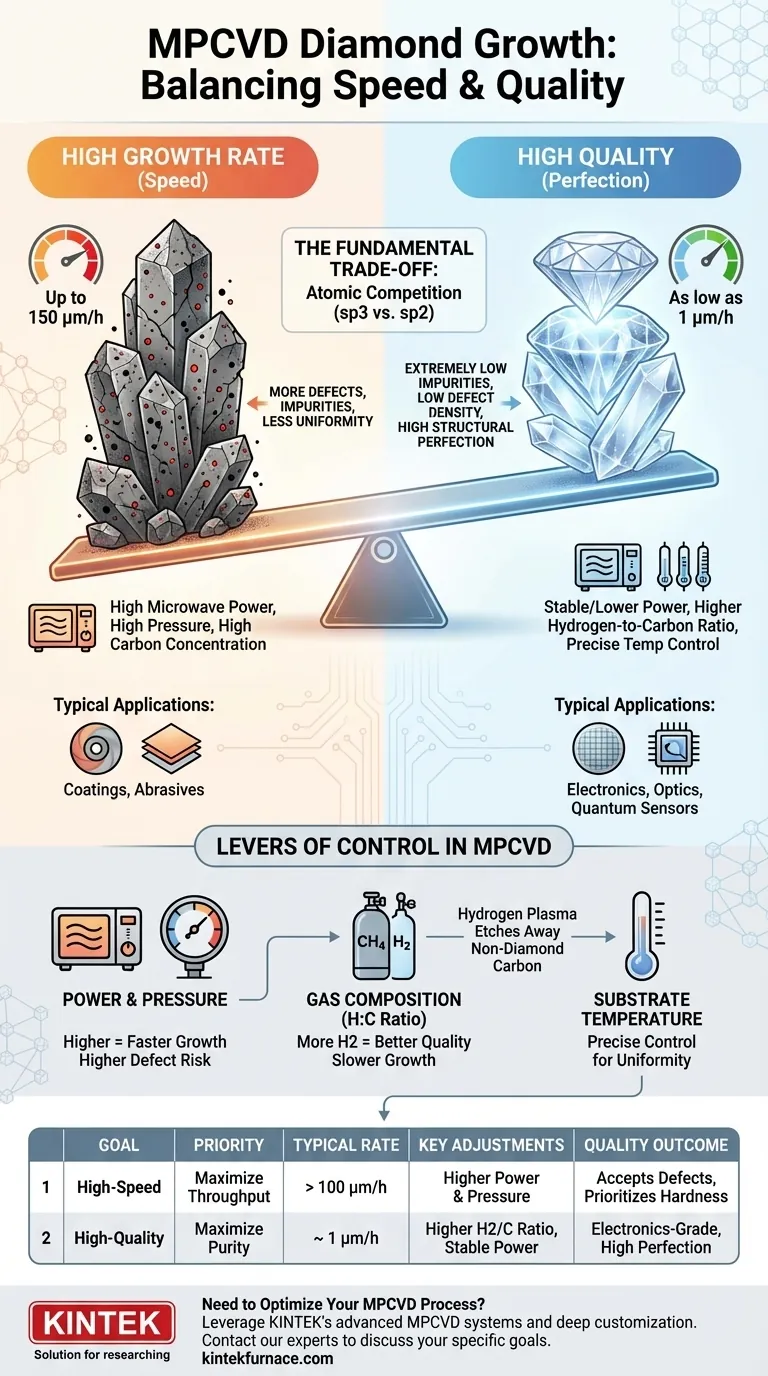

In short, the relationship between diamond growth rate and quality in the Microwave Plasma Chemical Vapor Deposition (MPCVD) method is an inverse one. Increasing the growth rate almost always comes at the expense of diamond quality, leading to more defects, impurities, and less structural uniformity. Achieving high-quality, electronics-grade diamond requires a slower, more precisely controlled process.

The core challenge of MPCVD diamond synthesis lies in managing a fundamental trade-off: the very conditions that accelerate growth—high energy and high concentrations of reactive gases—also create an environment where defects and non-diamond carbon forms are more likely to be incorporated into the crystal lattice.

Why Faster Growth Often Means Lower Quality

To understand this trade-off, we must look at what happens at the atomic level. Diamond growth is a competition between the desired sp3-bonded carbon (diamond) and the undesired sp2-bonded carbon (graphite or amorphous carbon).

The Role of Plasma Density and Energy

In MPCVD, microwave energy is used to excite a gas mixture (typically methane in hydrogen) into a plasma. Increasing the microwave power and chamber pressure makes this plasma denser and more reactive.

This highly active environment accelerates the decomposition of the source gas, which increases the concentration of carbon-containing groups available for deposition. This directly boosts the growth rate.

However, this high-energy state is a double-edged sword. It can lead to the formation of defects and incorporate unwanted sp2 carbon, which degrades the overall quality of the diamond crystal.

The Problem of Inhomogeneity

Extremely high growth rates, sometimes reaching up to 150 μm/h, are often localized. This rapid deposition can result in diamonds with limited growth areas and poor homogeneity across the substrate, making them unsuitable for applications requiring large, uniform films.

The Levers of Control in MPCVD

While the trade-off is fundamental, operators have several parameters they can adjust to find a balance between growth rate and quality for a specific application.

Microwave Power and Chamber Pressure

As mentioned, increasing power and pressure directly increases the growth rate. This is done by enhancing the ionization of the reaction gas, creating a higher density of the atomic groups responsible for building the diamond. The trade-off is a higher risk of defects.

Gas Composition: The Hydrogen-Carbon Balance

The ratio of hydrogen to carbon in the gas mixture is critical. Carbon-containing groups (like CH3) are the building blocks for the diamond.

Crucially, hydrogen plasma preferentially etches away sp2 carbon much faster than it etches sp3 diamond. A higher concentration of atomic hydrogen acts as a quality control mechanism, cleaning the surface of non-diamond carbon during growth. This is why a precise balance is essential for achieving high quality.

Substrate Temperature

The temperature of the substrate where the diamond grows is another key variable. It influences which chemical reactions are favored on the growth surface. Precise temperature control is essential for ensuring uniform film thickness and high quality.

Understanding the Trade-offs: Speed vs. Perfection

The "best" process depends entirely on the end goal. There is no single set of parameters that is optimal for every application.

The High-Speed Scenario: Coatings and Abrasives

For applications like protective coatings or industrial abrasives, a very high growth rate might be the primary objective. A polycrystalline diamond film grown at over 100 μm/h may have defects, but its extreme hardness is still the dominant and most valuable property.

In this case, one would favor higher microwave power and pressure, accepting the resulting decrease in crystal purity and uniformity.

The High-Quality Scenario: Electronics and Optics

For high-precision applications like semiconductors, quantum sensors, or high-power optics, quality is non-negotiable. These fields demand diamond with extremely low impurity content and defect density.

Achieving this requires a slower, more deliberate process. This involves using high-purity source gases, a reliable high-vacuum system to prevent contamination, and carefully optimized power and gas flow settings that prioritize quality over speed. The growth rate may be as low as 1 μm/h in these exacting processes.

Making the Right Choice for Your Goal

Ultimately, navigating the relationship between growth rate and quality is about defining your primary objective.

- If your primary focus is maximizing throughput for industrial applications: Prioritize higher microwave power, chamber pressure, and carbon concentration, accepting the trade-off in crystal purity and uniformity.

- If your primary focus is achieving gem or electronic-grade quality: Prioritize high-purity source gases, a higher hydrogen-to-carbon ratio, and stable, often lower, power settings to ensure slow, controlled, and defect-free growth.

Balancing these factors is the key to successfully harnessing the power of the MPCVD method for your specific purpose.

Summary Table:

| Goal | Priority | Typical Growth Rate | Key Parameter Adjustments | Quality Outcome |

|---|---|---|---|---|

| High-Speed (Coatings/Abrasives) | Maximize Throughput | > 100 μm/h | Higher Microwave Power, Pressure, Carbon Concentration | Accepts defects; prioritizes hardness & deposition speed |

| High-Quality (Electronics/Optics) | Maximize Purity & Uniformity | ~1 μm/h | High-Purity Gases, Higher H2/C Ratio, Stable/Lower Power | Electronics-grade; low defects, high structural perfection |

Need to Optimize Your MPCVD Process for Specific Diamond Quality or Growth Rate Goals?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our MPCVD systems, backed by strong deep customization capabilities, are designed to help you precisely balance growth rate and diamond quality—whether for high-speed industrial coatings or ultra-pure electronic-grade applications.

Contact our experts today to discuss how our tailored MPCVD solutions can meet your unique research and production requirements.

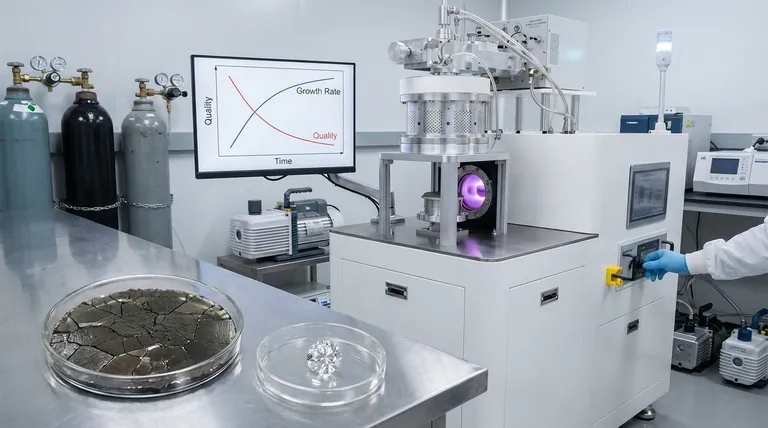

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are some applications of MPCVD? Unlock High-Purity Diamond for Advanced Engineering

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision