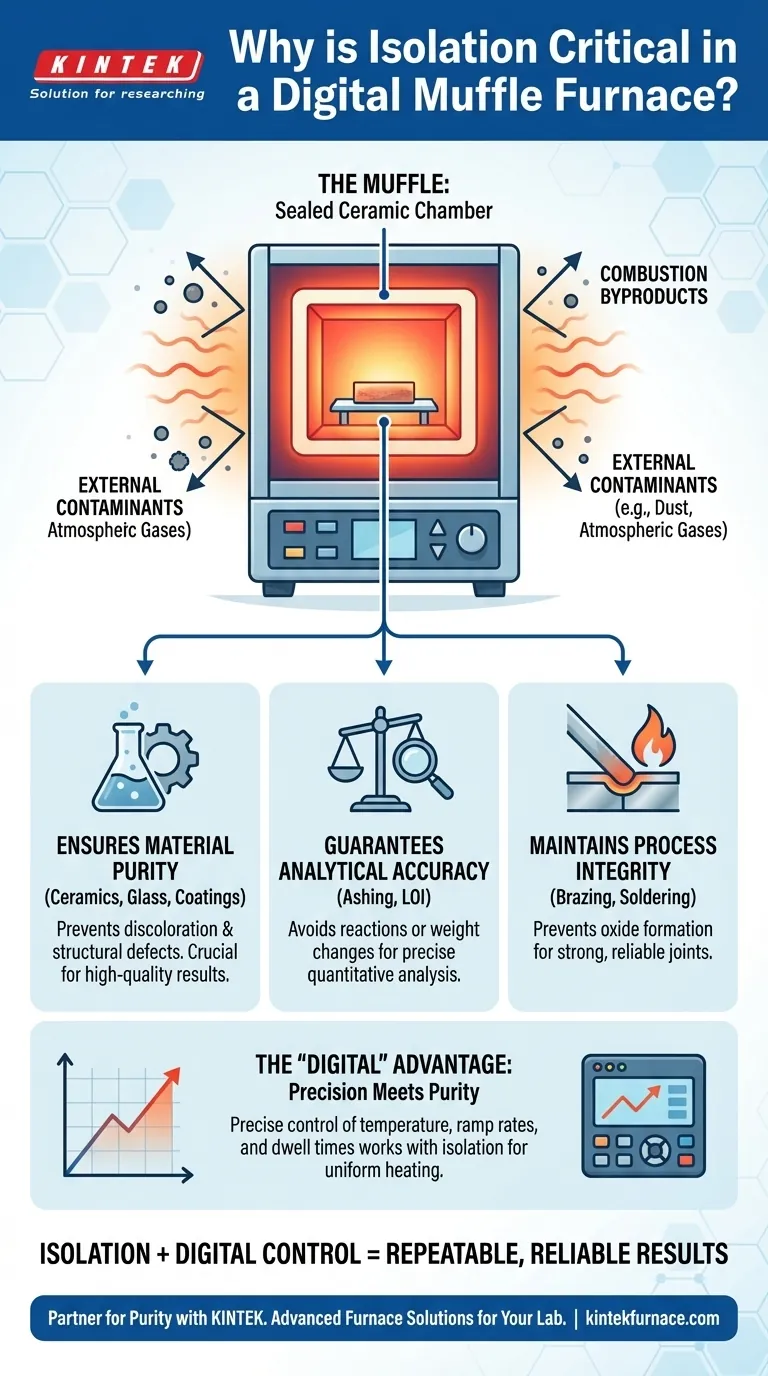

In a digital muffle furnace, isolation is the defining feature that guarantees process integrity. It is critical because it creates a sealed chamber that separates your sample from combustion byproducts and external atmospheric contaminants. This prevents unwanted chemical reactions, ensuring the final material's purity, analytical accuracy, and structural quality are not compromised.

The core value of a muffle furnace is not just its ability to generate high temperatures, but its ability to do so within a chemically clean environment. Isolation ensures that the only variable affecting your sample is the intended heat profile, leading to pure, predictable, and repeatable results.

The Core Principle: Separating the Heat Source from the Sample

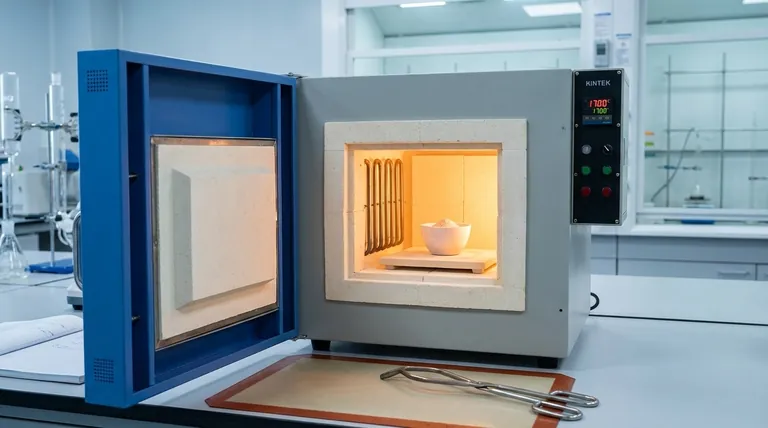

A muffle furnace's name comes from its central component: the muffle. This is a refractory ceramic chamber that contains the sample. The heating elements (or in older designs, the fuel combustion) are located outside this chamber.

What is a "Muffle"?

A muffle is essentially a box-like enclosure that acts as a physical barrier. Heat radiates through the walls of the muffle to heat the sample inside, but gases and particulates from the heating process cannot enter.

Why Combustion Byproducts Are a Problem

In fuel-fired furnaces, combustion creates byproducts like carbon, sulfur compounds, and other reactive gases. If these were to contact the sample, they could cause unintended chemical reactions, discoloration, or structural impurities.

Electric muffle furnaces eliminate combustion byproducts, but the principle of isolation remains vital for protecting the sample from the outside environment.

Preventing External Contamination

The sealed chamber of the muffle also prevents contaminants from the surrounding lab environment, such as dust or atmospheric gases, from interfering with the process. This is critical for sensitive applications where even trace amounts of foreign material can invalidate the results.

The Impact of Contamination Across Applications

Failing to isolate a sample can have catastrophic effects on the outcome of a process, rendering the results useless or the final product defective.

For Material Purity (Ceramics, Coatings, Glass)

When creating technical ceramics, enamel coatings, or melting glass, purity is paramount. Contaminants can introduce discoloration, create weak spots in the material's structure, or prevent proper adhesion of a coating.

For Analytical Accuracy (Ashing & LOI)

Processes like ashing or Loss on Ignition (LOI) are used to determine the inorganic content of a sample by burning off the organic matter. If external contaminants are introduced, they can either react with the sample or add to its final weight, making the quantitative analysis completely inaccurate.

For Process Integrity (Brazing & Soldering)

In high-temperature metal joining processes like brazing, oxides and other contaminants can form on the surface, preventing the filler material from properly wetting and bonding to the parent metals. This results in a weak or failed joint.

The "Digital" Advantage: Precision Meets Purity

While isolation handles the chemical environment, the digital controller manages the thermal environment. The two work together to deliver a highly controlled process.

Temperature as a Critical Variable

The digital interface allows for precise control over temperature, ramp rates (how quickly the temperature rises), and dwell times (how long it stays at a specific temperature). This ensures uniform heating and prevents thermal shock to the material.

Ensuring Repeatable Results

For quality control or scientific research, repeatability is non-negotiable. The combination of a contaminant-free environment (from isolation) and a precisely programmed heating cycle (from the digital controller) means you can run the exact same process over and over with confidence.

Making the Right Choice for Your Goal

Understanding the role of isolation helps you leverage the muffle furnace for your specific needs.

- If your primary focus is material creation (ceramics, glass): Your goal is to use the furnace's isolation to prevent chemical impurities that cause structural or aesthetic defects in your final product.

- If your primary focus is quantitative analysis (ashing, LOI): Your goal is to rely on the sealed chamber to guarantee that the only mass change you measure comes from your sample, not from reactions with outside elements.

- If your primary focus is process repeatability (research, QC): Your goal is to combine the furnace's physical isolation with its digital precision to create a stable, reproducible environment that is essential for valid results.

Ultimately, the isolation within a muffle furnace provides control, ensuring your outcome is a product of your intended process, not random contamination.

Summary Table:

| Application | Impact of Isolation |

|---|---|

| Material Purity (Ceramics, Glass) | Prevents discoloration and structural defects by blocking contaminants |

| Analytical Accuracy (Ashing, LOI) | Ensures precise measurements by avoiding external interference |

| Process Integrity (Brazing, Soldering) | Promotes strong joints by preventing oxide formation and contamination |

| General Use | Provides a chemically clean environment for repeatable, reliable outcomes |

Need a contaminant-free solution for your lab? At KINTEK, we specialize in advanced high-temperature furnaces tailored to your needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise solutions for unique experimental requirements. Contact us today to enhance your process integrity and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation