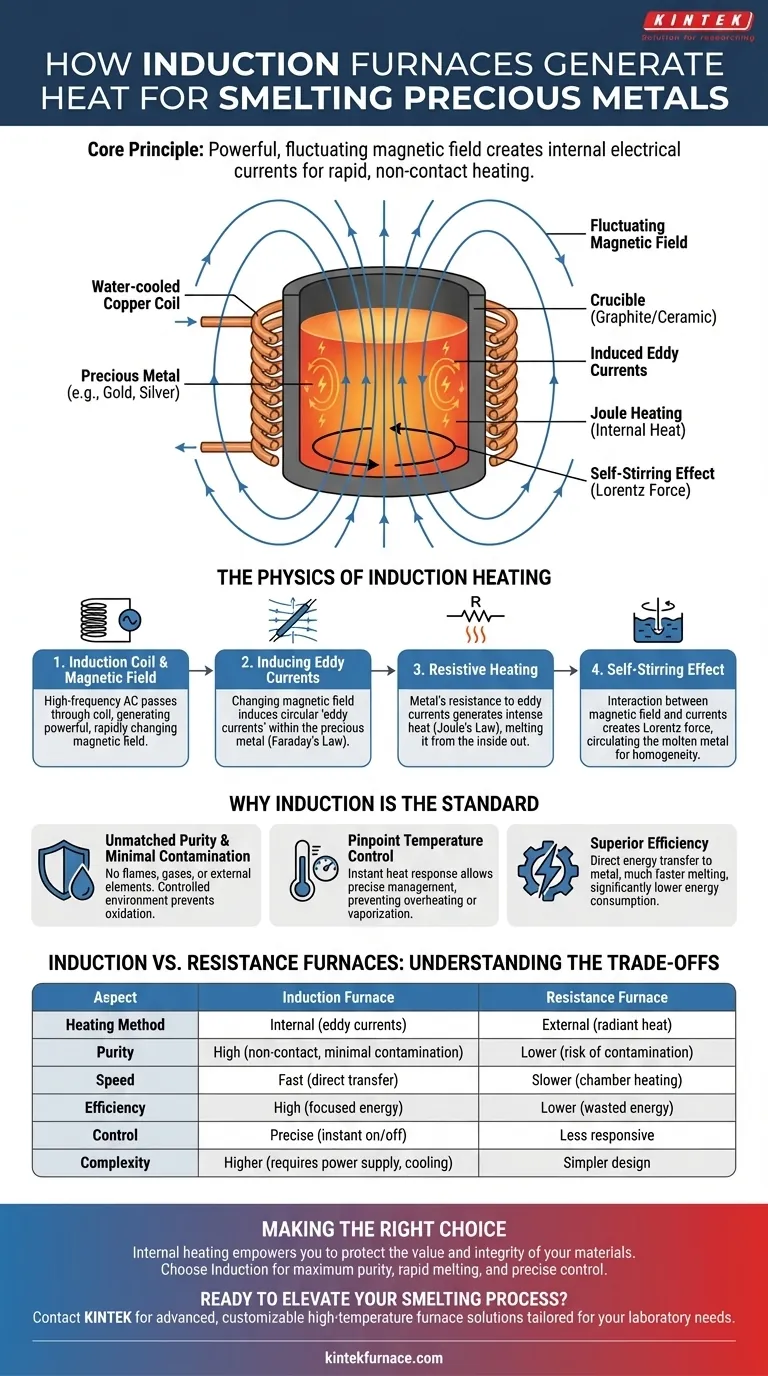

At its core, an induction furnace generates heat by using a powerful, fluctuating magnetic field. This field creates electrical currents directly within the precious metal itself. The metal’s natural resistance to these currents causes it to heat up rapidly from the inside out, turning the material into its own heating element.

The critical distinction of induction heating is that it is a non-contact process that generates heat inside the target material. This is fundamentally different from traditional furnaces that heat a chamber from the outside, offering unparalleled speed, purity, and control for high-value metals.

The Physics of Induction Heating

To understand why induction is the preferred method for smelting precious metals, we must first look at the principles that make it work. The process is a direct application of electromagnetic laws.

