In essence, a vacuum induction furnace is used to melt, heat-treat, and refine materials in a highly controlled, oxygen-free environment. This process prevents unwanted chemical reactions like oxidation and removes impurities from the ingot material. The result is a final product with superior purity, enhanced physical properties, and a higher-quality finish.

The decision to use a vacuum furnace is not just about reaching high temperatures. It is a strategic choice to gain absolute control over the material's chemistry by eliminating the reactive elements in the air, ensuring the final product is as pure and structurally sound as theoretically possible.

The Core Function: Controlling the Environment

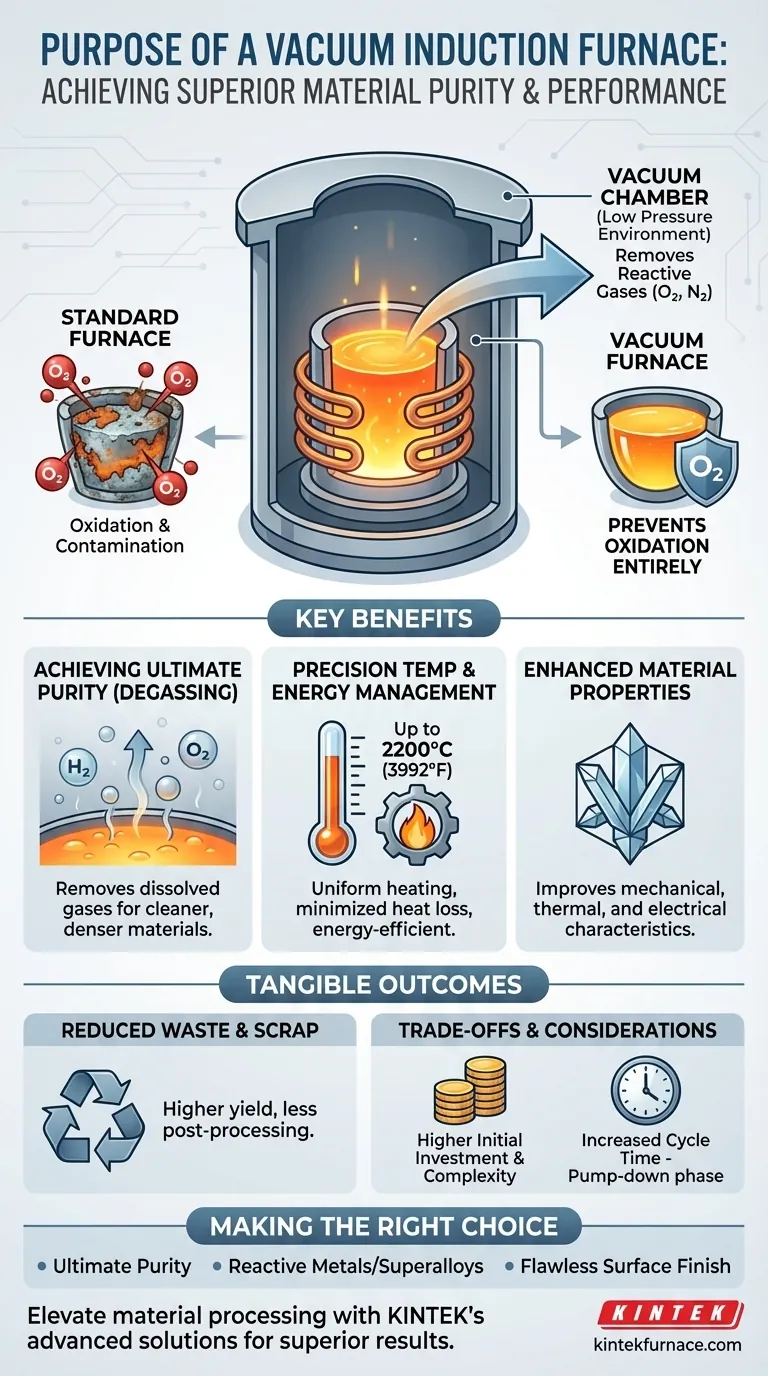

The fundamental advantage of a vacuum furnace is its ability to create a low-pressure environment. By removing air, you remove reactive gases like oxygen and nitrogen, which fundamentally changes how materials behave at high temperatures.

Preventing Oxidation and Contamination

In a standard furnace, oxygen in the air rapidly reacts with hot metal, forming oxides on the surface. This creates a layer of impurities, causes material loss, and can result in surface defects.

A vacuum furnace removes the oxygen, preventing oxidation entirely. This is critical for reactive metals and for applications, like jewelry, where a flawless surface finish is paramount.

Achieving Ultimate Material Purity

The vacuum does more than just prevent new contaminants from forming; it helps remove existing ones. The low-pressure environment encourages degassing, pulling dissolved gases like hydrogen and oxygen out of the molten material.

This process results in a cleaner, denser final product with fewer internal voids or porosity. The outcome is a material that is structurally stronger and more reliable.

Precision Temperature and Energy Management

These systems are designed for high-performance applications, capable of reaching temperatures up to 2200°C (3992°F).

They incorporate advanced insulation and closed-loop control systems. This not only allows for precise and uniform heating but also minimizes heat loss, making them more energy-efficient and cost-effective to operate compared to less-contained systems.

Tangible Benefits of a Controlled Process

Controlling the furnace environment translates directly into measurable improvements in the final product and the manufacturing process itself.

Enhanced Material Properties

By preventing the formation of inclusions (like oxides) and removing dissolved gases, the furnace produces a material with a more perfect crystalline structure.

This directly improves its mechanical, thermal, and electrical characteristics. The material becomes stronger, more ductile, and a better conductor, meeting the demanding specifications of high-tech industries.

Reduced Waste and Scrap

Because oxidation and surface defects are eliminated, the process yields a higher percentage of usable material from each batch.

This reduces scrap rates and the need for post-processing steps like grinding or polishing, saving both time and raw material costs.

Understanding the Trade-offs

While powerful, a vacuum furnace is a specialized tool with specific considerations. It is not the right choice for every application.

Higher Initial Investment and Complexity

Vacuum induction furnaces are mechanically complex systems. They require a significant capital investment compared to standard atmospheric furnaces due to the vacuum pumps, chamber, and control systems.

Increased Cycle Time

Achieving a deep vacuum takes time. The "pump-down" phase перед каждым циклом может увеличить общее время обработки по сравнению с более простыми печами, в которых не требуется вакуумирование.

Not Always a Necessity

For many common metals and alloys where slight oxidation is acceptable or even desirable for creating a protective patina, the expense and complexity of a vacuum furnace are unnecessary.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your final objective and the materials you are working with.

- If your primary focus is ultimate material purity and performance: A vacuum furnace is essential for removing dissolved gases and preventing the formation of strength-reducing impurities.

- If your primary focus is working with reactive metals or superalloys: The oxygen-free environment of a vacuum furnace is non-negotiable to prevent catastrophic oxidation and ensure material integrity.

- If your primary focus is a flawless surface finish and minimal material loss: The vacuum process is superior for creating net-shape parts that require little to no post-processing.

- If your primary focus is high-volume, low-cost melting of non-reactive metals: A simpler and less expensive atmospheric furnace is often the more economical and practical choice.

Ultimately, a vacuum induction furnace is a tool for precision, guaranteeing the material you design is the material you create.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Environment Control | Prevents oxidation and contamination by removing reactive gases like oxygen and nitrogen. |

| Material Purity | Enables degassing to remove dissolved gases, resulting in cleaner, denser materials. |

| Temperature Precision | Allows precise heating up to 2200°C with uniform temperature distribution and energy efficiency. |

| Enhanced Properties | Improves mechanical, thermal, and electrical characteristics for stronger, more reliable products. |

| Process Efficiency | Reduces waste and scrap, minimizing the need for post-processing and saving costs. |

Elevate your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum induction furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for achieving superior purity and performance. Contact us today to discuss how our tailored solutions can optimize your processes and deliver exceptional results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity