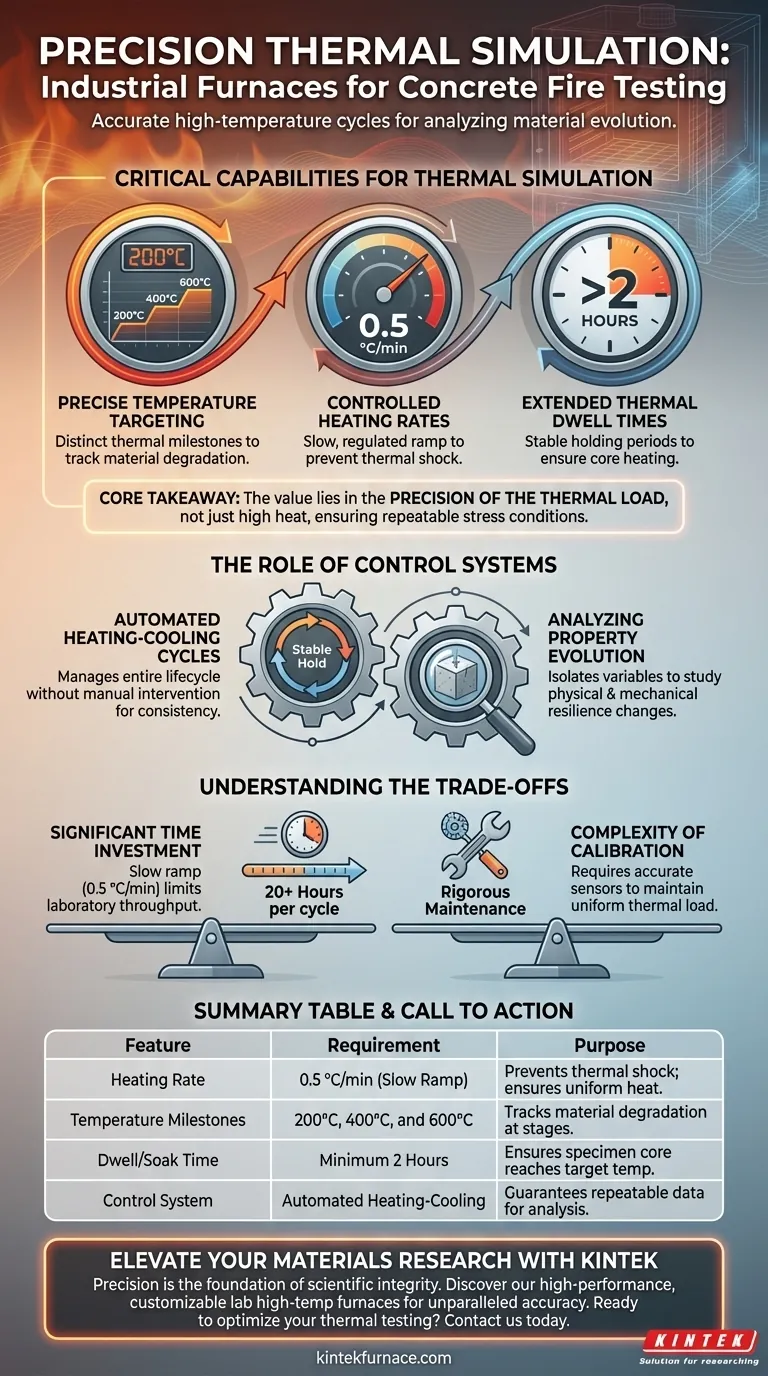

To accurately simulate high-temperature fire cycles for concrete testing, an industrial-grade electric furnace must perform precise heating-cooling sequences rather than simple unregulated heating. Specifically, the equipment requires a sophisticated control system capable of maintaining a slow heating rate of 0.5 °C/min, reaching distinct temperature plateaus of 200°C, 400°C, and 600°C, and holding these temperatures stable for at least 2 hours.

Core Takeaway: The value of these furnaces lies not just in reaching high heat, but in the precision of the thermal load. To effectively study the evolution of physical and mechanical properties in recycled concrete, the furnace must execute rigorous, automated cycles that ensure every test specimen undergoes the exact same stress conditions.

Critical Capabilities for Thermal Simulation

To replicate the stress of fire conditions for research purposes, the furnace must bridge the gap between raw power and delicate control.

Precise Temperature Targeting

The furnace must be capable of reaching and stabilizing at specific thermal milestones.

Standard testing protocols for concrete require data points at 200°C, 400°C, and 600°C. These distinct steps allow researchers to track how material properties degrade as heat intensity increases.

Controlled Heating Rates

A critical function is the ability to regulate the speed of temperature increase.

The furnace must support a slow, steady heating rate, specifically 0.5 °C/min. This slow ramp-up is essential for ensuring the heat penetrates the concrete uniformly without causing premature failure due to rapid thermal shock before the target temperature is reached.

Extended Thermal Dwell Times

Reaching the target temperature is only half the battle; the furnace must maintain it.

The system must hold the target temperature constant for extended periods, typically 2 hours. This "soaking" period ensures the concrete is thoroughly heated to the core, allowing for valid measurements of property evolution.

The Role of Control Systems

The difference between a standard kiln and an industrial-grade testing furnace is the sophistication of the control architecture.

Automated Heating-Cooling Cycles

The furnace must manage the entire lifecycle of the test without manual intervention.

This includes executing the ramp-up, the stable hold, and the cooling phase. Consistency in these cycles is vital for producing comparable data across multiple samples.

Analyzing Property Evolution

The ultimate function of these controls is to enable the study of recycled concrete under extreme thermal loads.

By strictly controlling the environment, researchers can isolate variables to see exactly how physical and mechanical resilience changes after exposure to fire conditions.

Understanding the Trade-offs

While high-precision furnaces are necessary for valid scientific data, they introduce specific operational constraints that must be managed.

Significant Time Investment

The requirement for a 0.5 °C/min heating rate inherently dictates very long test durations.

To reach 600°C at this rate requires 20 hours of ramp-up time alone, plus the 2-hour hold. This limits the throughput of the laboratory, as only one cycle can be completed per day.

Complexity of Calibration

Sophisticated control systems require rigorous maintenance to ensure accuracy.

If the heating elements or sensors drift even slightly, the heating rate may fluctuate. This would invalidate the data regarding the mechanical evolution of the concrete, as the thermal load would no longer be uniform.

Making the Right Choice for Your Research

When selecting or configuring a furnace for concrete fire simulation, align the specifications with your data requirements.

- If your primary focus is mechanical property analysis: Prioritize a control system that guarantees a stable 2-hour dwell time to ensure the sample is heated uniformly to its core.

- If your primary focus is thermal shock avoidance: Ensure the heating elements can maintain the slow 0.5 °C/min ramp rate without fluctuation to prevent sample cracking during the ramp-up.

The integrity of your research depends on the furnace's ability to turn chaotic fire conditions into a measurable, repeatable scientific process.

Summary Table:

| Feature | Requirement for Concrete Testing | Purpose in Fire Simulation |

|---|---|---|

| Heating Rate | 0.5 °C/min (Slow Ramp) | Prevents thermal shock; ensures uniform heat penetration. |

| Temperature Milestones | 200°C, 400°C, and 600°C | Tracks material degradation at specific fire stages. |

| Dwell/Soak Time | Minimum 2 Hours | Ensures the specimen core reaches the target temperature. |

| Control System | Automated Heating-Cooling | Guarantees repeatable data for physical/mechanical analysis. |

Elevate Your Materials Research with KINTEK

Precision is the foundation of scientific integrity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to meet the rigorous demands of industrial fire cycle simulation.

Whether you are analyzing the mechanical evolution of recycled concrete or testing advanced ceramics, our customizable lab high-temp furnaces provide the stable ramp rates and precise dwell times your research requires.

Ready to optimize your thermal testing? Contact us today to discuss your unique testing needs and discover how our specialized heating solutions can bring unparalleled accuracy to your laboratory.

Visual Guide

References

- N. Algourdin, Amir Si Larbi. High temperature performance of recycled fine concrete. DOI: 10.1007/s44242-024-00050-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What factors should be considered when selecting a location for a benchtop furnace? Ensure Safety and Efficiency in Your Lab

- How long does it take for a muffle furnace to reach its maximum temperature? Optimize Your Lab's Heating Process

- How are muffle furnaces utilized in high-temperature sintering within the pharmaceutical industry? Unlock Precision in Drug Delivery and Implants

- What role does a muffle furnace play in pharmaceuticals? Ensuring Purity and Precision in Drug Development

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- How does muffle furnace calcination at 900°C for 13 hours form P2-type cathode structures?

- How does a laboratory muffle furnace facilitate the pyrolysis of Plum Stone Biochar? Optimize Your Carbon Production

- How does a high-precision resistance furnace ensure T6 solution treatment? Achieve Peak Alloy Strength with KINTEK