In the jewelry and precious metal industry, induction melting furnaces are the primary technology used to melt gold, silver, platinum, and their associated alloys. Their core function is to transform solid metals into a liquid state with exceptional speed and precision, a critical requirement for casting high-quality jewelry components, refining scrap, and creating precise metal alloys.

The fundamental advantage of induction melting is not just its speed, but its inherent cleanliness and control. By heating the metal from within using an electromagnetic field, it avoids the contamination and material loss common with traditional flame-based methods, directly preserving the value and integrity of precious materials.

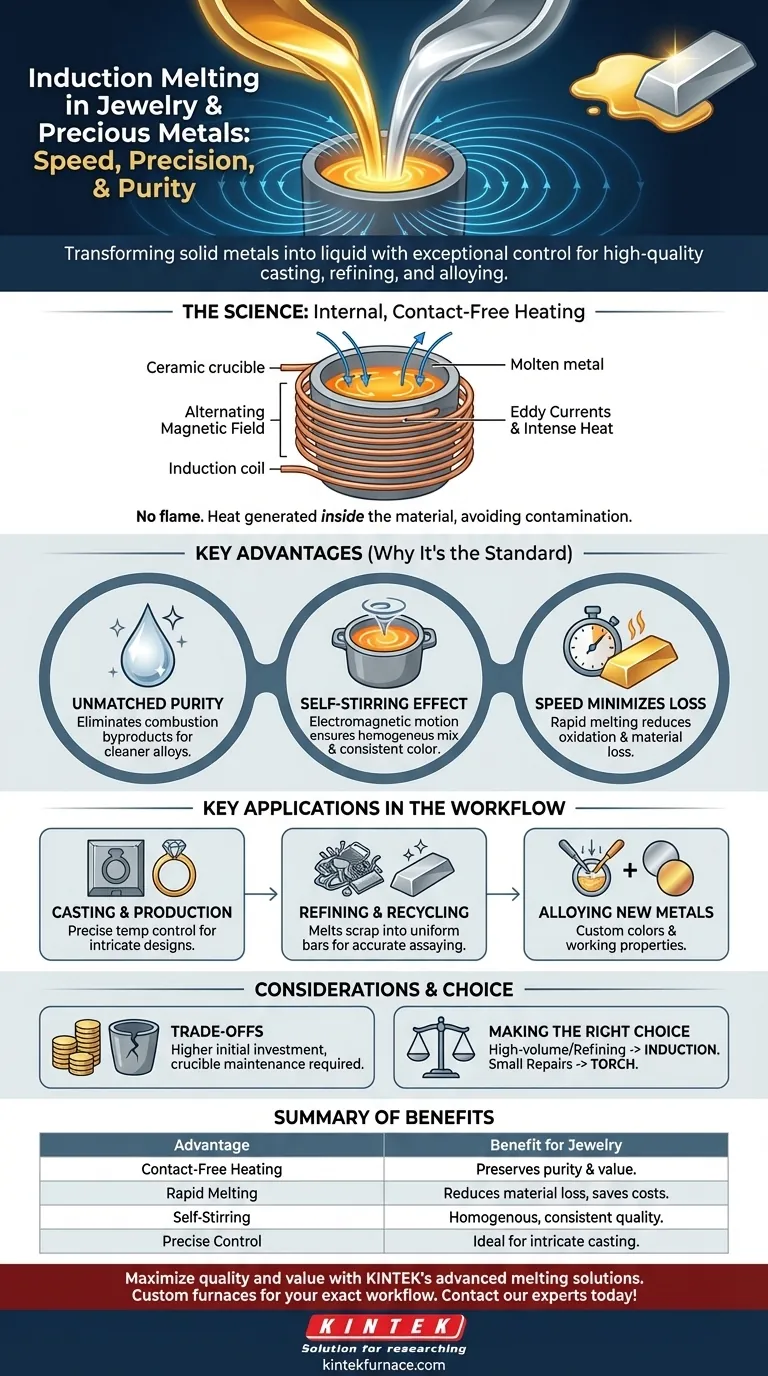

Why Induction Is the Standard for Precious Metals

The dominance of induction technology in this field stems from its underlying scientific principles, which translate directly into tangible benefits for working with high-value metals.

The Principle: Internal, Contact-Free Heating

An induction furnace uses a powerful, alternating magnetic field to induce electrical currents (known as eddy currents) directly within the metal. The metal's natural resistance to these currents generates intense, rapid heat.