The Induction Coil and Magnetic Field

The furnace is built around a water-cooled copper coil. When a high-frequency alternating current (AC) is passed through this coil, it generates a powerful and rapidly changing magnetic field in the space at its center, where the crucible holding the metal is placed.

Inducing Eddy Currents

According to Faraday's Law of Induction, a changing magnetic field will induce an electrical current in any conductor placed within it. This effect creates circular electrical currents, known as eddy currents, that flow within the precious metal.

Resistive Heating (Joule's Law)

All metals, including gold, silver, and platinum, have a degree of electrical resistance. As the powerful eddy currents flow through the metal, they encounter this resistance, which generates intense heat (a phenomenon called Joule heating). This internal heating is what causes the metal to melt efficiently.

The Self-Stirring Effect

A unique benefit of this process is the natural stirring action it creates. The interaction between the magnetic field and the eddy currents produces a force (the Lorentz force) that causes the molten metal to circulate. This self-stirring ensures a homogenous mixture, which is critical when creating precise alloys.

Why Induction is the Standard for Precious Metals

The unique physics of induction heating provides specific advantages that are essential when working with valuable and sensitive materials.

Unmatched Purity and Minimal Contamination

Because there are no flames, combustion gases, or external heating elements, the risk of contaminating the precious metal is virtually eliminated. The process is clean, and the controlled environment inside the crucible—often made of non-reactive graphite or ceramic—prevents oxidation and preserves the metal's purity.

Pinpoint Temperature Control

Heat is generated almost instantly the moment the coil is energized and stops as soon as power is cut. This allows for extremely precise and responsive temperature control, preventing overheating that could vaporize valuable metal or damage alloys.

Superior Efficiency

In a traditional furnace, a great deal of energy is wasted heating the furnace walls and the air around the crucible. In an induction furnace, nearly all the energy is transferred directly into the metal. This results in much faster melting times and significantly lower energy consumption.

Understanding the Trade-offs: Induction vs. Resistance Furnaces

To fully appreciate induction's role, it is useful to compare it to a common alternative: the resistance furnace.

Heating Method: Internal vs. External

This is the fundamental difference. An induction furnace uses internal heating. A resistance furnace uses external heating, where an element (like a coiled wire) heats up and radiates that heat inward to melt the material.

Speed and Purity

Induction is significantly faster because it doesn't need to heat a large chamber first. Its non-contact method also offers higher purity, whereas a degrading resistance element could potentially introduce contaminants.

Equipment Complexity

Induction systems are more complex, requiring a high-frequency power supply and water-cooling systems for the coil. Resistance furnaces are generally simpler in design and can have a lower initial equipment cost, but they operate with lower efficiency and less control.

Making the Right Choice for Your Smelting Goal

Your choice of technology should be guided by your end goal and the value of the materials you are processing.

- If your primary focus is maximum purity and rapid melting: Induction is the definitive choice due to its direct, contaminant-free heating mechanism.

- If your primary focus is process control and alloy consistency: The precise temperature management and self-stirring effect of induction are indispensable for producing high-quality, homogenous alloys.

- If your primary focus is minimizing initial investment for less-sensitive materials: A simpler resistance furnace may be considered, but you must accept the inherent compromises in speed, efficiency, and potential purity.

Ultimately, understanding this core principle of internal heating empowers you to select the precise tool that protects the value and integrity of your materials.

Summary Table:

| Aspect | Induction Furnace | Resistance Furnace |

|---|---|---|

| Heating Method | Internal (eddy currents) | External (radiant heat) |

| Purity | High (non-contact, minimal contamination) | Lower (risk of contamination) |

| Speed | Fast (direct energy transfer) | Slower (chamber heating required) |

| Efficiency | High (energy focused on metal) | Lower (energy wasted on surroundings) |

| Control | Precise (instant on/off) | Less responsive |

| Complexity | Higher (requires power supply, cooling) | Simpler design |

Ready to elevate your smelting process with advanced induction technology? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for laboratories working with precious metals. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Experience unparalleled purity, efficiency, and control—contact us today to discuss how we can optimize your operations and protect the value of your materials!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys