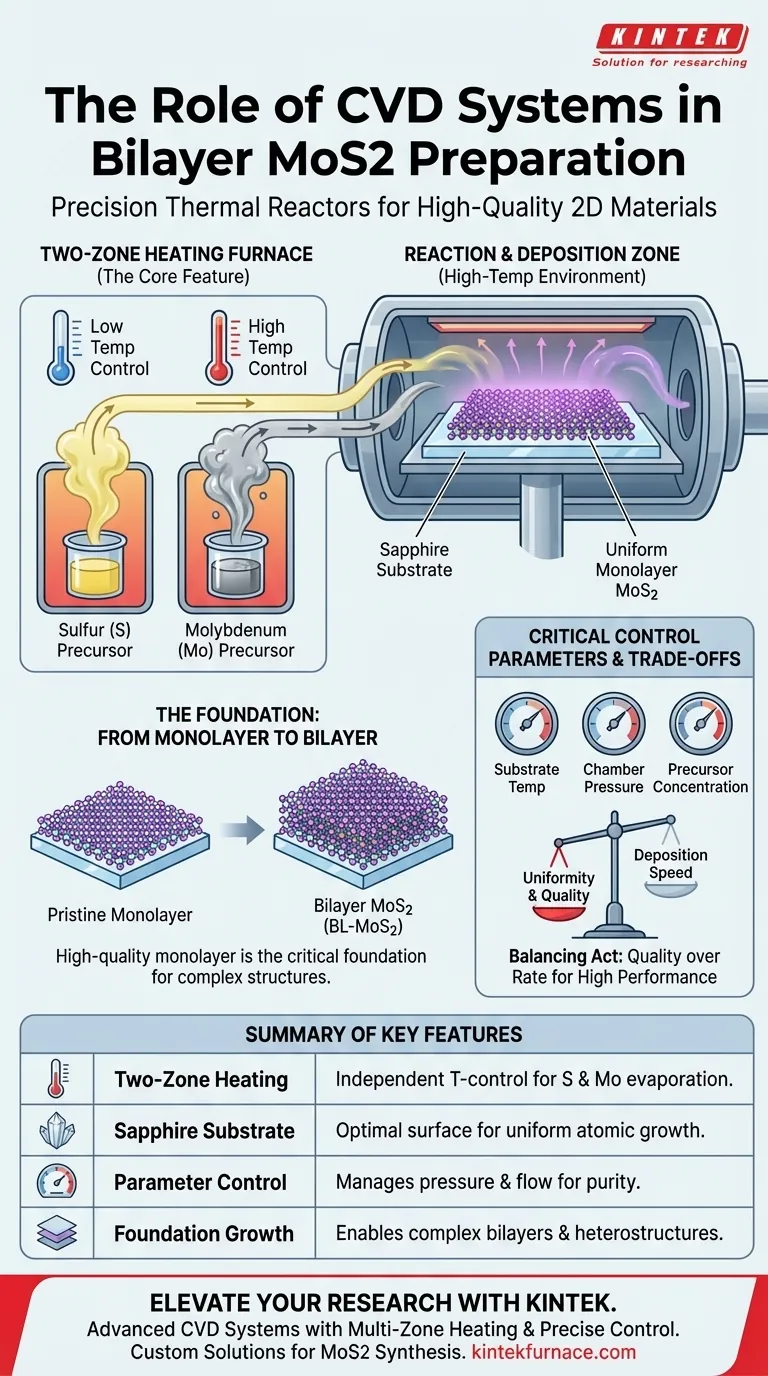

The Chemical Vapor Deposition (CVD) system functions as a precision thermal reactor designed to synthesize high-quality molybdenum disulfide (MoS2) from solid precursors. Its primary role is to provide a strictly controlled high-temperature environment where solid sulfur and molybdenum sources can vaporize, react, and deposit onto a sapphire substrate to form uniform atomic layers.

Core Takeaway The CVD system’s defining feature in this process is its two-zone heating furnace, which allows for independent temperature control over the evaporation of different source materials. This isolation ensures the growth of large-area, high-quality MoS2 layers, serving as the critical structural foundation necessary for creating bilayers and complex heterostructures.

The Mechanics of MoS2 Synthesis

Precision via Two-Zone Heating

The central challenge in growing MoS2 is that sulfur and molybdenum have vastly different melting and evaporation points. A standard single-zone furnace cannot optimally manage both simultaneously.

The CVD system solves this by utilizing a two-zone heating furnace. This configuration allows the system to independently control the evaporation temperatures of the solid sulfur and molybdenum precursors.

Reaction on the Substrate

Once evaporated, the gaseous precursors travel to the deposition zone. Here, the CVD system maintains a specific high-temperature environment that facilitates the chemical reaction.

The precursors react specifically on sapphire substrates. The result is the formation of molybdenum disulfide layers with uniform atomic thickness.

Establishing the Material Foundation

While the ultimate goal may be a bilayer (BL-MoS2) or a complex heterostructure, the quality of the final device is dictated by the quality of the initial growth.

The CVD system is responsible for growing the high-quality, large-area monolayers that serve as the foundation. Without the uniformity and purity achieved by the CVD process, constructing a functional bilayer with consistent electronic properties is impossible.

Critical Control Parameters and Trade-offs

The Necessity of Parameter Tuning

CVD is not a "set it and forget it" process. The quality of the resulting MoS2 coating is highly sensitive to several variables.

Operators must strictly control substrate temperature, chamber pressure, and precursor concentration. Fluctuations in gas flow rates or the surface condition of the substrate can lead to structural defects.

Balancing Uniformity and Speed

There is often a trade-off between the deposition rate and the structural integrity of the crystal.

Proper control is essential to achieve desired properties such as thickness uniformity and correct microstructure. If the parameters are not optimized, the MoS2 may fail to achieve the aspect ratios or graphitization degrees required for high-performance applications.

Making the Right Choice for Your Goal

To maximize the effectiveness of a CVD system for MoS2 preparation, consider your specific objectives:

- If your primary focus is material quality: Prioritize the precise calibration of the two-zone furnace temperatures to ensure the molybdenum and sulfur evaporate at rates that allow for stoichiometric reaction without impurities.

- If your primary focus is structural complexity: Ensure your CVD process produces a pristine monolayer foundation first, as defects at this stage will propagate through to the bilayer or heterostructure.

Success in creating bilayer MoS2 relies on utilizing the CVD system's ability to decouple precursor control from substrate reaction conditions.

Summary Table:

| Feature | Role in BL-MoS2 Synthesis |

|---|---|

| Two-Zone Heating | Enables independent temperature control for sulfur and molybdenum evaporation. |

| Sapphire Substrate | Provides the optimal surface for uniform atomic layer deposition and growth. |

| Parameter Control | Manages chamber pressure and gas flow to ensure thickness uniformity and purity. |

| Foundation Growth | Produces high-quality monolayers required for building complex bilayers. |

Elevate Your 2D Material Research with KINTEK

Precision is the difference between a defect-free monolayer and a failed experiment. KINTEK provides industry-leading CVD systems, engineered with advanced multi-zone heating and precise pressure controls to meet the rigorous demands of MoS2 synthesis.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab requirements. Whether you are developing bilayer MoS2 or complex heterostructures, our equipment ensures the uniformity and scalability you need.

Ready to optimize your thin-film deposition? Contact our specialists today to find the perfect thermal solution for your research.

Visual Guide

References

- Louisa Scholz, Norbert Koch. Atomic-Scale Electric Potential Landscape across Molecularly Gated Bilayer MoS<sub>2</sub> Resolved by Photoemission. DOI: 10.1021/acsnano.5c10363

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- How can customers maximize the quality of CVD coatings? Master Pre-Coating Prep for Superior Results

- What environmental conditions does a quartz tube reactor provide for CNT growth? Optimize Your CVD Process Today

- What role do high-purity quartz boats play during the chemical vapor deposition (CVD) of MoS2? Optimize Thin-Film Growth

- What industries commonly use CVD processes? Unlock High-Performance Thin Films for Your Sector

- What is the function of a CVD system in Mn3O4 synthesis? Master Nucleation for Ultra-Thin Nanosheets

- What is the high-temperature capability of specialized CVD furnaces? Achieve Up to 1950°C for Advanced Materials

- Where is CVD used? Unlocking High-Performance Materials in Electronics, Energy & Aerospace