Crucially, this means there is no external flame or heating element touching the metal. The heat is generated inside the material itself.

Unmatched Purity and Quality Control

Because the heating process is contact-free, it eliminates the risk of contamination from combustion byproducts like gas or carbon, which can compromise the purity and color of an alloy.

This level of purity is essential for meeting legal standards for karat gold and ensuring the final product has the desired metallurgical properties.

The Self-Stirring Effect

The magnetic field that heats the metal also creates a natural stirring motion within the molten liquid. This electromagnetic stirring is vital for creating perfectly homogenous alloys.

When making 14k gold, for example, the furnace automatically and thoroughly mixes the pure gold with the copper, silver, and other elements, ensuring a consistent color and quality throughout the entire batch.

Speed Minimizes Metal Loss

Induction furnaces can melt a crucible of gold in a matter of minutes. This incredible speed is not just for efficiency; it minimizes the time the molten metal is exposed to air.

Less time in a molten state means less opportunity for oxidation, which is a primary cause of material loss. For precious metals, even a small percentage of loss can represent a significant financial cost.

Key Applications in the Jewelry Workflow

Induction furnaces are not a single-use tool; they are integrated into several critical stages of the precious metal lifecycle.

Casting and Production

This is the most common application. An operator melts a precise amount of metal or alloy to a specific temperature, then pours it into molds, typically for lost-wax casting. The precise temperature control ensures the metal flows correctly into intricate designs, producing sharp, high-quality castings.

Refining and Recycling

The jewelry industry generates a significant amount of scrap, including sprues from casting, filings, and old jewelry. Induction furnaces are used to melt these materials into a single, uniform bar or ingot.

This consolidated form can then be accurately assayed to determine its exact precious metal content before being sold or reused.

Alloying New Metals

Artisans and manufacturers use induction furnaces to create custom alloys from pure metals. The precise control and self-stirring action are perfect for developing specific colors—like rose, green, or white gold—or for creating alloys with specific working properties.

Understanding the Trade-offs

While highly effective, induction technology is not a universal solution and comes with its own set of practical considerations.

Initial Investment and Infrastructure

Induction melting systems represent a significant capital investment compared to simple gas-and-oxygen torch setups. They also require specific electrical infrastructure to support their power demands.

Crucible Management

The ceramic or graphite crucible that holds the metal is a consumable item. It must be carefully selected for the specific metal being melted to prevent chemical reactions or contamination. Crucibles have a limited lifespan and can crack, requiring careful inspection and regular replacement.

Scale of Operation

Induction furnaces are designed for melting bulk material, from a few ounces to many kilograms at a time. They are not practical or efficient for small, individual repairs or workbench soldering, where a precision torch remains the superior tool.

Making the Right Choice for Your Goal

Selecting the appropriate melting technology depends entirely on the scale, purpose, and financial scope of your operation.

- If your primary focus is high-volume casting and manufacturing: An induction furnace is the industry standard for ensuring repeatable quality, speed, and efficiency.

- If your primary focus is refining scrap or creating consistent alloys: Induction is the superior choice for its ability to produce a clean, homogenous melt essential for accurate analysis and quality control.

- If your primary focus is small-scale artisan work or bench repairs: A traditional torch setup is often more practical and cost-effective for single-piece work and detailed soldering tasks.

By understanding its core principles, you can leverage induction technology to maximize the quality, efficiency, and value of your precious metal operations.

Summary Table:

| Key Advantage | Benefit for Jewelry & Precious Metals |

|---|---|

| Contact-Free Heating | Eliminates contamination, preserving metal purity and value. |

| Rapid Melting | Reduces oxidation and material loss, saving costs. |

| Self-Stirring Effect | Ensures homogenous alloys for consistent color and quality. |

| Precise Temperature Control | Ideal for intricate casting and custom alloy creation. |

Maximize the quality and value of your precious metal operations with KINTEK's advanced melting solutions. Leveraging exceptional R&D and in-house manufacturing, we provide jewelers and refiners with robust, high-performance induction melting furnaces tailored for gold, silver, platinum, and their alloys. Our deep customization capabilities ensure your furnace meets the exact demands of your workflow, whether for high-volume casting, scrap recycling, or precise alloy development. Contact our experts today to discuss how we can enhance your melting process!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control