From a technical standpoint, the primary challenges of vacuum and protective atmosphere induction furnaces are rooted in creating and maintaining a highly controlled environment under extreme thermal stress. These furnaces demand exceptional sealing integrity, sophisticated vacuum and gas management systems, specialized induction coil designs, and a higher level of operational discipline compared to standard air-melting furnaces.

The core challenge is not simply heating the metal, but preventing any undesirable interaction between the hot material and its surroundings. Every technical hurdle—from vacuum leaks to gas impurities—is a potential source of contamination that can compromise the final product's quality.

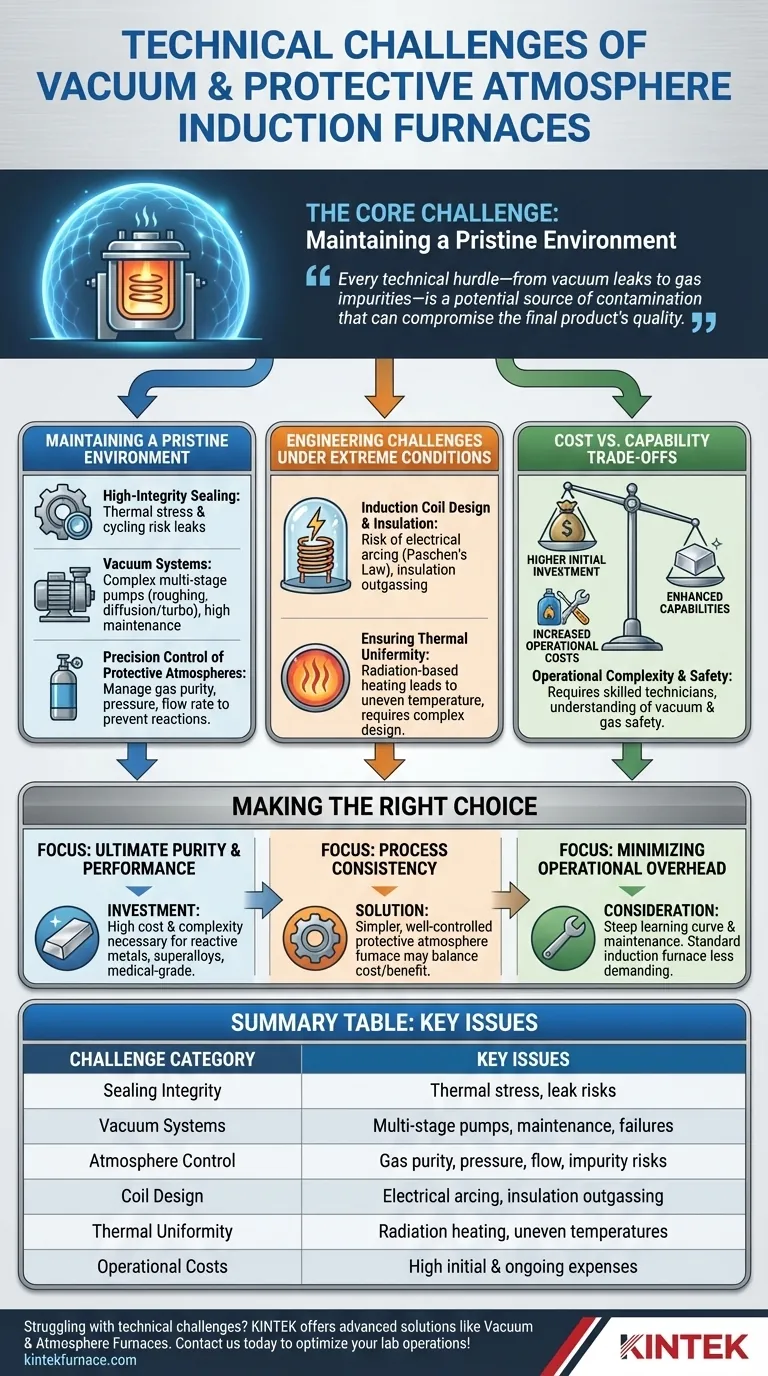

The Core Challenge: Maintaining a Pristine Environment

The fundamental purpose of these furnaces is to eliminate or precisely control the atmosphere a material is exposed to during heating. This introduces a new set of engineering problems focused entirely on isolation and control.

The Imperative of High-Integrity Sealing

A perfect seal is the first line of defense against contamination. The furnace chamber must be hermetically sealed to prevent oxygen and other atmospheric gases from entering.

This is difficult because thermal cycling causes materials to expand and contract, putting immense stress on seals, flanges, and joints. A minor leak that is negligible at room temperature can become a significant source of oxidation at high temperatures.

The Complexity of Vacuum Systems

Achieving a high vacuum is not a simple matter of flipping a switch on a single pump. It requires a multi-stage system of pumps, valves, and gauges working in perfect concert.

A typical system might include a roughing pump to remove the bulk of the air, followed by a diffusion or turbomolecular pump to achieve high vacuum levels. Each component is a potential point of failure and requires specialized maintenance, from regular oil changes to complex rebuilds.

Precision Control of Protective Atmospheres

When using a protective atmosphere like argon or nitrogen, the challenge shifts from removing gases to managing them. The system must precisely control gas purity, pressure, and flow rate.

Even trace amounts of impurities in the supply gas can react with the molten metal. Furthermore, the partial pressure of the gas must be carefully managed to prevent unwanted plasma effects or to control the evaporation of certain elements from the alloy.

Engineering Challenges Under Extreme Conditions

The unique internal environment of these furnaces creates specific design constraints for the core heating components.

Induction Coil Design and Insulation

In a standard furnace, the induction coil is outside the heating zone. In many vacuum furnaces, the coil is inside the chamber, exposing it directly to the vacuum or controlled atmosphere.

This introduces two major risks. First, at certain vacuum pressures, the risk of electrical arcing between the coil turns increases dramatically (an effect described by Paschen's Law). Second, the insulation materials on the coil can outgas, releasing contaminants that ruin the vacuum and spoil the material batch.

Ensuring Thermal Uniformity

A vacuum eliminates heat transfer through convection. This means heat moves primarily through radiation, which can lead to uneven heating, especially in large or complex-shaped parts processed in a batch.

Achieving a uniform temperature throughout the workload requires careful induction coil design and sophisticated power control to compensate for these altered heat transfer dynamics.

Understanding the Trade-offs: Cost vs. Capability

The enhanced capabilities of these furnaces come at a significant cost, both in capital and operational expenditure.

Higher Initial Investment

Vacuum and atmosphere furnaces are substantially more expensive than their open-air counterparts. The cost is driven by the vacuum-tight chamber, the complex pumping and gas-handling systems, and the advanced process controllers required for safe and repeatable operation.

Increased Operational Costs

Energy consumption is only one part of the operational cost. The continuous use of high-purity inert gases, consumables like vacuum pump oil, and the need for spare parts for complex subsystems add significant ongoing expense.

Operational Complexity and Safety

Operating these systems requires a higher level of skill and training. Technicians must understand vacuum principles, gas safety protocols, and complex troubleshooting procedures. A mistake can lead not only to a ruined batch of expensive material but also to safety hazards related to high pressures and electrical systems.

Making the Right Choice for Your Application

The decision to adopt this technology hinges on a clear understanding of your material requirements and operational capabilities.

- If your primary focus is ultimate material purity and performance: The high cost and complexity are a necessary investment to prevent oxidation and contamination in reactive metals, superalloys, or medical-grade materials.

- If your primary focus is process consistency for standard alloys: A simpler, well-controlled protective atmosphere furnace may offer a better balance of cost and benefit than a high-vacuum system.

- If your primary focus is minimizing operational overhead: The steep learning curve and specialized maintenance must be factored into your budget and staffing plans; a standard induction furnace is far less demanding.

Ultimately, success with these advanced furnaces depends on treating the entire system—not just the furnace itself—as a critical part of your quality control process.

Summary Table:

| Challenge Category | Key Issues |

|---|---|

| Sealing Integrity | Thermal stress on seals, risk of leaks and contamination |

| Vacuum Systems | Multi-stage pumps, maintenance needs, potential failures |

| Atmosphere Control | Gas purity, pressure, flow rate management, impurity risks |

| Coil Design | Electrical arcing, insulation outgassing in vacuum |

| Thermal Uniformity | Radiation-based heating, uneven temperatures in batches |

| Operational Costs | High initial investment, ongoing expenses for gases and maintenance |

Struggling with technical challenges in your high-temperature processes? KINTEK is here to help! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing purity and efficiency in applications for reactive metals, superalloys, and more. Don't let complexity hold you back—contact us today to discuss how we can optimize your laboratory operations!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications