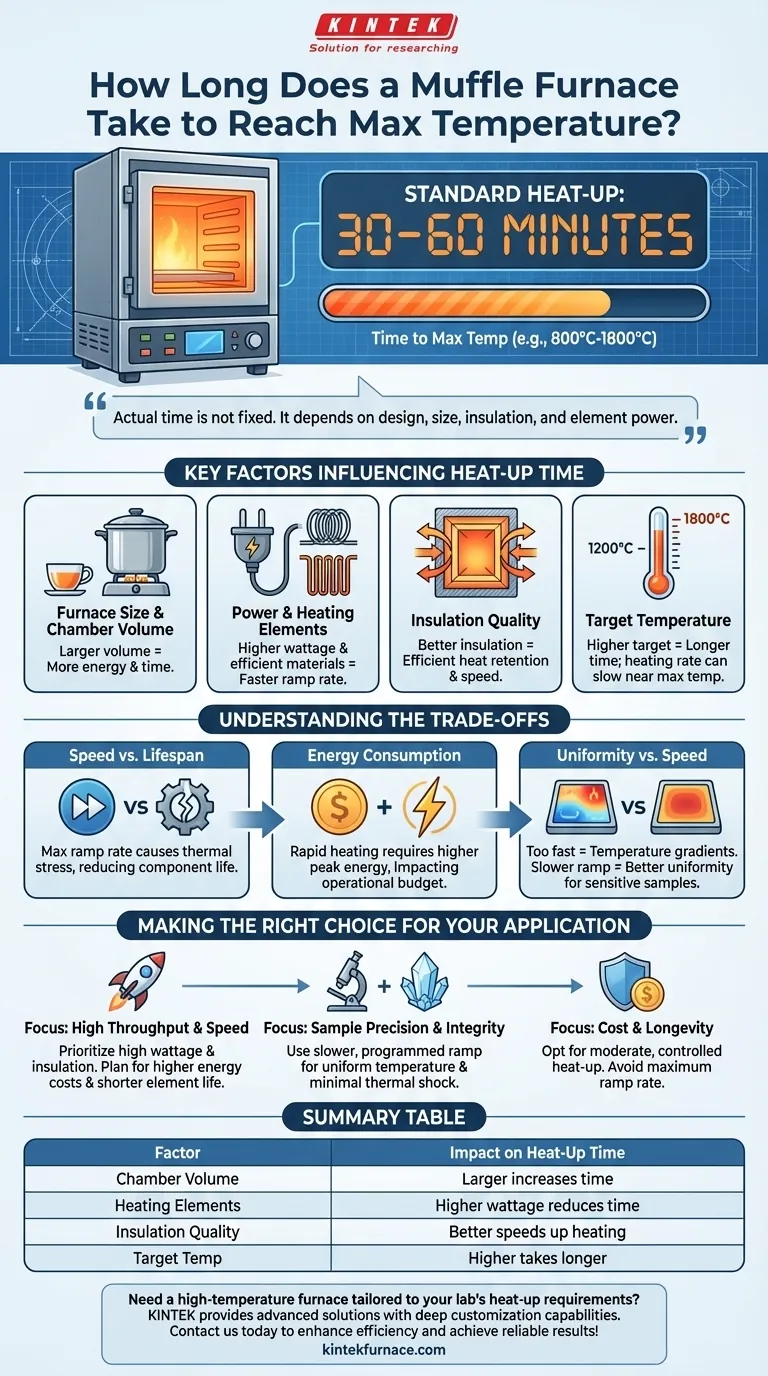

The time required for a muffle furnace to reach its maximum temperature is a critical operational parameter. For most standard laboratory models, you can expect a heat-up time of 30 to 60 minutes. Larger, industrial-grade furnaces or those with more advanced capabilities may require a significantly longer period to safely and uniformly reach their peak operating temperature, which can range from 800°C to 1800°C.

While a 30-to-60-minute estimate is a useful rule of thumb, the actual heat-up time is not a fixed number. It is a direct result of the furnace's design, including its size, insulation quality, and the power of its heating elements.

Key Factors Influencing Heat-Up Time

Understanding why this time varies is essential for planning experiments, managing energy costs, and ensuring the longevity of your equipment. Several core factors are at play.

Furnace Size and Chamber Volume

The internal volume of the furnace chamber is the most straightforward variable. A larger space simply requires more energy and thus more time to heat to a uniform temperature.

Think of it like boiling water: a small cup will boil much faster on the same stove than a large stockpot.

Power and Type of Heating Elements

The power output (wattage) and material of the heating elements directly dictate the furnace's ramp rate—the speed at which it can increase the temperature.

Furnaces with higher-wattage elements will heat up faster. The material of the element (e.g., Kanthal, Silicon Carbide) also determines its maximum temperature and efficiency.

Insulation Quality and Material

Insulation is what keeps the heat inside the furnace. High-quality ceramic fiber or refractory brick insulation minimizes heat loss to the surrounding environment.

Better insulation means the energy from the heating elements is used more efficiently to raise the chamber temperature, resulting in a faster heat-up time and better stability at the target temperature.

The Target Temperature

It is an obvious but important factor: reaching 1200°C will take less time than reaching 1800°C in the same furnace.

Furthermore, the rate of heating is not always linear. A furnace may heat very quickly to 1000°C but then slow down significantly as it approaches its absolute maximum operating temperature.

Understanding the Trade-offs

Choosing or operating a furnace based on its heat-up speed involves important trade-offs that impact cost, precision, and equipment lifespan.

Speed vs. Equipment Lifespan

Consistently pushing a furnace to its maximum ramp rate can create significant thermal stress on both the heating elements and the ceramic refractory materials inside.

This rapid expansion and contraction can reduce the operational life of these components, leading to more frequent and costly maintenance.

Energy Consumption

A furnace designed for rapid heating requires higher-power heating elements. While this achieves your target temperature faster, it comes at the cost of higher peak energy consumption.

This can have a substantial impact on your laboratory's or facility's operational budget, especially with frequent use.

Temperature Uniformity vs. Speed

Heating a chamber too quickly can create temperature gradients, where the areas near the elements are much hotter than the center of the chamber.

For sensitive applications like annealing, ashing, or crystal growth, a slower, controlled ramp-up is often necessary to ensure the entire sample experiences a uniform temperature.

Making the Right Choice for Your Application

Your optimal heat-up strategy should be determined by the primary goal of your process.

- If your primary focus is high throughput and speed: Prioritize a furnace with high-wattage elements and excellent insulation, but plan for higher energy costs and a shorter element lifespan.

- If your primary focus is sample precision and process integrity: Utilize a slower, programmed ramp rate to ensure excellent temperature uniformity and minimize thermal shock to your materials.

- If your primary focus is operational cost and equipment longevity: Avoid using the maximum possible ramp rate for every cycle and opt for a more moderate, controlled heat-up schedule.

Ultimately, treating the heat-up time not as a fixed delay but as a controllable process variable will give you the most reliable and efficient results.

Summary Table:

| Factor | Impact on Heat-Up Time |

|---|---|

| Furnace Size and Chamber Volume | Larger volumes increase time due to more energy needed |

| Power and Type of Heating Elements | Higher wattage and efficient materials reduce time |

| Insulation Quality | Better insulation speeds up heating and improves stability |

| Target Temperature | Higher temperatures generally take longer to reach |

Need a high-temperature furnace tailored to your lab's specific heat-up requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise performance for your unique experiments. Contact us today to enhance your efficiency and achieve reliable results!

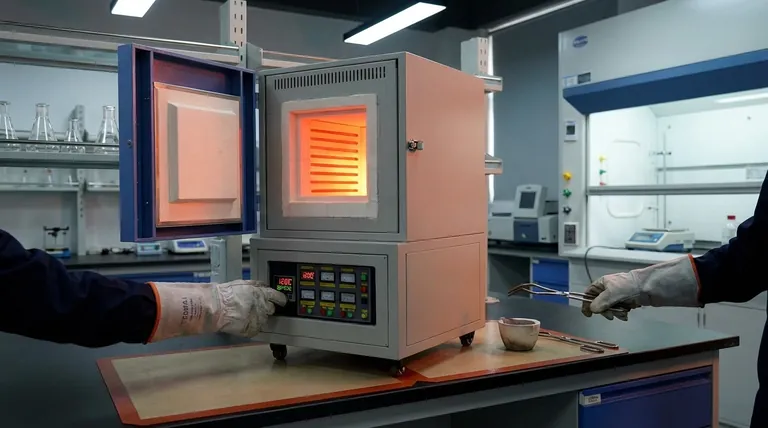

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?