foundational to its performance and longevity. The standard features are engineered to withstand heavy loads and repeated thermal cycling.

Heavy-Duty Frame and Casing

The furnace is built with a heavy plate steel shell designed to accept heavy workloads. This rigid construction prevents distortion under high temperatures and the stress of loading and unloading.

High-Temperature Rating

A common standard rating for these furnaces is 2000°F (1093°C). This capability makes them suitable for a wide variety of common heat treatment processes.

Energy-Efficient Insulation

To maintain temperature and reduce energy consumption, Box Furnaces use high-density, energy-saving ceramic fiber insulation. This material offers excellent thermal performance and faster heat-up and cool-down times compared to traditional brick.

Door Mechanism

The most common standard is an electric vertical lift door. This design provides easy access for loading with a forklift while minimizing the shop floor footprint required for operation.

Heating System & Performance

The method of heating and the precision of its control are critical to achieving the desired metallurgical or material properties.

Gas and Electric Options

Box Furnaces are available in both natural gas-fired and electrically heated versions. The choice depends on utility availability, operating cost, and specific process requirements.

SCR Power Control (Electric Models)

Standard electric furnaces utilize Silicon Controlled Rectifier (SCR) power controls. This technology precisely modulates the power sent to the heating elements, avoiding the temperature swings associated with simple on/off contactors and enabling tighter control.

Standard Temperature Uniformity

A typical baseline performance specification is a temperature uniformity of ±25°F within the workspace. While suitable for many general-purpose applications, this is a key specification to check against your process needs.

Control and Safety Systems

The control panel is the operational heart of the furnace, ensuring the process runs accurately, repeatably, and safely.

NEMA 12 Control Panel

Furnaces come standard with a machine-mounted NEMA 12 rated control panel. This enclosure protects the electrical components from circulating dust, falling dirt, and dripping non-corrosive liquids.

Microprocessor-Based Controllers

Two separate microprocessor-based temperature controllers are standard: one for managing the furnace chamber temperature and a second, independent controller for high-limit overtemperature protection.

Programmable Profiles

These digital controllers typically allow for programming simple multi-segment heat profiles, such as ramping to a specific temperature, soaking for a set duration, and then cooling.

Essential Safety Features

A prominent, single-button Emergency Stop (E-stop) is a standard feature on the control panel. Gas-fired models also include mandatory burner safety and flame supervision equipment.

Understanding the Trade-offs

The standard feature set is designed for broad applicability and value, but it's crucial to understand its inherent limitations.

Standard Uniformity vs. Precision Needs

The standard ±25°F uniformity is excellent for processes like annealing or stress relieving. However, for sensitive materials or demanding specifications (e.g., aerospace), an optional tighter uniformity of ±10°F or even ±5°F may be necessary.

Manual Loading by Design

The robust piers and optional hearth are built to be loaded manually, typically with a forklift or a roller table. Fully automated loading and material handling systems are specialized, optional features.

Basic Controls vs. Advanced Automation

Standard controllers execute the heating profile reliably. However, for process automation, advanced data logging, or integration with factory-wide systems, an upgrade to a Programmable Logic Controller (PLC) with an HMI is required.

Making the Right Choice for Your Process

Use this breakdown of standard features as a baseline to define what you truly need from the equipment.

- If your primary focus is general heat treating (annealing, tempering): The standard feature set, including microprocessor controls and ±25°F uniformity, is typically sufficient for reliable and repeatable results.

- If your primary focus is processing high-value or sensitive parts: You should carefully evaluate optional upgrades for tighter temperature uniformity and consider adding a data acquisition system for process validation.

- If your primary focus is high-volume production: Prioritize optional features that facilitate throughput, such as hearth roller rails, integrated load tables, and PLC/HMI controls for process automation.

Understanding these standard features provides a solid foundation for specifying a Box Furnace that precisely meets your operational and quality requirements.

Summary Table:

| Feature Category | Standard Specification |

|---|---|

| Max Temperature | 2000°F (1093°C) |

| Construction | Heavy plate steel shell |

| Insulation | High-density ceramic fiber |

| Door Type | Electric vertical lift |

| Temperature Control | Microprocessor-based with SCR (Electric) |

| Standard Uniformity | ±25°F |

| Safety | Emergency Stop, Overtemperature Protection |

| Control Panel | NEMA 12 Rated |

Need a furnace that goes beyond the standard? KINTEK's advanced high-temperature solutions, including our Box, Muffle, and Tube Furnaces, are engineered with deep customization capabilities to meet your unique process requirements. Leverage our exceptional R&D and in-house manufacturing to get a system with precise temperature uniformity, advanced automation, or specialized configurations. Contact our experts today to discuss how we can build the perfect thermal processing solution for your lab.

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation