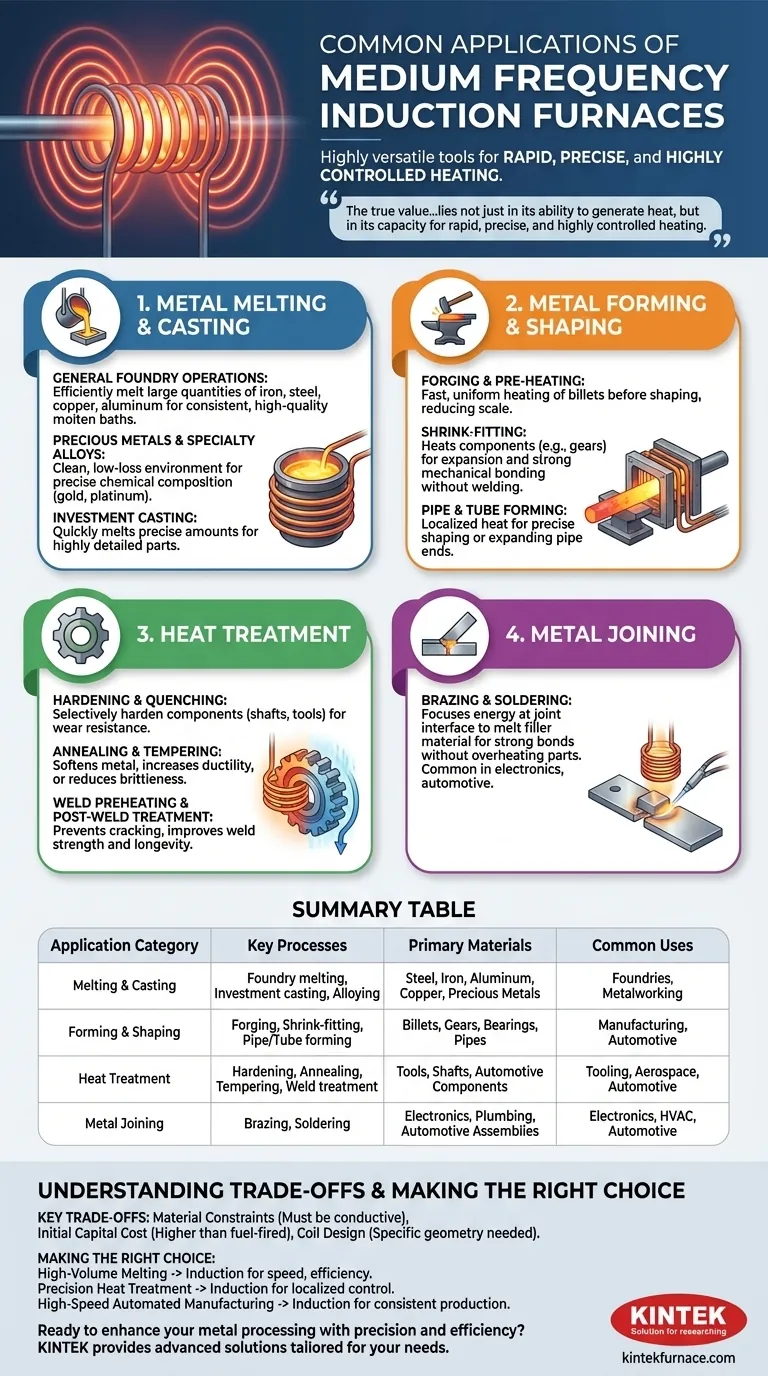

At their core, medium frequency induction furnaces are highly versatile tools used for a wide range of industrial processes. Their most common applications fall into four main categories: melting and casting metals like steel and aluminum, shaping metal through forging, altering metal properties via heat treatment, and joining components together through brazing or soldering.

The true value of a medium frequency induction furnace lies not just in its ability to generate heat, but in its capacity for rapid, precise, and highly controlled heating. This precision is why it excels in such a diverse set of applications, from melting tons of raw material to performing delicate heat treatments on small, critical parts.

Core Applications in Metal Melting and Casting

One of the most widespread uses for medium frequency induction furnaces is in foundries and metalworking facilities for melting raw materials. The electromagnetic induction process ensures the material melts uniformly from within.

General Foundry Operations

Induction furnaces are the workhorses for melting large quantities of iron, steel, copper, and aluminum. Their efficiency and precise temperature control result in a consistent, high-quality molten metal bath, which is critical for producing reliable castings.

Precious Metals and Specialty Alloys

For materials like gold, platinum, and complex alloys, precision is paramount. Induction furnaces provide a clean melting environment with minimal material loss, ensuring the chemical composition of the final alloy remains exact.

Investment Casting

Investment casting is a process that creates highly detailed and complex parts. Induction furnaces are ideal for this application because they can quickly melt the precise amount of metal needed while maintaining the strict temperature required for the mold.

Applications in Metal Forming and Shaping

Before metal can be reshaped, it must be heated to a malleable state. Induction heating provides the speed and consistency required for modern forming operations.

Forging and Pre-heating

Induction is widely used to heat metal billets before they are forged or pressed into shape. The heating is extremely fast and uniform, which increases throughput and reduces the formation of scale on the part's surface.

Shrink-Fitting

This process involves heating a component, such as a gear or bearing collar, causing it to expand. It is then placed over another part, and as it cools, it shrinks to create an exceptionally strong mechanical bond without welding.

Pipe and Tube Forming

For applications like expanding the end of a steel pipe, induction allows heat to be applied to a very specific, localized area. This enables precise shaping without affecting the integrity of the rest of the pipe.

Applications in Heat Treatment

Heat treatment modifies the internal crystalline structure of a metal to change its physical properties. The precise control of induction heating makes it perfect for these sensitive processes.

Hardening and Quenching

Components like shafts, gears, and tools can be selectively hardened using induction. A specific area is rapidly heated and then quickly cooled (quenched), creating a very hard, wear-resistant surface while leaving the core of the component tough and ductile.

Annealing and Tempering

Annealing is a process that softens metal and increases its ductility. Tempering reduces brittleness after hardening. Induction allows for precise, repeatable heating cycles to achieve these exact metallurgical properties.

Weld Preheating and Post-Weld Treatment

Applying heat before and after welding can prevent cracking and relieve internal stresses, dramatically improving the strength and longevity of the weld. Induction provides a portable and controllable method for this critical task.

Applications in Metal Joining

Induction is also a highly effective method for joining metal parts together, prized for its speed and cleanliness.

Brazing and Soldering

In brazing, two metal pieces are joined by a filler material with a lower melting point. Induction heating focuses energy only at the joint interface, melting the filler material to create a strong bond without overheating or warping the parent components. This is common in electronics, plumbing, and automotive manufacturing.

Understanding the Key Trade-offs

While incredibly versatile, medium frequency induction furnaces are not the universal solution for every heating task. Understanding their limitations is key to proper application.

Material Constraints

The fundamental principle of induction heating requires the workpiece to be electrically conductive. It is ineffective for heating non-conductive materials like most ceramics or plastics directly.

Initial Capital Cost

Induction heating systems often have a higher initial purchase price compared to conventional fuel-fired furnaces. This cost is typically justified by higher efficiency, greater process control, and lower operational expenses over time.

Coil Design and Geometry

The induction coil must be designed to match the geometry of the part being heated for maximum efficiency. While this allows for incredible precision, it means a "one-size-fits-all" approach is often impractical for facilities with highly varied part shapes.

Making the Right Choice for Your Goal

Selecting the right heating technology depends entirely on your primary objective.

- If your primary focus is high-volume melting and casting: Induction offers unmatched speed, energy efficiency, and melt purity for producing high-quality raw materials.

- If your primary focus is precision heat treatment: The localized, controllable, and repeatable nature of induction heating is ideal for altering the specific properties of finished parts.

- If your primary focus is high-speed, automated manufacturing: Integrating induction for tasks like forging, brazing, or shrink-fitting enables fast, clean, and consistent production lines.

Understanding these distinct applications empowers you to leverage induction technology for its greatest strategic advantage.

Summary Table:

| Application Category | Key Processes | Primary Materials |

|---|---|---|

| Melting & Casting | Foundry melting, Investment casting, Alloying | Steel, Iron, Aluminum, Copper, Precious Metals |

| Forming & Shaping | Forging, Shrink-fitting, Pipe/Tube forming | Billets, Gears, Bearings, Pipes |

| Heat Treatment | Hardening, Annealing, Tempering, Weld treatment | Tools, Shafts, Automotive Components |

| Metal Joining | Brazing, Soldering | Electronics, Plumbing, Automotive Assemblies |

Ready to enhance your metal processing with precision and efficiency? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced medium frequency induction furnace solutions tailored for foundries, metalworking facilities, and high-volume manufacturers. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique operational requirements—whether for high-volume melting, precision heat treatment, or automated manufacturing. Contact us today to discuss how our solutions can optimize your processes and deliver superior results. Get in touch with our experts for a customized consultation!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries