Selecting the right location for a benchtop furnace is a critical decision that directly impacts safety, operational efficiency, and the longevity of the equipment. The primary factors to consider are ventilation, clearance from flammable materials, accessibility for maintenance, and placement away from high-traffic areas and emergency exits.

The location of your furnace is not just a matter of convenience; it is the foundation of a safe and effective thermal processing system. Proper placement mitigates fire risk, protects personnel, and ensures the equipment can operate reliably according to its design specifications.

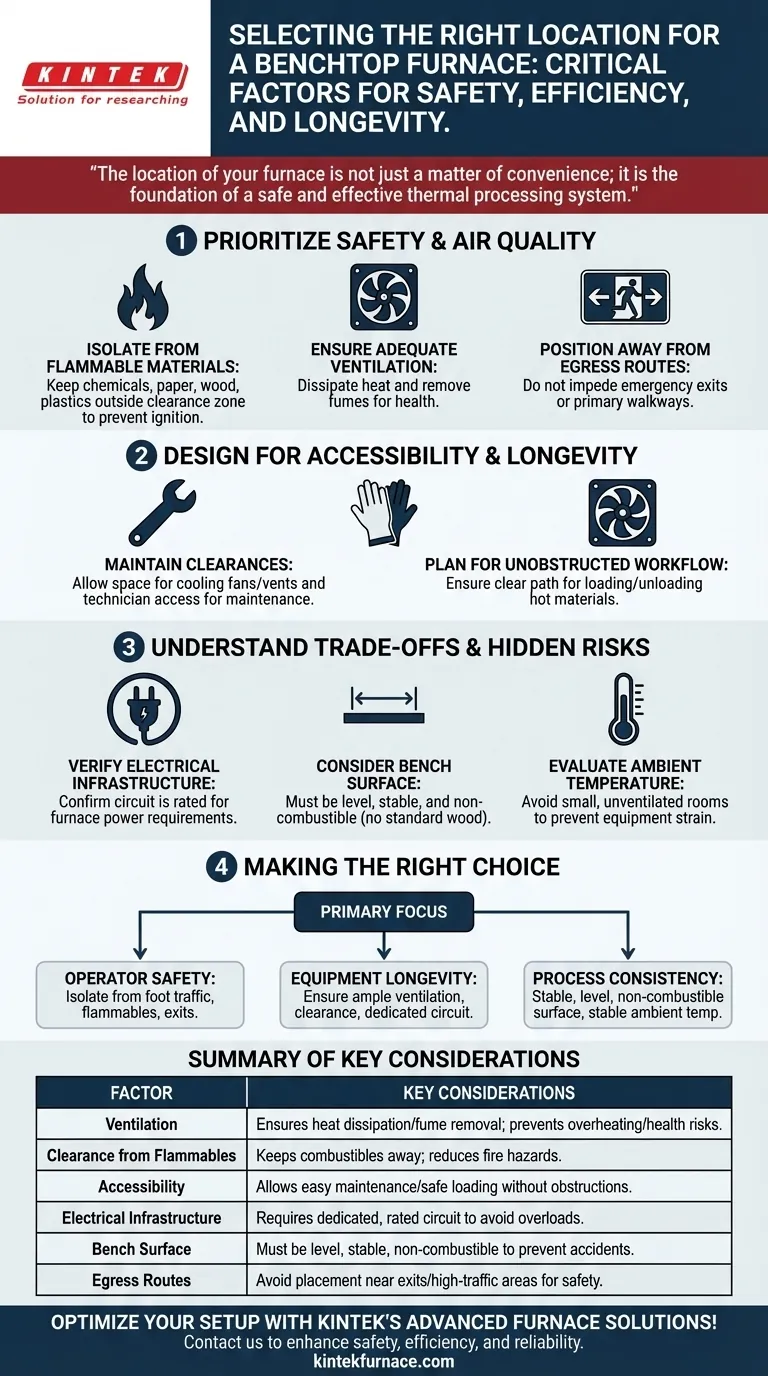

Prioritizing Safety and Air Quality

The most immediate risks associated with a furnace are intense heat and potential fumes. Your first priority must be to control these hazards by carefully managing the surrounding environment.

Isolate from Flammable Materials

A furnace radiates significant heat. All combustible or flammable materials—including chemicals, paper, wood, and plastics—must be kept far outside the manufacturer's recommended clearance zone. This prevents ignition from both direct contact and radiant heat.

Ensure Adequate Ventilation

Proper ventilation is non-negotiable. It serves two purposes: it dissipates the ambient heat generated by the furnace, preventing the room from overheating, and it removes any potential fumes or off-gassing from your process materials, protecting the operator's respiratory health.

Position Away from Egress Routes

The furnace must never be located where it could impede an emergency exit or be an obstacle in a primary walkway. In the event of an emergency, clear and unobstructed egress paths are essential for personnel safety.

Designing for Accessibility and Longevity

Beyond immediate safety, the furnace's location affects its day-to-day usability and long-term health. A poorly placed unit is difficult to use and prone to premature failure.

Maintain Clearances for Cooling and Maintenance

Furnaces have vents and fans to cool their internal electronics and outer casing. Blocking these clearances by placing the unit too close to a wall or other equipment can cause it to overheat, leading to component failure and inaccurate temperature control.

Ensure there is sufficient space around the unit for a technician to comfortably and safely perform routine maintenance and repairs.

Plan for an Unobstructed Workflow

Consider how operators will interact with the furnace. There should be a clear, safe path for loading and unloading materials without having to reach over other equipment or navigate tight spaces, especially while handling hot items with personal protective equipment (PPE).

Understanding the Trade-offs and Hidden Risks

Seemingly minor oversights during installation can lead to significant problems. Acknowledging the hidden risks is key to a truly safe and functional setup.

Verify Electrical Infrastructure

Benchtop furnaces are high-draw appliances. Confirm that the electrical circuit you plan to use is rated for the furnace's power requirements. An overloaded circuit is a serious fire hazard and can cause performance issues.

Consider the Bench Surface

The bench or table supporting the furnace must be perfectly level, stable, and made of a non-combustible material. A standard wooden workbench is often unsuitable. The surface must be able to support the furnace's weight without any risk of tipping or collapse.

Evaluate Ambient Temperature Impact

Placing a furnace in a small, unventilated room will not only make the space uncomfortable but will also force the furnace's cooling systems to work harder. This added strain can reduce the lifespan of critical components.

Making the Right Choice for Your Goal

Your specific priorities will guide your final decision. Use this framework to determine the best location for your application.

- If your primary focus is operator safety: Prioritize isolating the furnace from all foot traffic, flammable materials, and emergency exits.

- If your primary focus is equipment longevity: Ensure the location provides ample ventilation and clearance on all sides, and that it is connected to a dedicated, properly rated electrical circuit.

- If your primary focus is process consistency: Choose a stable, level, non-combustible surface in an area with minimal ambient temperature fluctuation.

Ultimately, a well-chosen location transforms a powerful tool into a safe, reliable, and productive asset for your workspace.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Ventilation | Ensures heat dissipation and fume removal; prevents overheating and health risks. |

| Clearance from Flammables | Keeps combustible materials away to reduce fire hazards from radiant heat. |

| Accessibility | Allows easy maintenance and safe loading/unloading without obstructions. |

| Electrical Infrastructure | Requires a dedicated, properly rated circuit to avoid overloads and ensure reliability. |

| Bench Surface | Must be level, stable, and non-combustible to support weight and prevent accidents. |

| Egress Routes | Avoids placement near exits or high-traffic areas for emergency safety. |

Optimize your laboratory setup with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our strong deep customization capability ensures precise performance for diverse applications. Contact us today to enhance safety, efficiency, and reliability in your workspace!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals