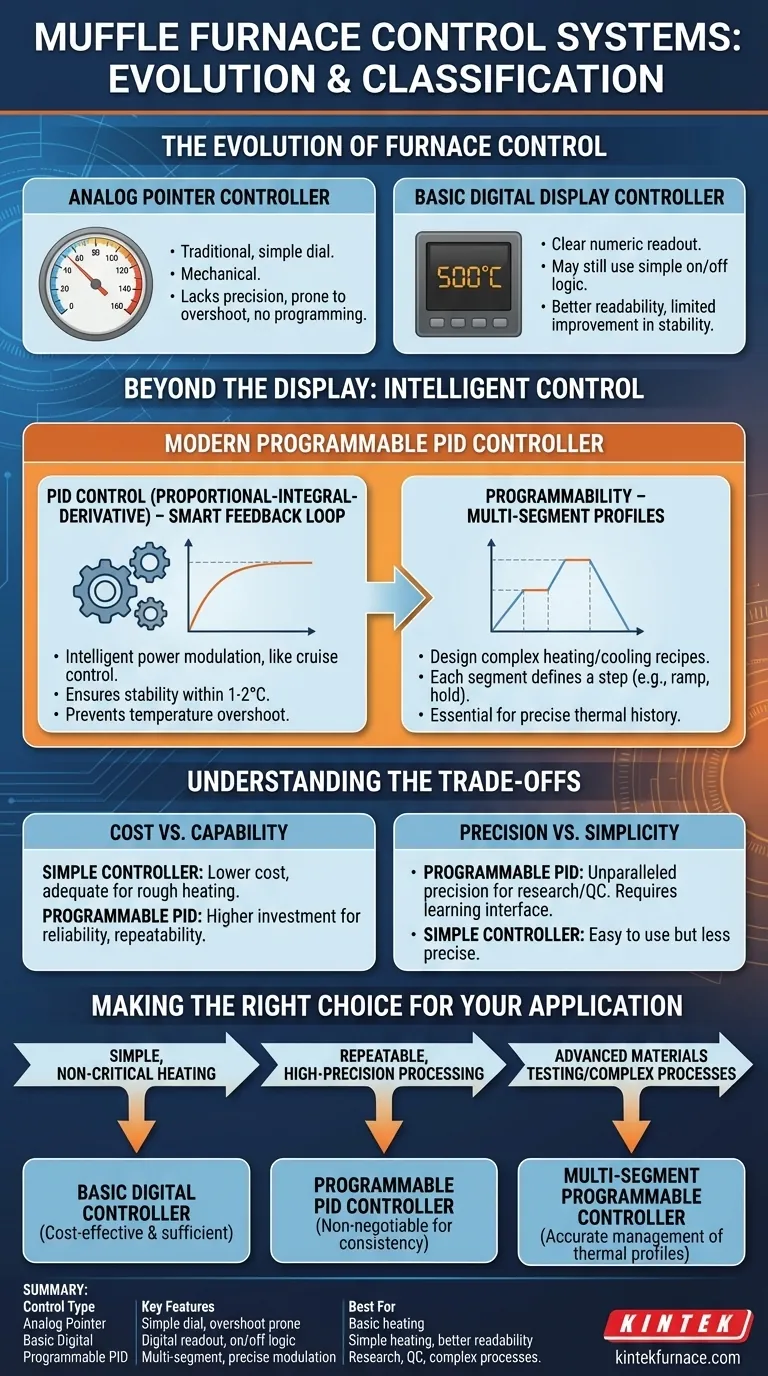

At its most basic level, a muffle furnace's control device classification comes down to its user interface. The primary distinction is between older analog "pointer" displays and more modern digital displays. This classification, however, only scratches the surface of what truly differentiates furnace control systems.

While the surface classification separates analog and digital displays, the critical distinction for performance is the underlying control logic. The real choice is between simple single-setpoint control and advanced, multi-segment programmable PID control that enables precise and repeatable thermal processing.

The Evolution of Furnace Control

The way we command a muffle furnace to perform its task has evolved significantly. This evolution directly impacts the precision, repeatability, and complexity of the heat-treatment processes you can achieve.

The Analog Pointer Controller

This is the most traditional form of control. Think of it as a simple dial you turn to a desired temperature marked on a scale.

A needle, or pointer, indicates the current temperature inside the chamber. These systems are purely mechanical or use very simple electronics.

While functional for basic heating, they lack precision, are prone to temperature overshooting, and offer no ability to program heating rates or dwell times.

The Basic Digital Display Controller

The introduction of digital displays was a significant step up in user experience, providing a clear, numeric readout of the temperature.

However, an early "digital" controller might simply replace the analog dial and pointer with a digital setpoint and readout. The underlying control logic could still be a rudimentary on/off system.

This offers better readability but may not provide a significant improvement in temperature stability or process control over its analog predecessor.

Understanding Modern Programmable Controllers

The true advancement in muffle furnace technology lies not in the display, but in the intelligence of the controller behind it. Modern furnaces rely on sophisticated systems to execute complex thermal profiles with high accuracy.

The Role of PID Control

Nearly all high-quality modern furnaces use PID (Proportional-Integral-Derivative) automatic control. This is a smart feedback loop system.

Instead of simply turning the heater on at full power until the setpoint is reached (which causes overshoot), a PID controller intelligently modulates the power.

Think of it like an expert driver using cruise control. It doesn't just floor the gas and then slam the brakes; it makes constant, tiny adjustments to the accelerator to maintain a perfectly steady speed. PID control does this for temperature, ensuring stability within one or two degrees of your setpoint.

The Power of Programmability

Modern controllers are also fully programmable. References to "30-segment programmable control" mean you can design a complex heating and cooling recipe.

Each "segment" is a step in the process, such as "ramp up to 500°C over 60 minutes," "hold at 500°C for 90 minutes," or "cool down to 100°C over 3 hours."

This capability is essential for materials science, specific ashing protocols, and any process that requires a precise thermal history, not just a single peak temperature.

Understanding the Trade-offs

Choosing a control system involves balancing cost against the needs of your application. An incorrect choice can lead to failed processes and inconsistent results.

Cost vs. Capability

A furnace with a simple, non-programmable digital controller will be significantly less expensive. For applications where you just need to heat an object to a rough temperature, this can be a perfectly adequate and cost-effective choice.

However, the investment in a programmable PID controller pays for itself in reliability and repeatability for any sensitive or documented work.

Precision vs. Simplicity

Programmable controllers offer unparalleled precision. They ensure that a process run today is identical to one run six months from now, which is critical for research and quality control.

The trade-off is a slightly higher learning curve. You must learn the interface to input the desired segments of your heating profile, though modern interfaces are increasingly user-friendly.

The Pitfall of an Application Mismatch

The most common mistake is using a furnace with a basic controller for an application that requires a precise thermal profile. Attempting complex heat-treatments or specific ashing procedures without programmable control will lead to inconsistent and unreliable outcomes.

Making the Right Choice for Your Application

The control system dictates the furnace's capabilities. Select the controller that matches the complexity and precision your work demands.

- If your primary focus is simple, non-critical heating to a single temperature: A basic digital controller will be a cost-effective and sufficient solution.

- If your primary focus is repeatable, high-precision processing for research or quality control: A programmable PID controller is non-negotiable for achieving consistent and reliable results.

- If your primary focus is advanced materials testing or complex chemical processes: You must select a multi-segment programmable controller to accurately manage heating rates, dwell times, and cooling profiles.

Ultimately, understanding the control system empowers you to select a furnace that doesn't just get hot, but performs the exact thermal process your work requires.

Summary Table:

| Control Type | Key Features | Best For |

|---|---|---|

| Analog Pointer | Simple dial, mechanical, prone to overshoot | Basic, non-critical heating |

| Basic Digital | Digital readout, may use on/off logic | Simple heating with better readability |

| Programmable PID | Multi-segment control, precise modulation, high stability | Research, quality control, complex processes |

Upgrade your lab's thermal processing with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior precision and repeatability. Contact us today to discuss how our furnaces can enhance your results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production