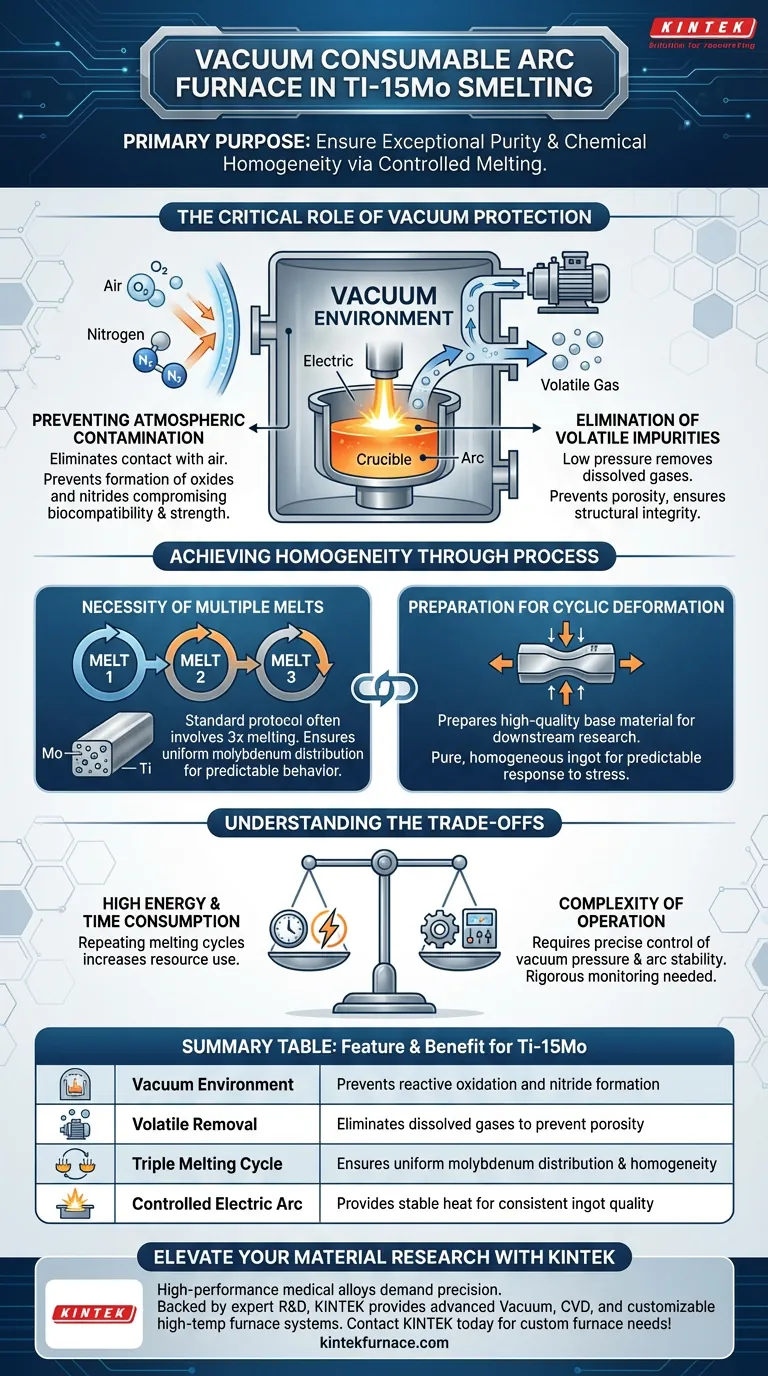

The primary purpose of using a Vacuum Consumable Arc Furnace in the production of Ti-15Mo medical alloys is to ensure exceptional purity and chemical homogeneity through a controlled melting process. By utilizing an electric arc within a vacuum, this equipment prevents the titanium from reacting with the atmosphere while actively removing volatile impurities, establishing a high-quality foundation for medical applications.

Medical-grade alloys require strict adherence to safety and performance standards. The Vacuum Consumable Arc Furnace addresses this by isolating the melt from atmospheric contamination and employing repeated melting cycles to guarantee a chemically uniform, defect-free material.

The Critical Role of Vacuum Protection

Preventing Atmospheric Contamination

Titanium and its alloys are highly reactive elements, particularly at the elevated temperatures required for smelting. Without protection, titanium can undergo violent reactions with oxygen and nitrogen in the air.

The Vacuum Consumable Arc Furnace operates in a strict vacuum environment. This eliminates contact with air, preventing the formation of oxides and nitrides that would otherwise compromise the alloy's biocompatibility and mechanical strength.

Elimination of Volatile Impurities

Beyond simply shielding the metal, the vacuum plays an active purification role. The low-pressure environment facilitates the removal of volatile impurity gases.

Under these conditions, dissolved gases are drawn out of the molten metal. This reduction in dissolved gas content is essential for preventing porosity and ensuring the structural integrity of the final ingot.

Achieving Homogeneity Through Process

The Necessity of Multiple Melts

A single melt is rarely sufficient to achieve the strict uniformity required for medical devices. The standard protocol for Ti-15Mo often involves repeating the melting process, typically three times.

This repetition ensures that the molybdenum is evenly distributed throughout the titanium matrix. High chemical uniformity is non-negotiable, as inconsistent composition can lead to unpredictable mechanical behavior in the human body.

Preparation for Cyclic Deformation

The ultimate goal of this smelting process is to produce a high-quality base material suitable for downstream processing. The primary reference highlights that this specific furnace prepares the alloy for subsequent cyclic deformation research.

By starting with a pure, homogeneous ingot, researchers and manufacturers ensure that the material responds predictably to physical stress and shaping.

Understanding the Trade-offs

High Energy and Time Consumption

While the Vacuum Consumable Arc Furnace yields superior results, it is a resource-intensive process. Repeating the melting cycle three times significantly increases energy consumption and processing time compared to single-melt methods.

Complexity of Operation

The equipment requires precise control over the vacuum pressure and the electric arc stability. Any fluctuation in the vacuum level can reintroduce contamination, meaning the process demands rigorous monitoring and maintenance of the vacuum seals and pumps.

Making the Right Choice for Your Goal

To maximize the quality of your Ti-15Mo alloy, align your processing steps with your specific material requirements:

- If your primary focus is Biocompatibility: Prioritize the vacuum integrity to ensure the complete removal of volatile gases and prevention of oxide inclusions.

- If your primary focus is Mechanical Consistency: Adhere strictly to the triple-melting protocol to guarantee the chemical uniformity required for predictable deformation.

The Vacuum Consumable Arc Furnace is not merely a melting tool; it is a purification system that transforms raw elements into a safe, reliable medical-grade material.

Summary Table:

| Feature | Benefit for Ti-15Mo Alloys |

|---|---|

| Vacuum Environment | Prevents reactive oxidation and nitride formation |

| Volatile Removal | Eliminates dissolved gases to prevent material porosity |

| Triple Melting Cycle | Ensures uniform molybdenum distribution and homogeneity |

| Controlled Electric Arc | Provides stable heat for consistent ingot quality |

Elevate Your Material Research with KINTEK

High-performance medical alloys like Ti-15Mo demand uncompromising precision. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Vacuum, CVD, and customizable high-temp furnace systems specifically designed to meet the rigorous standards of lab and industrial production. Whether you need a standard Muffle furnace or a specialized Vacuum system, our equipment ensures the chemical uniformity and purity your unique projects require.

Ready to optimize your smelting process? Contact KINTEK today to discuss your custom furnace needs!

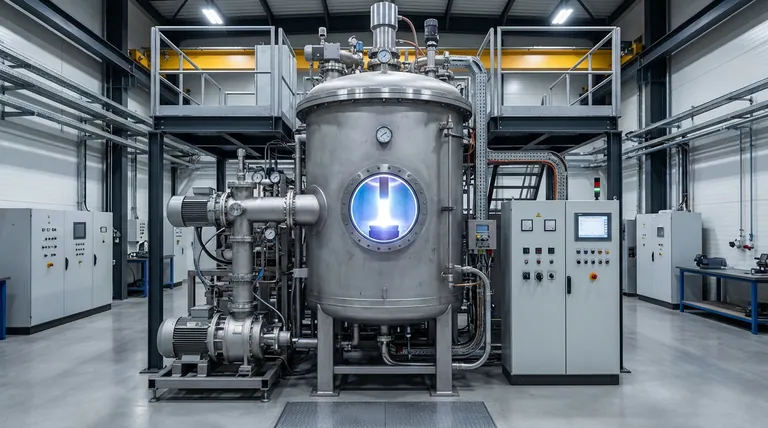

Visual Guide

References

- Tiewei Xu, Bin-Jiang Lv. The {332}<113> Twinning Behavior of a Ti-15Mo Medical Alloy during Cyclic Deformation and Its Effect on Microstructure and Performance. DOI: 10.3390/ma17071462

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What technical challenges are associated with vacuum or protective atmosphere induction furnaces? Overcome Them for Superior Material Purity

- How does electromagnetic stirring in IGBT induction melting furnaces improve melt quality? Achieve Superior Metal Purity and Homogeneity

- What advantages does an electron beam melting furnace offer? Superior Purification for Zirconium Refining

- Why is a vacuum environment necessary for PBF-EB? Ensure Beam Precision & Material Purity

- Why is the hydraulic vacuum dispersion method suitable for high-melting-point metals like cast iron and steel?

- What makes VIM furnaces energy efficient compared to traditional melting methods? Discover Direct Heating & Vacuum Benefits

- How are induction melting furnaces utilized in the jewelry and precious metal industry? Achieve Purity & Efficiency

- What is the purpose of using a vacuum induction furnace in this application? Achieve Superior Purity and Control