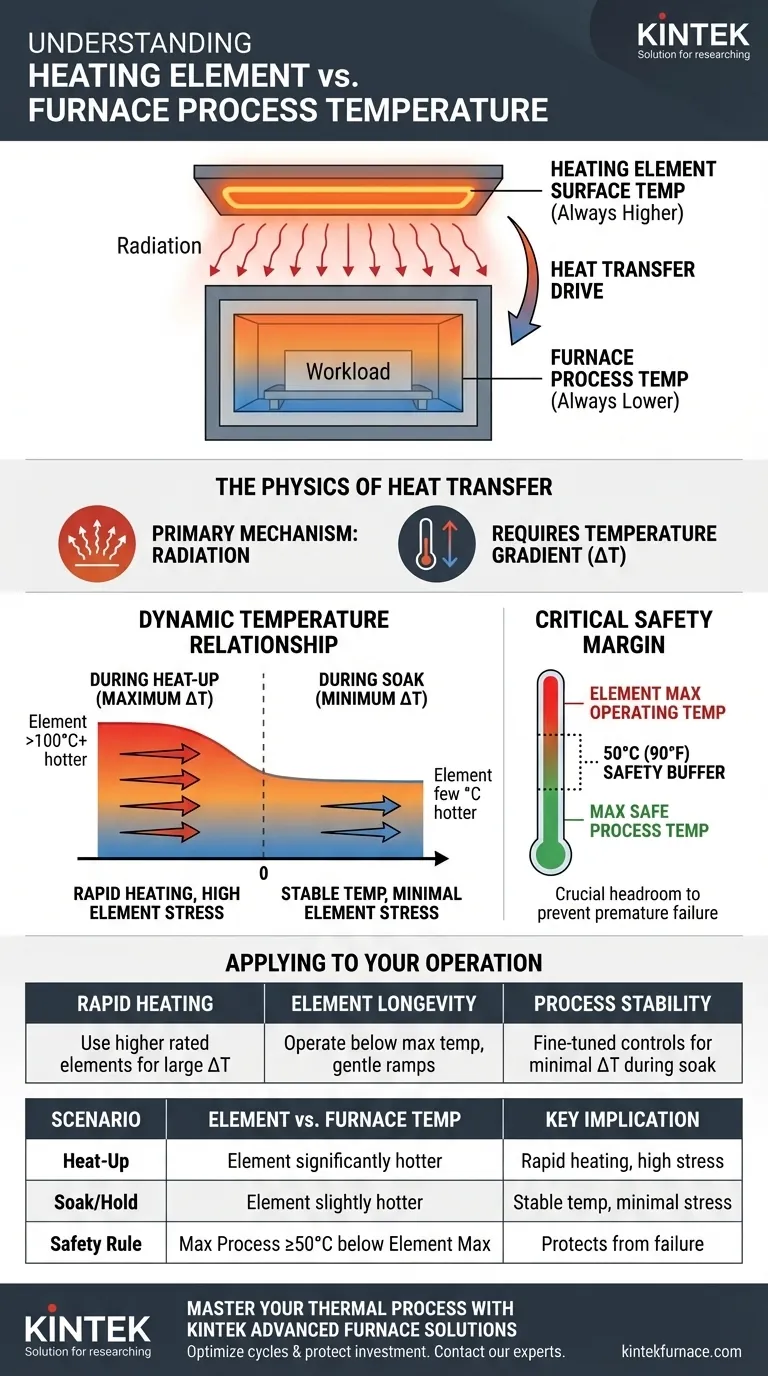

In short, the relationship is a fundamental hierarchy: The heating element's surface temperature is always higher than the furnace's internal process temperature. This temperature difference is the essential driving force that allows the element to transfer heat, primarily through radiation, to the furnace interior and the workload.

The temperature difference between the heating element and the furnace is not static; it is a dynamic variable critical to furnace performance and element longevity. Understanding and managing this gap is essential for efficient heating and preventing premature element failure.

The Physics of Heat Transfer in a Furnace

Radiation as the Primary Mechanism

Industrial heating elements work by becoming incandescent—glowing hot. This intense heat is emitted as thermal radiation, a form of electromagnetic energy that travels through the space inside the furnace.

This energy is then absorbed by the furnace walls and, most importantly, the workpiece, causing their temperature to rise.

The Necessity of a Temperature Gradient

A core principle of thermodynamics is that heat only flows from a hotter region to a colder one. For the element to transfer energy to the furnace, it must be hotter than the furnace.

The size of this temperature difference, or gradient, dictates the rate of heat transfer. A larger difference means faster heating.

Why the Temperature Gap Fluctuates

The difference between the element temperature and the furnace temperature changes dramatically depending on the stage of the heating cycle.

During Heat-Up (Maximum Difference)

When a cycle begins, the furnace and its workload are relatively cold. They act as a massive heat sink, absorbing energy very quickly.

To meet this demand and raise the furnace temperature rapidly, the elements must run significantly hotter than the furnace—often by several hundred degrees.

During Soak (Minimum Difference)

Once the furnace reaches its target setpoint (the "soak" period), the workload is saturated with heat. The only energy needed is the amount required to offset heat loss through the furnace insulation.

In this phase, the elements only need to be slightly hotter than the furnace atmosphere to maintain a stable temperature. The difference might shrink to just a few degrees.

Understanding the Critical Safety Margin

While a large temperature gap is useful for rapid heating, it pushes the element closer to its operational limits, creating a critical trade-off between speed and lifespan.

The Element's Maximum Operating Temperature

Every heating element material has a maximum recommended temperature. Exceeding this limit, even for short periods, causes accelerated degradation, oxidation, and ultimately, premature failure.

Why You Can't Run at the Limit

Attempting to run a furnace process at a temperature very close to the element's maximum rating leaves no room for the temperature "overshoot" needed during the heat-up phase.

This would force the element to operate constantly at its failure point, drastically shortening its service life.

The 50°C (90°F) Rule of Thumb

To ensure a reliable service life, a safety buffer is essential. The maximum furnace process temperature is generally limited to at least 50°C (90°F) below the element material's maximum safe operating temperature.

This margin provides the necessary headroom for the element to get significantly hotter than the furnace during heat-up without destroying itself.

Applying This to Your Furnace Operation

Balancing heating speed, process stability, and equipment longevity depends entirely on how you manage this temperature relationship.

- If your primary focus is rapid heating: You must use elements rated for temperatures significantly higher than your process temperature to safely create the large difference needed for fast heat-up cycles.

- If your primary focus is element longevity: Operate your furnace at a temperature well below the element's maximum limit and consider using less aggressive ramp rates to minimize thermal stress.

- If your primary focus is process stability: During the soak period, a well-tuned temperature controller is critical to maintaining the minimal, stable temperature difference required for consistent part quality.

Ultimately, viewing the heating element not just as a simple heat source but as a component operating within a dynamic thermal system is the key to mastering your process.

Summary Table:

| Scenario | Element Temp vs. Furnace Temp | Key Implication |

|---|---|---|

| During Heat-Up | Element is significantly hotter (e.g., 100s of °C) | Enables rapid heating; high stress on elements |

| During Soak/Hold | Element is slightly hotter (e.g., a few °C) | Maintains stable temperature with minimal stress |

| Critical Safety Rule | Max Process Temp should be ≥50°C below Element Max Temp | Protects element from premature failure |

Master Your Thermal Process with KINTEK's Advanced Furnace Solutions

Understanding the delicate balance between element and process temperature is crucial for achieving consistent results and maximizing equipment lifespan. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your specific needs.

Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is engineered for precise temperature control and reliability. Coupled with our strong deep customization capability, we can design a system that perfectly manages the critical temperature relationship for your unique experimental or production requirements.

Optimize your heating cycles and protect your investment. Contact our experts today to discuss how a KINTEK furnace can enhance your process efficiency and longevity.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C