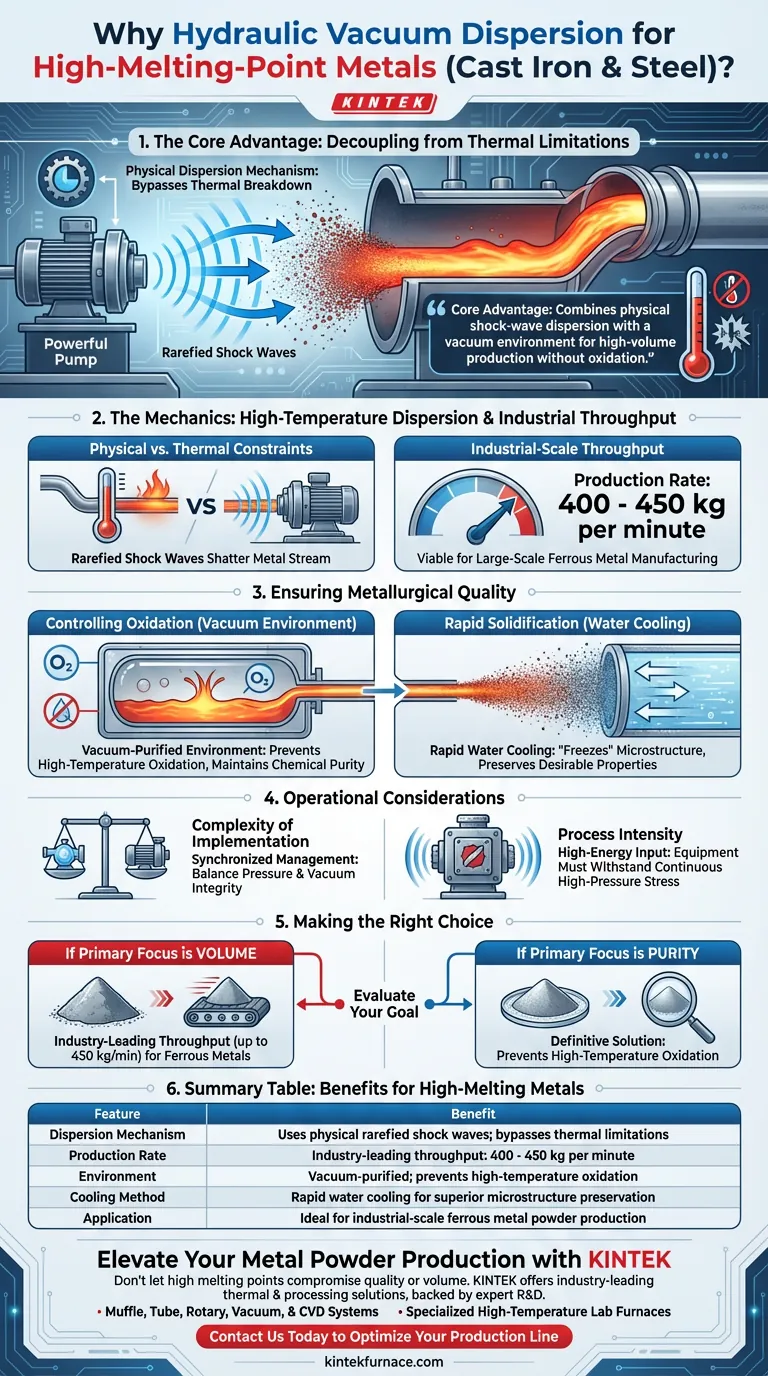

The hydraulic vacuum dispersion method is uniquely suited for processing high-melting-point metals, such as cast iron and steel, because it decouples the dispersion mechanism from thermal limitations. Instead of relying on thermal breakdown, the system utilizes physical rarefied shock waves generated by high-pressure water pumps to disintegrate the molten metal. This allows the process to maintain efficiency regardless of how high the material's melting temperature is.

The core advantage of this method lies in its ability to combine physical shock-wave dispersion with a vacuum environment, enabling high-volume production rates while strictly preventing the oxidation common in high-temperature processing.

The Mechanics of High-Temperature Dispersion

Physical vs. Thermal Constraints

Processing metals with high melting points often strains traditional atomization methods.

The hydraulic vacuum dispersion method bypasses this by using a physical dispersion mechanism.

High-pressure water pumps generate rarefied shock waves that physically shatter the metal stream, ensuring the high melting point of steel or cast iron does not hinder the process.

Industrial-Scale Throughput

Because the physical force of the shock waves is the primary driver, production speeds are exceptionally high.

For ferrous metals like cast iron and steel, this system can achieve production rates between 400 and 450 kg per minute.

This makes it a viable solution for large-scale industrial manufacturing requirements.

Ensuring Metallurgical Quality

Controlling Oxidation

High temperatures usually increase the risk of rapid oxidation, which degrades metal powder quality.

To counter this, the process operates within a vacuum-purified environment.

This isolation from oxygen ensures the chemical purity of the metal is maintained, even when processed in a molten state.

Rapid Solidification

The method employs extremely rapid water cooling immediately following dispersion.

This sudden drop in temperature "freezes" the microstructure of the metal powders.

Combined with the vacuum environment, this preserves the desirable properties of the ferrous metals without introducing impurities.

Operational Considerations

Complexity of Implementation

While effective, this method requires synchronized management of high-pressure hydraulics and vacuum systems.

Operators must maintain a delicate balance between the water pump pressure and the vacuum integrity to ensure consistent shock wave generation.

Process Intensity

The reliance on physical shock waves implies a high-energy input system.

The equipment must be robust enough to withstand the continuous stress of generating high-pressure waves required to disperse dense, high-melting-point materials.

Making the Right Choice for Your Goal

When evaluating the hydraulic vacuum dispersion method for your production line, consider your primary constraints:

- If your primary focus is volume: This method provides industry-leading throughput for ferrous metals, capable of processing up to 450 kg per minute.

- If your primary focus is purity: The vacuum environment offers a definitive solution for preventing high-temperature oxidation in cast iron and steel powders.

This method effectively bridges the gap between high-volume output and high-quality material preservation for the most demanding ferrous metals.

Summary Table:

| Feature | Benefit for High-Melting Metals |

|---|---|

| Dispersion Mechanism | Uses physical rarefied shock waves; bypasses thermal limitations |

| Production Rate | Industry-leading throughput: 400 - 450 kg per minute |

| Environment | Vacuum-purified; prevents high-temperature oxidation |

| Cooling Method | Rapid water cooling for superior microstructure preservation |

| Application | Ideal for industrial-scale ferrous metal powder production |

Elevate Your Metal Powder Production with KINTEK

Don't let high melting points compromise your output quality or volume. KINTEK provides industry-leading thermal and processing solutions designed for the most demanding materials. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature lab furnaces—all fully customizable to your unique industrial needs.

Whether you are processing cast iron, steel, or advanced alloys, our systems ensure maximum purity and efficiency. Contact us today to optimize your production line!

Visual Guide

References

- David Sakhvadze, Besik Saralidze. Technological line for production of activated powders by hydro-vacuum dispersion of liquid metals. DOI: 10.51582/interconf.19-20.01.2024.060

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do induction furnaces generate heat for smelting precious metals? Discover Fast, Pure Melting Solutions

- Why are graphene induction coils able to maintain more stable heating rates? Achieve Precision at 2000°C+

- What are the advantages of using an induction-heated vacuum furnace? Achieve Purity and Precision in Material Processing

- In which industries is the IGBT induction melting machine commonly used? Key Applications & Benefits

- What are some common applications of medium frequency induction furnaces? Unlock Precision Heating for Your Operations

- Why is a cooling system necessary in an induction heater? Prevent Overheating and Ensure Safe Operation

- What is a Vacuum Induction Melting Furnace (VIM) and what processes does it perform? Achieve Ultimate Metal Purity and Precision

- What auxiliary role does a Ni/Al2O3 catalyst play in induction heating? Enhancing Ammonia Decomposition Uniformity